Photocatalytic inorganic ecological decoration board and production method thereof

The technology of a decorative sheet and a production method, which is applied in the field of photocatalytic ecological decorative sheet, can solve the problems of uneven dispersion of nano-based titanium dioxide composite photocatalyst and utilization of low added value, etc., and achieve the effect of improving the quality of space environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

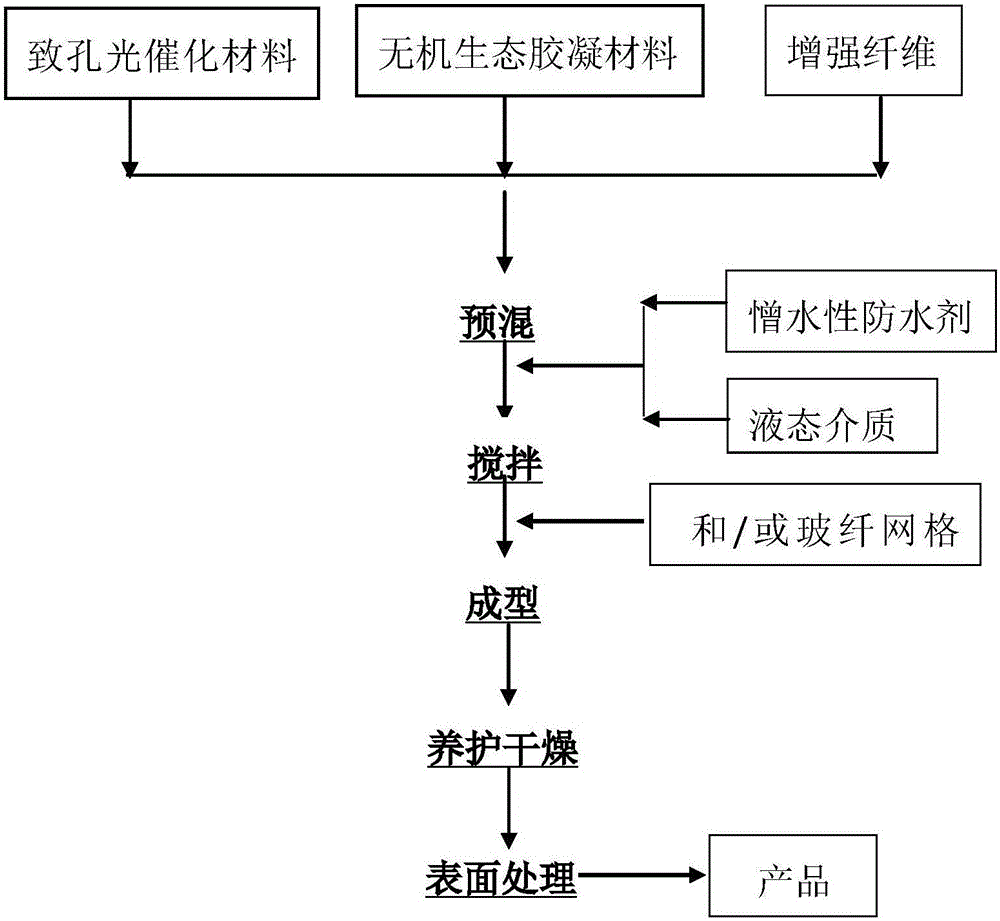

Method used

Image

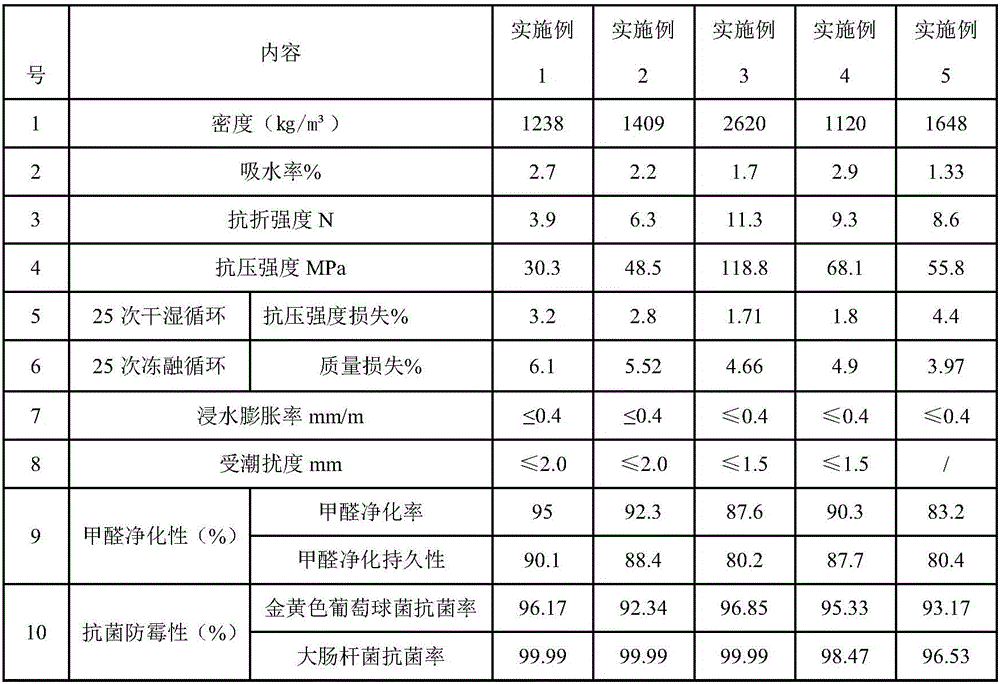

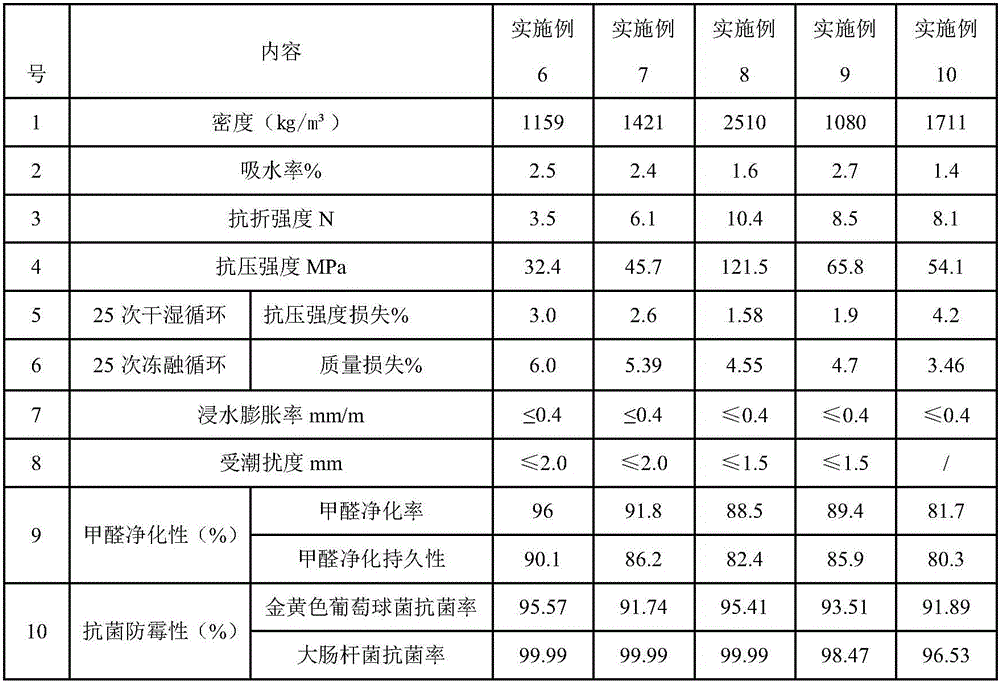

Examples

Embodiment 1

[0040] The ecological decorative panel in this embodiment is the ceiling ecological decorative panel

[0041] 1. The formula composition by weight parts:

[0042] 1.8 parts of porogenic photocatalytic material: composed of La 1-x Sr x MO 3 type nanocatalysts (LaMnO 3 Nanoparticles), porogen (sodium lauryl sulfate K12), and water are compounded at a weight ratio of 5:1:94;

[0043] 100 parts of inorganic ecological gelling powder: 84 parts of inorganic gelling materials (80 parts of natural β-hemihydrate gypsum, 4 parts of Portland cement) and 16 parts of ecological mineral powder (8 parts of diatomite, tourmaline anion 3 parts of powder, 5 parts of attapulgite powder) compounded;

[0044] 1.5 parts of reinforcing fiber: glass fiber with a length of 15-18 mm;

[0045] 1.5 parts of hydrophobic water repellent: sodium methyl siliconate;

[0046] 68 parts of liquid medium: obtained by compounding water, polyvinyl alcohol, sodium citrate, and aluminum potassium sulfate in a ...

Embodiment 2

[0055] The ecological decorative board in this embodiment is a wall board ecological decorative board

[0056] 1. The formula composition by weight parts:

