Sandwiched phthalocyanine rare-earth complex with two-photo absorption property and preparation method thereof

A technology of rare earth complexes and two-photon absorption, applied in optics, organic chemistry, nonlinear optics, etc., to achieve good solubility and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

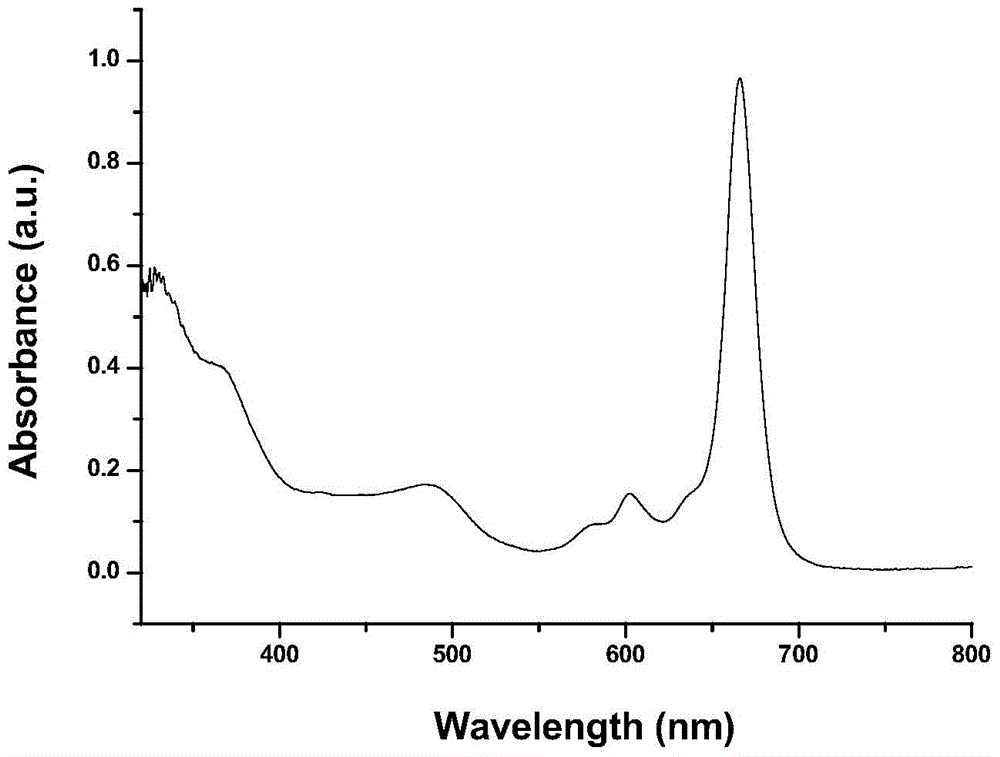

[0027] Weigh 0.46g of yttrium acetylacetonate hydrate and 0.51g of o-dicyanobenzene into a sealed reactor, add 5mL of n-pentanol and 12 drops of catalyst DBU, and heat and stir at 100°C for 2 hours under nitrogen protection. After the product is cooled, the n-pentanol is distilled off. Dissolve the solid product in a small amount of chloroform, purify it with a chromatographic column, and shower it with a chloroform-methanol solution (chloroform:methanol=95:5) to obtain a single-layer yttrium phthalocyanine complex. After repeated purification and recrystallization with chloroform and n-hexane, the pure product was obtained with a yield of 45%.

[0028] Add 0.15 g of monolayer yttrium phthalocyanine complex obtained in the above steps, 0.26 g of 4,5-dioctyloxy-o-dicyanobenzene and catalyst DBU10 dropwise into 5 mL of n-pentanol, and heat to React at 150°C for 10 hours. After the product is cooled, add 50 mL of n-hexane to the reactor for recrystallization, filter the solid p...

