Full-automatic Liupao-tea-leaf fermenting jar and fermenting technology thereof

A fermentation process, Liubao tea technology, is applied in the field of Liubao tea and tea automatic fermentation tank and its fermentation process, which can solve the problems of difficulty in standardizing product quality, inability to add water, unstable pressure in the tank, etc., and reduce labor costs. and technical requirements of workers, preventing equipment failure or danger, and realizing the effect of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

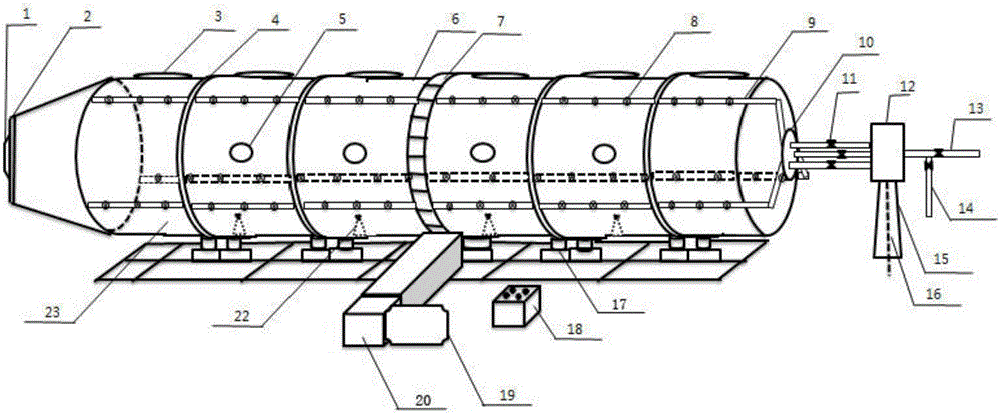

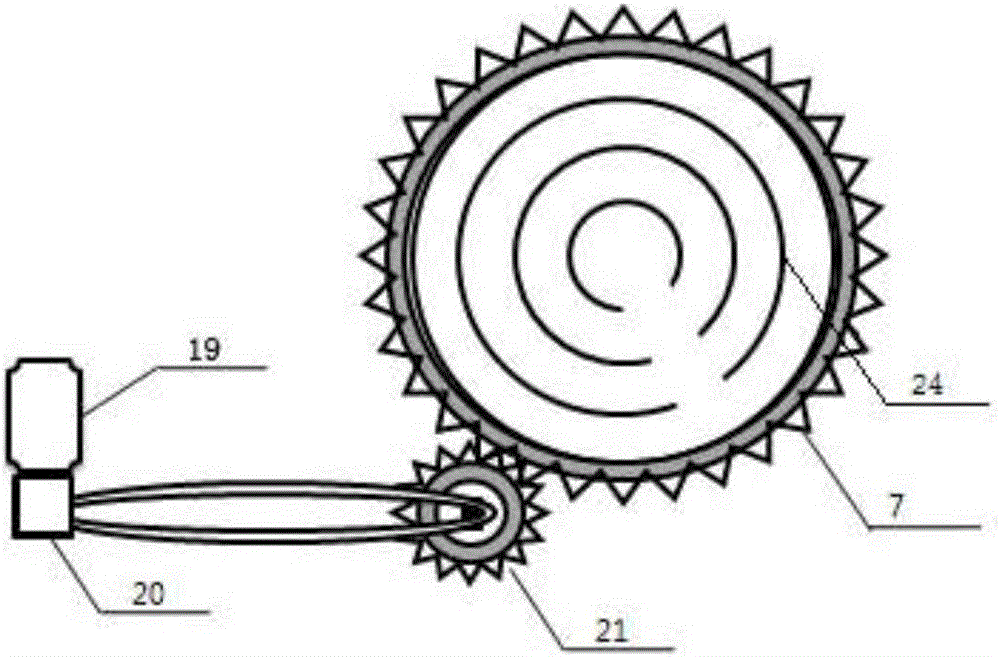

[0029] Referring to the accompanying drawings, a fully automatic fermenter for Liubao tea includes a tank body 6, a driving device and a control device. The side of the tank body 6 is provided with a plurality of feeding ports 3 and transparent windows 5, the inner side of the tank body 6 is provided with a spiral baffle plate 24, the outer layer of the tank body 6 is an insulating material layer 23, and the inner side of the tank body 6 is axially provided with Water and gas pipeline 9, the quantity of water and gas pipeline 9 is 3 groups, and each group of water and gas pipeline 9 is 120 ° evenly distributed in radial direction, and water and gas pipeline 9 is provided with high-pressure water and gas nozzle 8, and each high pressure water and gas nozzle 8 The axial distance is 0.8m. One end of the tank body 6 is provided with a discharge port 2 with a sealing cover. The sealing cover of the discharge port 2 is provided with a plurality of air holes 1. The diameter of the air...

Embodiment 2

[0039] A fully automatic fermenter for Liubao tea includes a tank body 6, a driving device and a control device. The side of the tank body 6 is provided with a plurality of feeding ports 3 and transparent windows 5, the inner side of the tank body 6 is provided with a spiral baffle plate 24, the outer layer of the tank body 6 is an insulating material layer 23, and the inner side of the tank body 6 is axially provided with Water and gas pipeline 9, the quantity of water and gas pipeline 9 is 4 groups, and every group of water and gas pipeline 9 is evenly distributed in 90 ° in radial direction, and water and gas pipeline 9 is provided with high pressure water and gas nozzle 8, and each high pressure water and gas nozzle 8 The axial spacing distance is 1m, and one end of the tank body 6 is provided with a discharge port 2 with a sealing cover, and the sealing cover of the discharge port 2 is provided with a plurality of air holes 1, and the diameter of the air hole 1 is 2mm. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com