High-impact-resistance polyvinyl chloride pipe material

A polyvinyl chloride, high-impact technology, applied in the field of plastic processing, can solve the problems of low impact strength, high brittleness of pipes, poor crack resistance, etc., and achieve the goal of improving rigidity, increasing output, tensile strength and impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

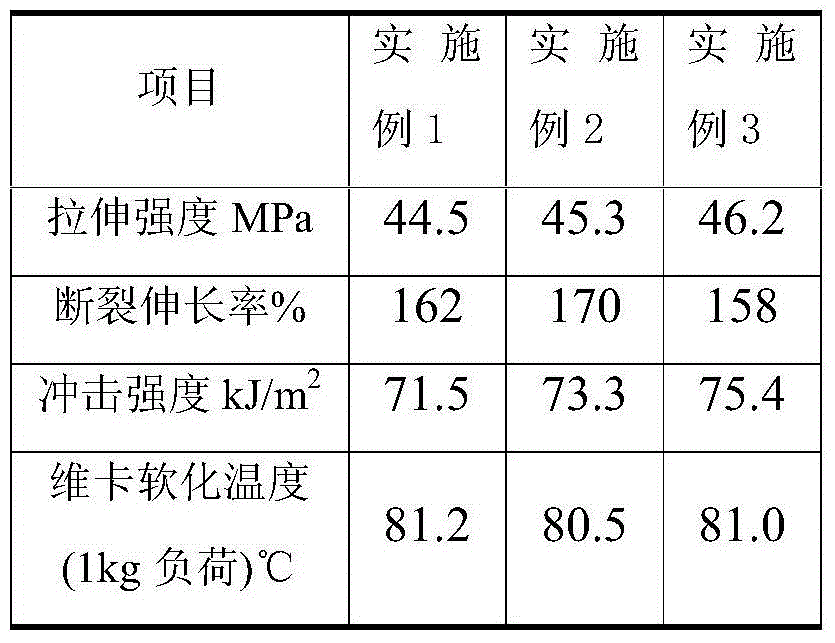

Embodiment 1

[0021] A polyvinyl chloride pipe with high impact resistance is characterized in that it consists of the following raw materials in parts by weight:

[0022] PVC resin: 80 parts;

[0023] Impact modifier: 10 parts;

[0024] Phosphite: 10 parts

[0025] Stabilizer: 5 parts;

[0026] Lubricant: 5 parts;

[0027] Light calcium carbonate: 5 parts;

[0028] Whitening agent: 2 parts.

[0029] Described lubricant is that stearic acid and PE wax are mixed in any proportion.

[0030] The stabilizer is a composite tin stabilizer.

[0031] The PVC resin is a PVC resin with a polymerization degree of 1400 to 1600.

[0032] The impact modifier is ACM-M, which is composed of a cross-linked butyl acrylate polymer as the core, a methacrylate polymer with good compatibility with PVC as the shell, and then mixed with vinyl chloride in an appropriate proportion. A polymer elastomer with a multi-layer structure or a methyl methacrylate-butadiene-styrene copolymer with a butadiene content ...

Embodiment 2

[0034] A polyvinyl chloride pipe with high impact resistance is characterized in that it consists of the following raw materials in parts by weight:

[0035] PVC resin: 80 parts;

[0036] Impact modifier: 5 parts;

[0037] Phosphites: 5 parts

[0038] Stabilizer: 0.5 parts;

[0039] Lubricant: 2 parts;

[0040] Light calcium carbonate: 1 part;

[0041] Whitening agent: 1 part.

[0042] Described lubricant is the mixture of stearic acid, paraffin and oxidized polyethylene wax.

[0043] The stabilizer is a composite tin stabilizer.

[0044] The PVC resin is a PVC resin with a polymerization degree of 1400 to 1600.

[0045] The impact modifier is ACM-M, which is composed of a cross-linked butyl acrylate polymer as the core, a methacrylate polymer with good compatibility with PVC as the shell, and then mixed with vinyl chloride in an appropriate proportion. A polymer elastomer with a multi-layer structure or a methyl methacrylate-butadiene-styrene copolymer with a butadien...

Embodiment 3

[0047] A polyvinyl chloride pipe with high impact resistance is characterized in that it consists of the following raw materials in parts by weight:

[0048] PVC resin: 80 parts;

[0049] Impact modifier: 7 parts;

[0050] Phosphites: 7 parts

[0051] Stabilizer: 3 parts;

[0052] Lubricant: 4 parts;

[0053] Light calcium carbonate: 4 parts;

[0054] Whitening agent: 1.5 parts.

[0055] Described lubricant is the mixture of stearic acid and paraffin.

[0056] The stabilizer is a composite tin stabilizer.

[0057] The PVC resin is a PVC resin with a polymerization degree of 1400 to 1600.

[0058] The impact modifier is ACM-M, which is composed of a cross-linked butyl acrylate polymer as the core, a methacrylate polymer with good compatibility with PVC as the shell, and then mixed with vinyl chloride in an appropriate proportion. A polymer elastomer with a multi-layer structure or a methyl methacrylate-butadiene-styrene copolymer with a butadiene content of more than 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com