Method for preparing antioxidant product from scallop skirts

A scallop skirt, anti-oxidation technology, applied in food hydrolysis, food science, etc., can solve the problem of low added value of products, and achieve the effect of improving antioxidant capacity, improving utilization rate, and high antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1. Take the scallop skirt, wash it, heat it in a water bath at 100°C for 10 minutes for denaturation treatment, cool, freeze-dry, and pulverize to obtain the scallop skirt freeze-dried powder;

[0028] S2, using neutral protease and papain as tool enzymes respectively, enzyme dosage 3000U / g protein, substrate concentration (calculated as protein) 4g / 100mL, constant pH 7, enzymolysis temperature 50 ℃ enzymolysis conditions on scallop skirt The freeze-dried powder is subjected to enzymatic hydrolysis treatment; the enzymatic hydrolysis time is 0.5h, 1h, 2h, and 3h respectively. After enzymolysis, inactivate the enzyme in a water bath at 100°C for 10 minutes, centrifuge at 4000×g for 10 minutes, take the supernatant and freeze-dry to obtain 8 kinds of scallop skirt enzymatic hydrolyzate freeze-dried powder; The scavenging ability of DPPH free radicals is measured by the half-inhibition rate of DPPH free radicals (IC 50 ) as an index to screen the optimal enzymatic hydrol...

Embodiment 2

[0039] S1. Take the scallop skirt, wash it, heat it in a water bath at 100°C for 10 minutes for denaturation treatment, cool, freeze-dry, and pulverize to obtain the scallop skirt freeze-dried powder;

[0040] S2. Carry out enzymatic hydrolysis in the optimal mode, using neutral protease, enzyme dosage 3000U / g protein, substrate concentration (calculated as protein) 4g / 100mL, constant pH 7, enzymolysis temperature 50 ℃ under enzymolysis conditions The scallop skirt freeze-dried powder was subjected to enzymatic hydrolysis treatment, and the enzymatic hydrolysis time was 2 hours. After enzymolysis, inactivate the enzyme in a water bath at 100°C for 10 minutes, centrifuge at 4000×g for 10 minutes, take the supernatant and freeze-dry to obtain the lyophilized powder of scallop skirt enzymatic hydrolyzate;

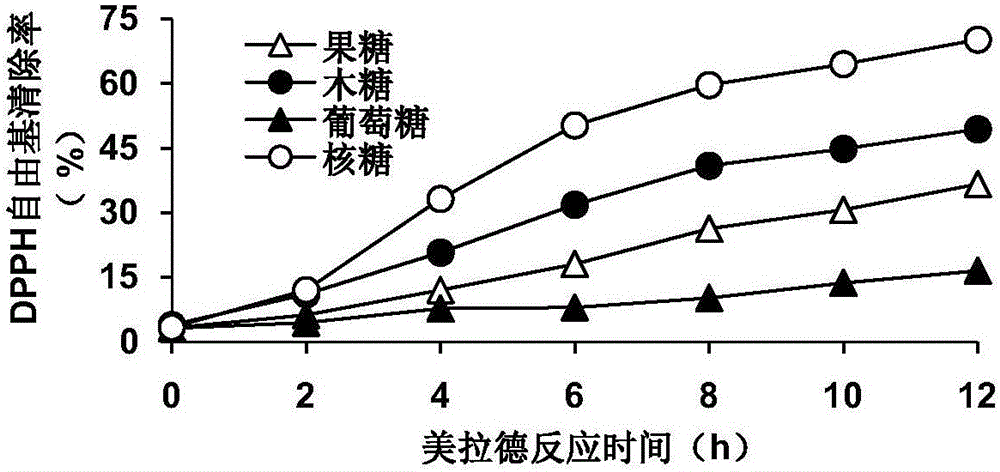

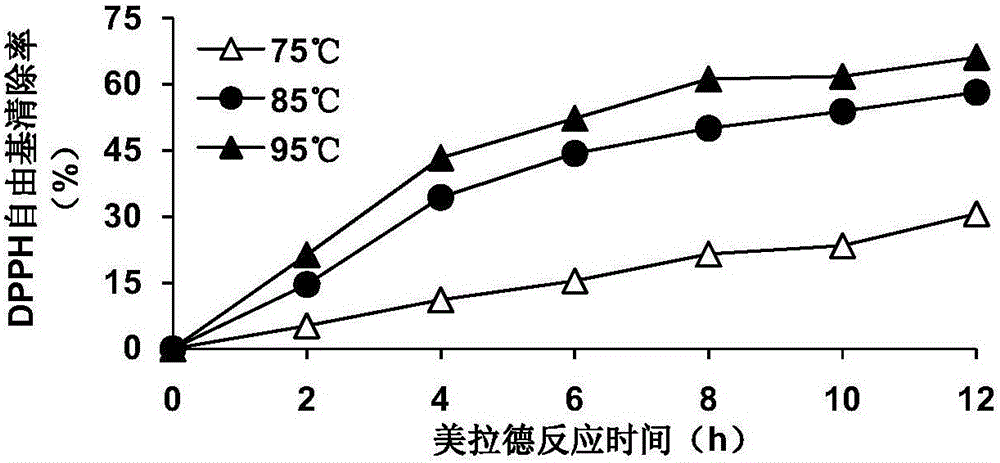

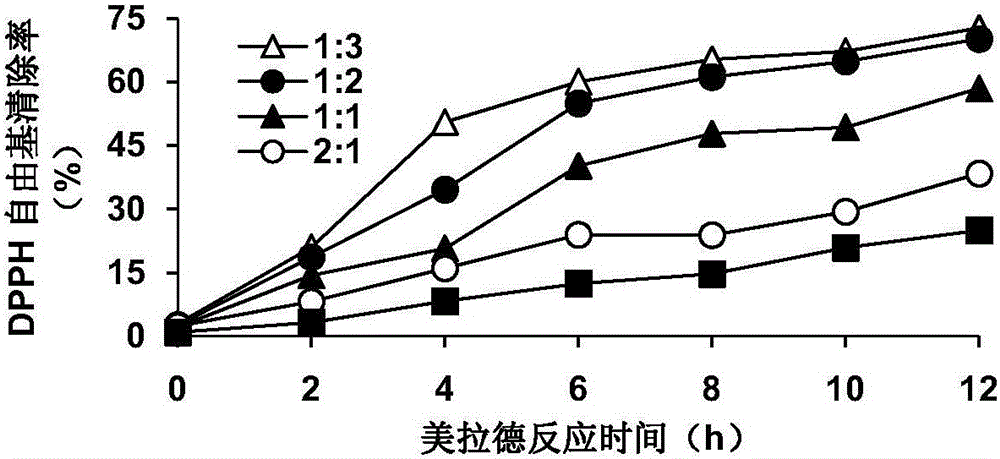

[0041] S3. Carry out Maillard reaction modification to the enzymolyzate prepared under the optimal enzymolysis conditions described in S2. The reducing sugars are ribose, xylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com