Power motor auxiliary gear shifting control system and method

A power motor and control system technology, applied in the field of power motor auxiliary shift control system, can solve the problems of DC bus voltage impact, affecting the gear shift quality of the gearbox, and the service life of the power battery, so as to slow down the voltage drop and shorten the shift time , Improve the effect of shifting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

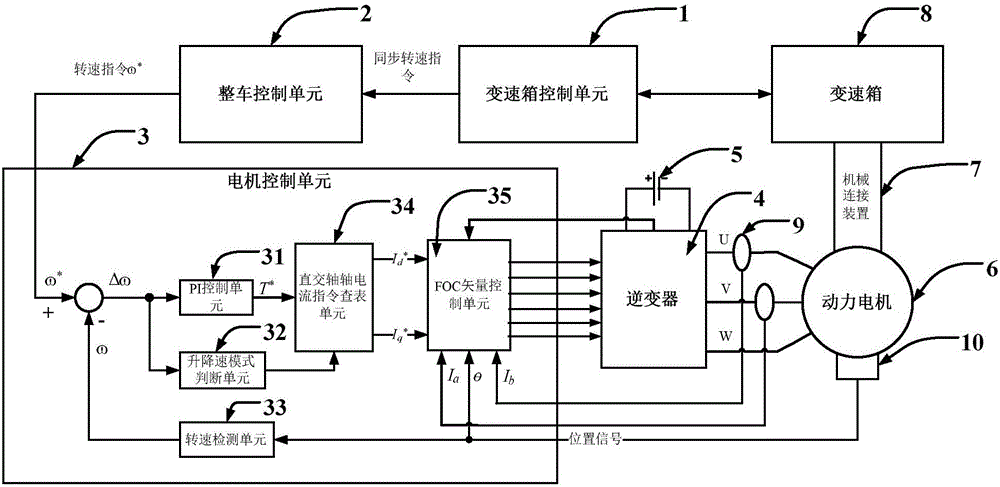

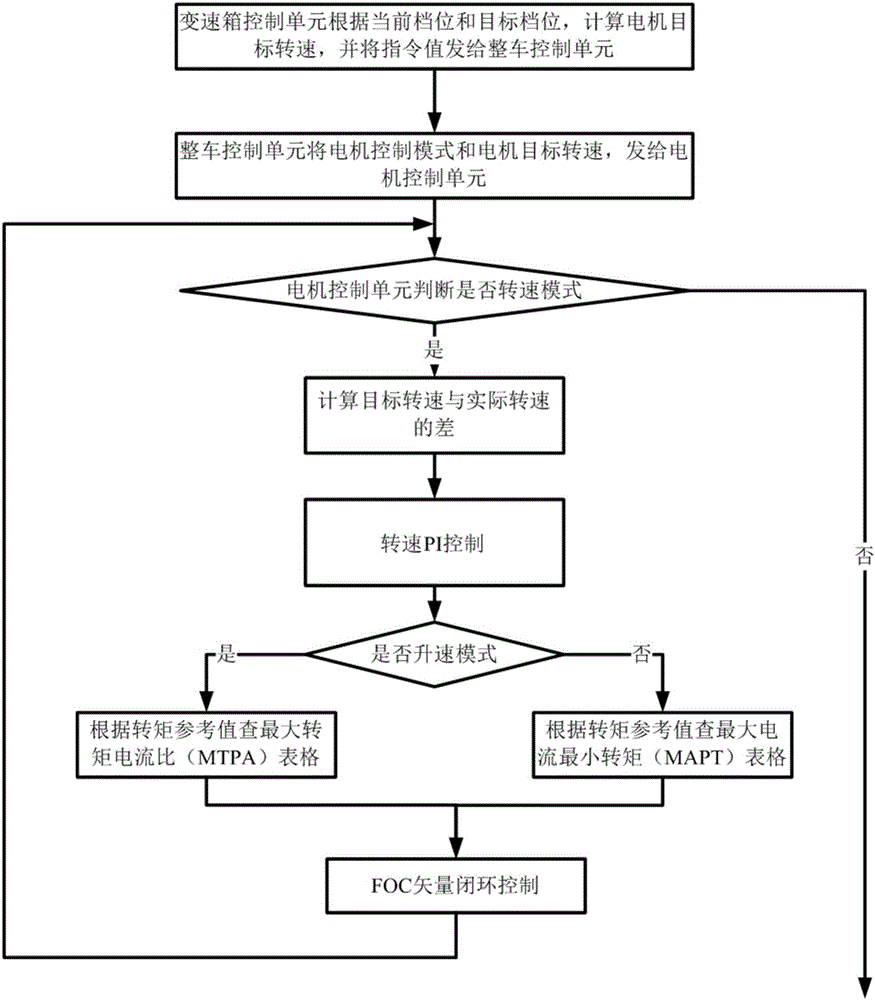

[0042] Such as figure 1 As shown, a power motor auxiliary shift control system includes a gearbox control unit 1, a vehicle control unit 2, a motor control unit 3, an inverter 4, a phase current sensor 9, a position sensor 10, a power battery 5, and a power motor 6. Mechanical connection device 7 and gearbox 8;

