Monitoring and managing system for flue gas desulfurization and denitration process

A management system and process monitoring technology, applied in the denitration process monitoring and management system and the field of flue gas desulfurization, can solve the problems of unwillingness to desulfurization transformation of power plants, low-price bidding, high operating costs, large engineering investment, etc., to ensure scientific and Safety, Ease of Judgment and Statistical Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

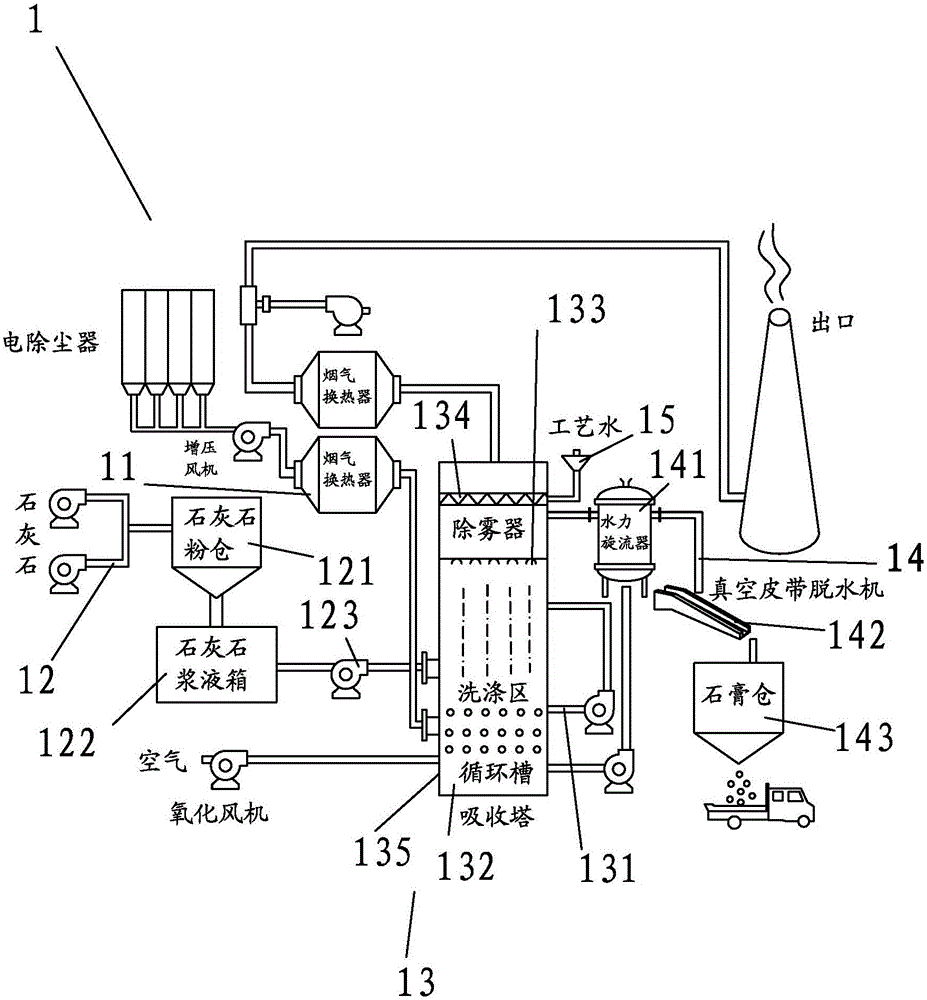

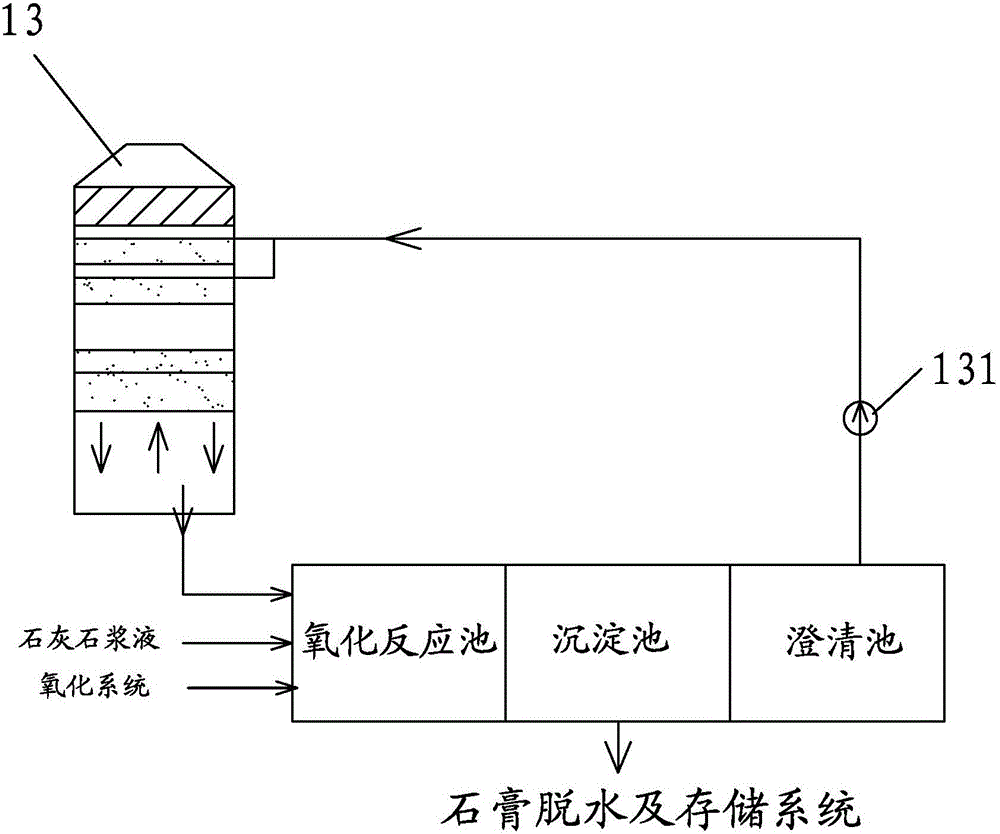

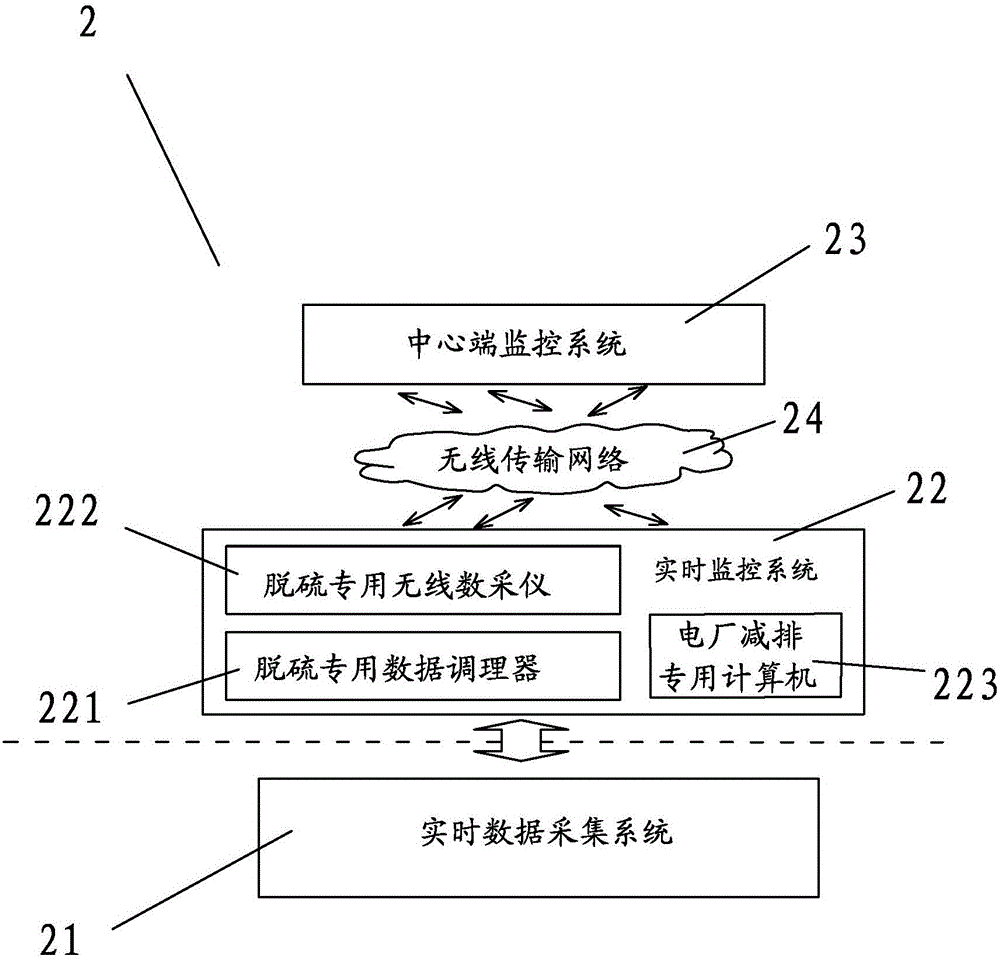

[0063] The flue gas desulfurization method in the present invention adopts a conventional limestone-gypsum wet desulfurization process.

[0064] Such as Figure 1-3 As shown, a flue gas desulfurization process monitoring and management system in the present invention includes a flue gas desulfurization system 1 and a monitoring and management system 2 . The monitoring management system 2 monitors the operation process of the flue gas desulfurization system 1 . The flue gas desulfurization system includes a flue gas system 11, a limestone slurry preparation and delivery system 12, an absorption tower system 13, a gypsum dehydration and storage system 14, a process water system 15, a compressed air system, and an electrical instrument and control system.

[0065] The outlet flue of the flue gas system 11 is connected to the flue gas inlet of the absorption tower system 13, the outlet pipe of the limestone slurry preparation and delivery system 12 is connected to the slurry inle...

Embodiment 2

[0088] The flue gas denitration method in the present invention adopts a conventional SCR denitrification process, and the SCR catalyst adopts an ammonia catalyst.

[0089] In coal-fired boilers, due to the high dust content in the flue gas, vertical airflow is generally used. Such as Figure 4 and 5 As shown, a flue gas denitrification process monitoring and management system in the present invention includes a flue gas denitrification system 3 and a monitoring management system 4 . The monitoring management system 4 monitors the operation process of the flue gas denitrification system 3 . The flue gas denitrification system 3 includes an SCR reactor 31 connected by pipelines, an ammonia storage and supply system 32, an ammonia / air spray system 33, and related SCR control systems. The outlet pipe of the ammonia storage and supply system 32 is connected to the ammonia gas inlet of the ammonia / air spray system 33 , and the outlet pipe of the ammonia / air spray system 33 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com