[0057] 5.5 parts of porogenic photocatalytic material: composed of La 1-x Sr x MO 3 type nanocatalysts (La 0.6 Sr 0.4 MnO 3 Nanoparticles), porogen (sodium lauryl sulfate), and water are compounded at a weight ratio of 10:4:86;

[0058] 100 parts of inorganic ecological gelling powder: 80 parts of inorganic gelling materials (7 parts of natural α-hemihydrate gypsum, 63 parts of natural β-hemihydrate gypsum, 10 parts of white Portland cement) and 20 parts of ecological mineral powder (15 parts of diatomite, 3.0 parts of tourmaline negative ion powder, 2.0 parts of attapulgite powder).

[0059] 13.5 parts of reinforcing fiber: 1.5 parts of glass fiber, 12 parts of mineral fiber (in each embodiment of the present invention, the length of glass fiber is 15-18 mm, and the length of mineral fiber is 70 μm-120 μm);

[0060]...

Embodiment 3

[0070] The ecological decorative plate in this embodiment is a stone-like ecological decorative plate

[0071] 1. The formula composition by weight parts:

[0072] 3.8 parts of porogenic photocatalytic material: composed of La 1-x Sr x MO 3 type nanocatalyst (LaCoO 3 Nanoparticles), porogen (sodium lauryl sulfate), and water in a weight ratio of 50:5:45;

[0073] 100 parts of inorganic ecological gelling powder: 87 parts of inorganic gelling material (80 parts of natural α-hemihydrate gypsum, 7.0 parts of white Portland cement), 13 parts of ecological mineral powder (5 parts of diatomaceous earth, vermiculite powder 3.0 parts, tourmaline anion powder 3.0 parts, zeolite powder 2.0 parts), obtained by compounding.

[0074] 10 parts of reinforcing fiber: 2 parts of glass fiber, 8 parts of mineral fiber;

[0075] 1.8 parts of hydrophobic water repellent: potassium methyl siliconate;

[0076] 20.8 parts of liquid medium: It is obtained by compounding water and polyvinyl alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com