Depth-adjustable livestock and poultry manure turner

An adjustable technology for livestock and poultry manure, which can be used in organic fertilizers, climate change adaptation, fertilization devices, etc. Fermentation, increasing the contact area of feces, and good effect of turning over and throwing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

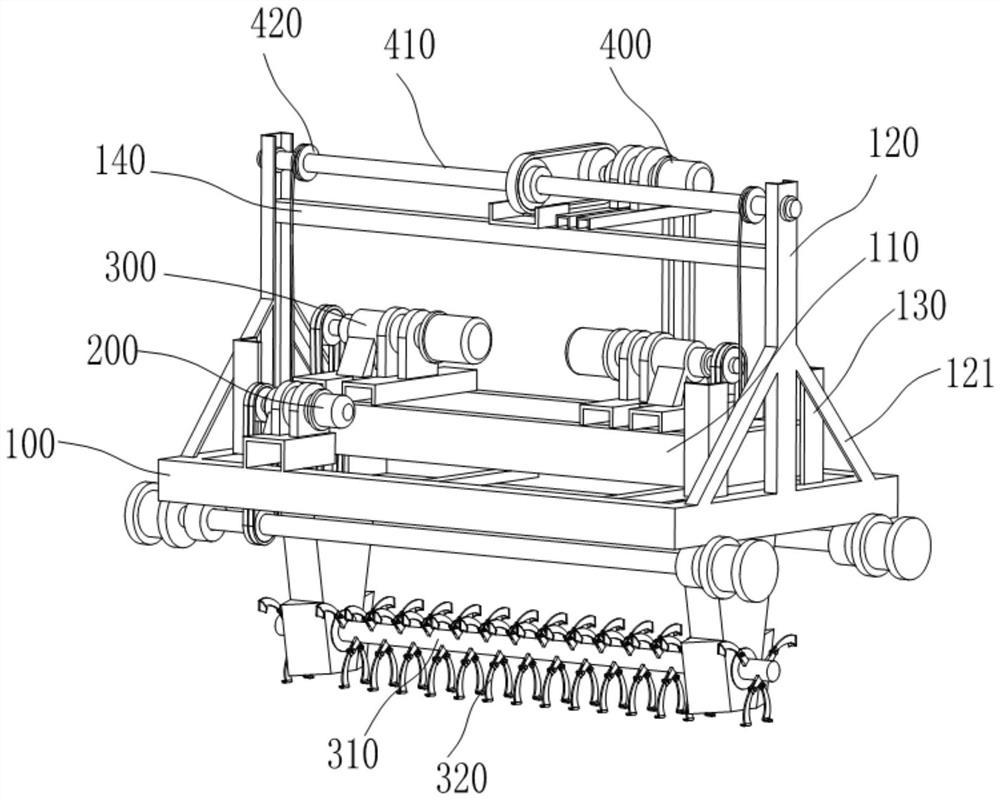

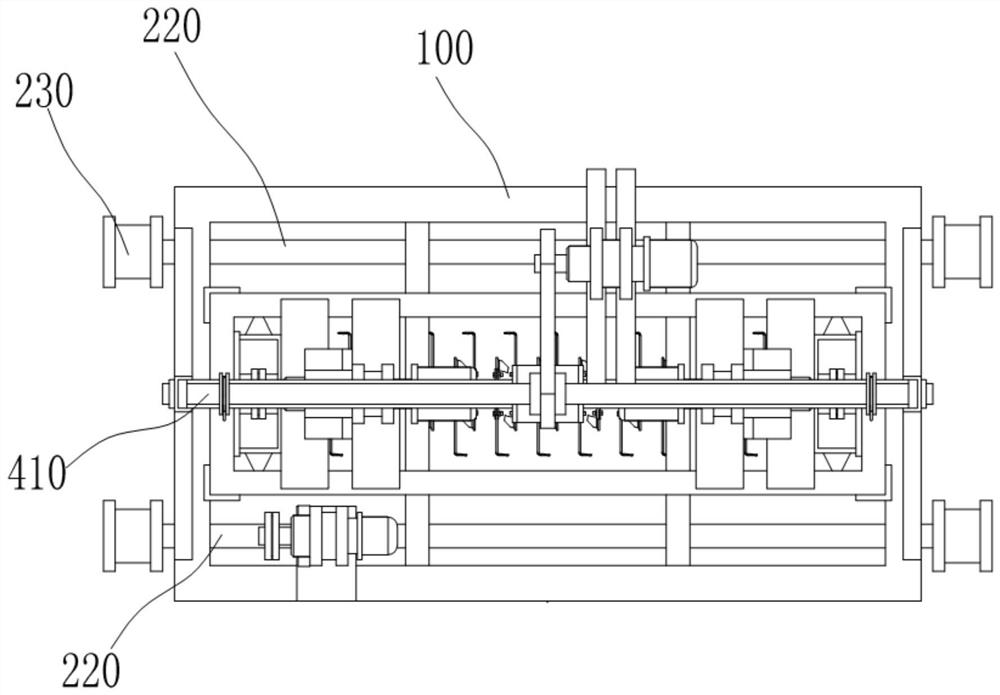

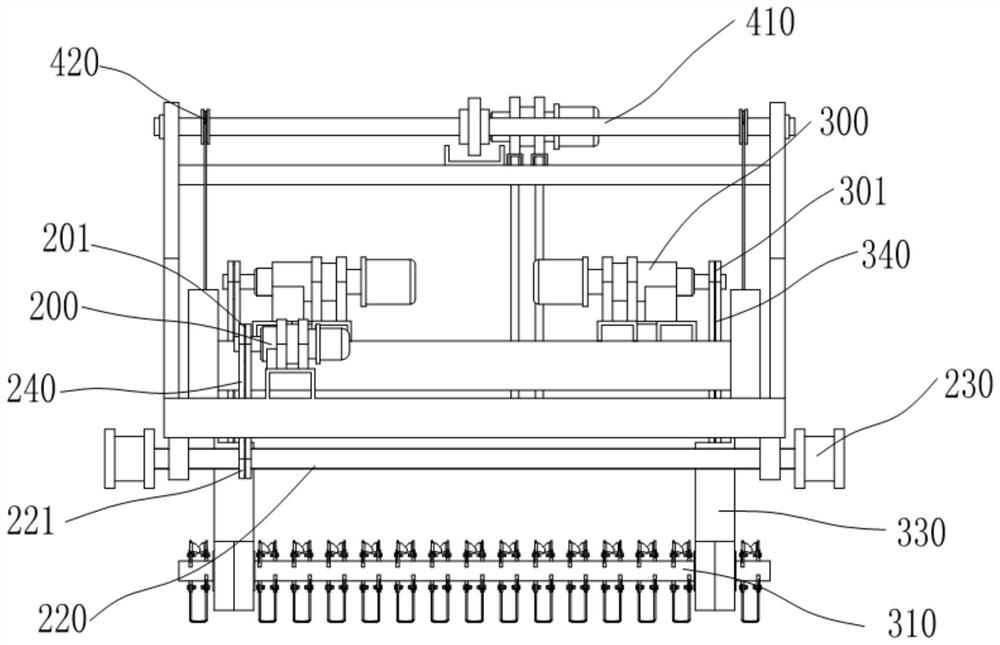

[0028] see Figure 1-6, the present invention provides a technical solution: a depth-adjustable livestock and poultry manure turning and throwing machine, including a work frame 100, a moving mechanism, a turning and throwing mechanism, and a lifting mechanism. The work frame 100 is a rectangular frame, and the inside of the work frame 100 is horizontal. A baffle 150 is provided, and a platform 110 is movable above the baffle 150. The baffle 150 plays a role of supporting and limiting the platform 110, so that the height of the platform 110 relative to the working frame 100 matches the depth of the cesspool, and the working frame 100 is positioned on the platform. Two sets of support rods 120 are arranged on both sides of 110, and two sets of support rods 120 are provided with reinforcement rods 121 to connect with the work frame 100, and the reinforcement rods 121 improve the connection strength of the two groups of support rods 120 on the work frame 100 and improve the stabil...

Embodiment 2

[0034] On the basis of Example 1, please refer to Figure 1-7 , a plurality of turning and throwing tooth groups 320 are arranged at cross intervals on the turning and throwing shaft 310, and two adjacent turning and throwing tooth groups 320 are perpendicular to each other, so that when the turning and throwing tooth groups 320 are rotated to turn over the excrement, the The contact area between the throwing tooth group 320 and the feces is evenly turned over to the feces, so that the feces are fully contacted with oxygen, and the fermentation effect of the feces is further improved. The turning tooth group 320 includes a tooth handle 321 and a turning tooth 322. There are slots, and the flipping teeth 322 are plugged into the slots of the tooth handle 321 and fixed by bolts 323. The flipping teeth 322 are detachably connected on the tooth handle 321, so that part of the flipping teeth 322 does not need to be replaced when they are damaged. The entire turning and throwing sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com