[0043] The transmission control unit 1 is responsible for calculating the synchronous speed according to the current gear and the target gear, and sends a shift request and a synchronous speed command to the vehicle control unit;

[0044] The vehicle control unit 2 is responsible for receiving the shift request and synchronous speed from the gearbox control unit 1, and forwarding the speed command ω* to the motor control unit 3,

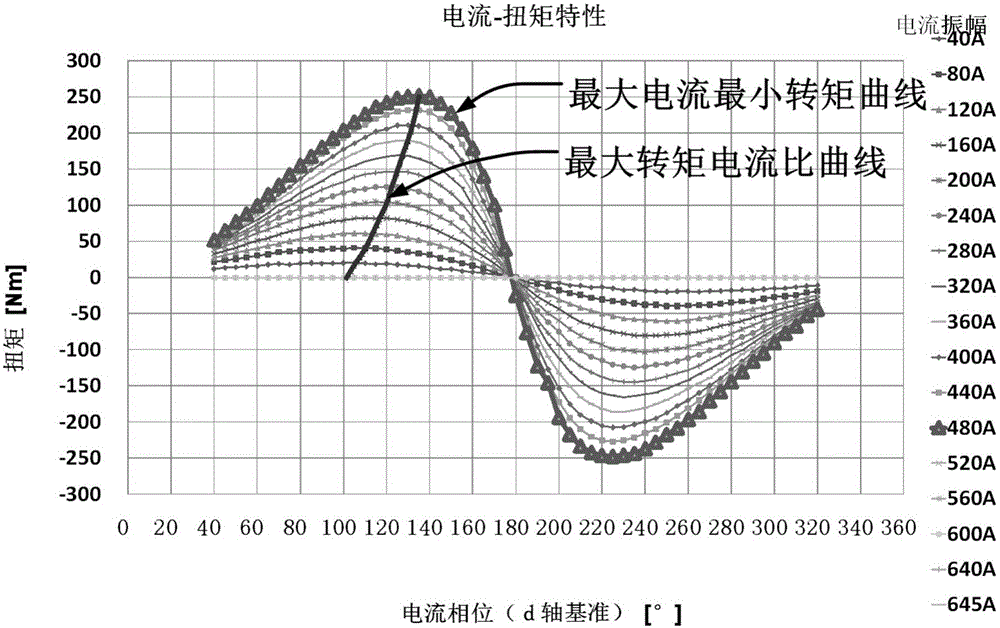

[0045] The motor control unit 3 includes a rotational speed detection unit 33, a PI control unit 31, a speed-up / down mode judgment unit 32, a rectangular axis current command look-up unit 34, and a field oriented vector (Field Oriented Cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com