Embodiment 2

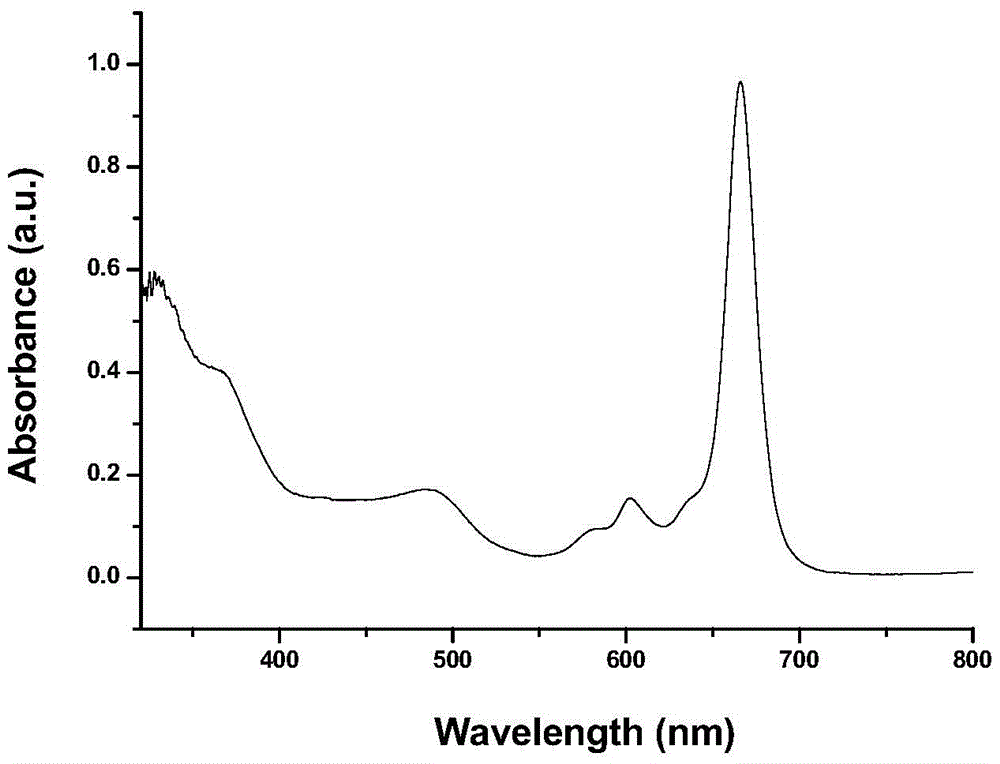

[0030] Weigh 1 g of yttrium acetylacetonate hydrate and 1.2 g of o-dicyanobenzene into a sealed reactor, add 10 mL of n-pentanol and 12 drops of catalyst DBU, and heat and stir at 100°C for 2 hours under nitrogen protection. After the product is cooled, the n-pentanol is distilled off. Dissolve the solid product in a small amount of chloroform, purify it with a chromatographic column, and shower it with a chloroform-methanol solution (chloroform:methanol=95:5) to obtain a single-layer yttrium phthalocyanine complex. After repeated purification and recrystallization with chloroform and n-hexane, the pure product was obtained with a yield of 35%.

[0031] Add 0.5 g of monolayer phthalocyanine yttrium complex obtained in the above steps, 0.9 g of 4,5-dioctyloxy-o-dicyanobenzene and catalyst DBU10 dropwise into 10 mL of n-pentanol, and heat to React at 150°C for 10 hours. After the product is cooled, add 50 mL of n-hexane to the reactor for recrystallization, filter the solid pr...

Embodiment 3

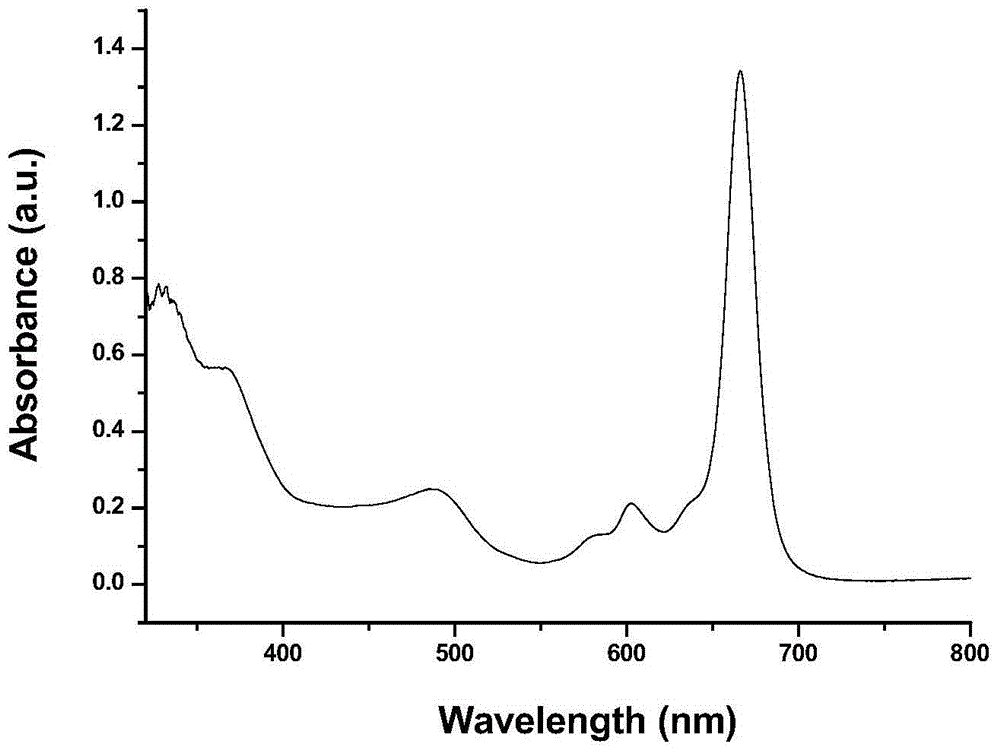

[0033] Weigh 0.46g of yttrium acetylacetonate hydrate and 0.51g of o-dicyanobenzene into a sealed reactor, add 5mL of n-pentanol and 12 drops of catalyst DBU, and heat and stir at 100°C for 4 hours under nitrogen protection. After the product is cooled, the n-pentanol is distilled off. Dissolve the solid product in a small amount of chloroform, purify it with a chromatographic column, and shower it with a chloroform-methanol solution (chloroform:methanol=95:5) to obtain a single-layer yttrium phthalocyanine complex. After repeated purification and recrystallization with chloroform and n-hexane, the pure product was obtained with a yield of 47%.

[0034] Add 0.15 g of monolayer yttrium phthalocyanine complex obtained in the above steps, 0.26 g of 4,5-dioctyloxy-o-dicyanobenzene and catalyst DBU10 dropwise into 5 mL of n-pentanol, and heat to React at 150°C for 14 hours. After the product is cooled, add 50 mL of n-hexane to the reactor for recrystallization, filter the solid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com