Decomposition system and method for high water content construction dregs

A technology of construction dregs and high water content, which is applied in chemical instruments and methods, transportation and packaging, etc., can solve the problems of high water content of construction dregs, great weather influence, and difficult decomposition, so as to improve environmental quality and weather impact Effect of small size and expanded production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

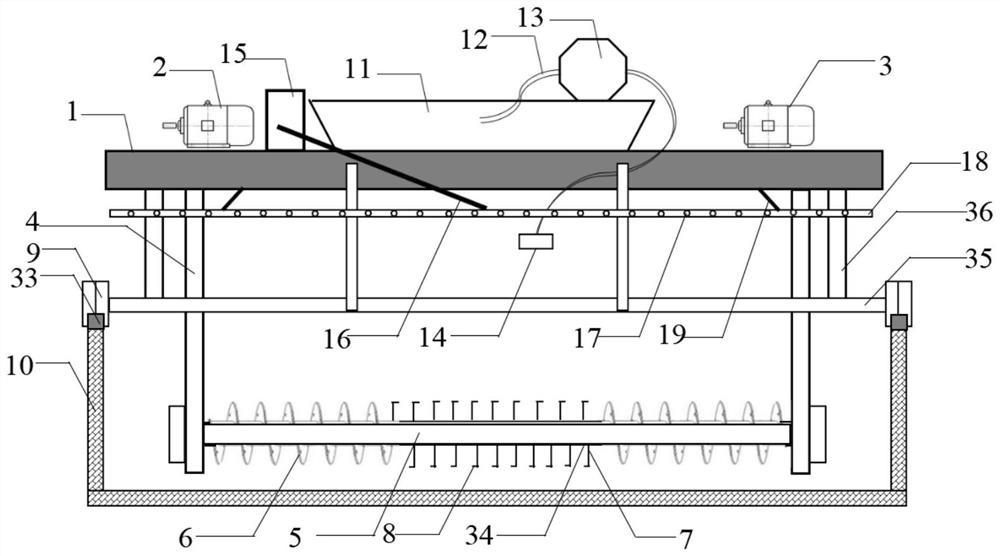

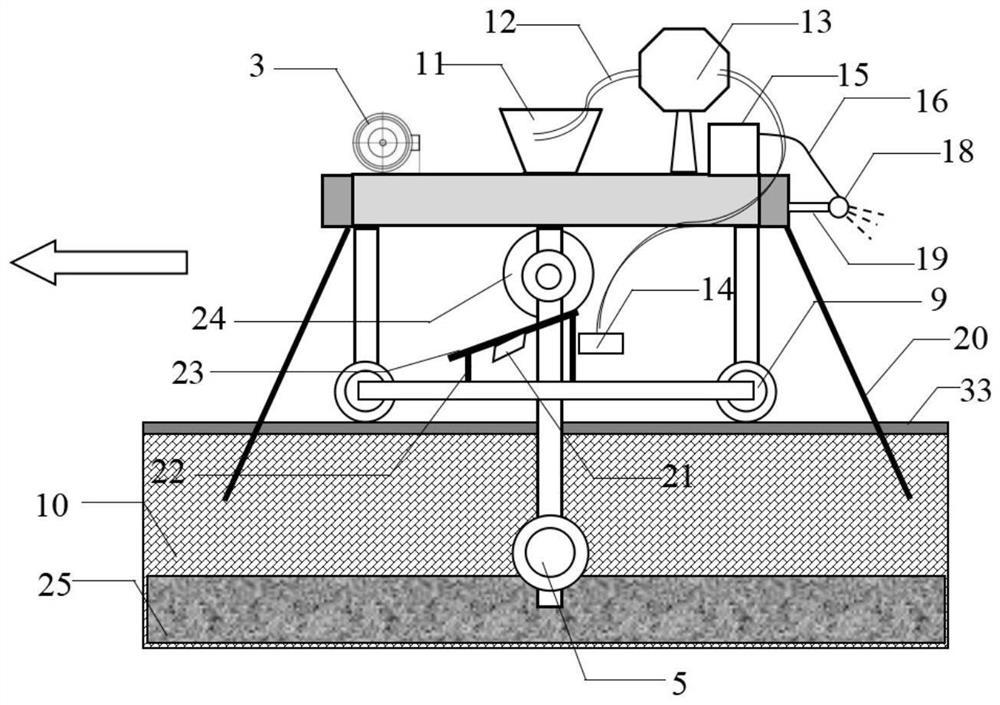

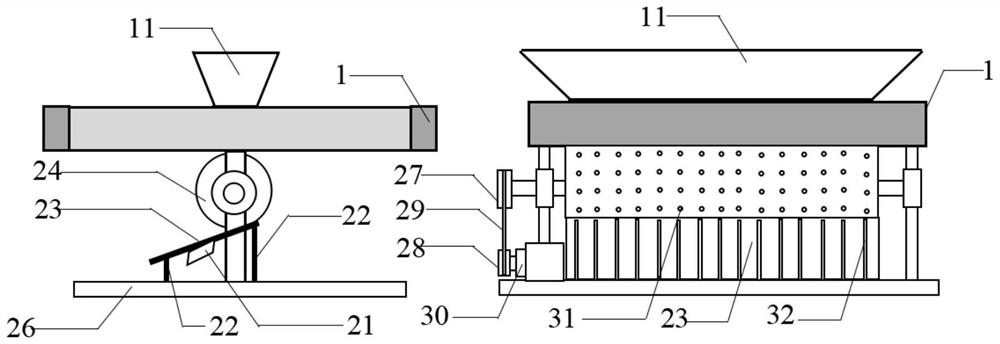

[0045] like Figure 1-4 As shown, the high-water content construction slag decomposition system includes a turning machine host, a turning device, an automatic material spreading system, a dust suction system, a spraying system and a control system.

[0046] like Figure 1-3 The main engine of the flipping machine shown includes a flipping machine bracket 1 and a walking drive motor 3; the flipping machine support includes a cross beam 35 and a vertical beam 36, the cross beam and the vertical beam are connected by bolts, and a series of The connecting rods make the turning machine bracket 1 stable and have a large bearing capacity; the two groups of walking rollers 9 arranged in front and rear on both sides of the turning machine bracket 1 are arranged on the track 33 on the support structure 10, and the walking rollers 9 support On the track, the support is driven to move back and forth along the track, and the turning machine support 1 is erected above the construction was...

Embodiment 2

[0060] The main steps of the decomposition method of the decomposition system of the high-water content construction slag include:

[0061] S1. Construction muck paving. After the construction muck is transported to the disposal site, the muck truck reverses and unloads the soil within the range of the trough along the traveling direction of the dumper and the disintegration system. , so that the height of its loose paving does not exceed 0.8m. During this process, the turner and disintegration system should be moved away from the direction of unloading.

[0062] S2, the ratio of powder curing material. According to the leveled construction muck height and groove width, calculate the square quantity of construction muck per unit area, and determine the surface powder of construction muck per unit area according to the percentage of the powder solidified material in this type of construction muck. The amount of solidified material applied.

[0063] S3. Powder solidifying ma...

Embodiment 3

[0068] This embodiment relies on the future city science center project in Fenghua District, Ningbo, which is a comprehensive urban public service project integrating planning and exhibition, academic research, cultural exchange, educational practice, business leisure and other functions, covering an area of 56,777 square meters. The building area is about 19,000 square meters. Excavation of large-scale foundation pits in the project will generate a large amount of engineering slag. According to the previous sampling and test results, the slag in the site is mainly soft soil with a moisture content of more than 40%. Therefore, the decomposition test was carried out by taking the construction waste of this project as an example. Proceed as follows:

[0069] (1) Paving construction waste. Two trucks of construction waste used for the test, about 40m 3 , After the construction waste is transported to the disposal test site, the soil is unloaded and stacked into a stack, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com