Hydraulic power three-stage unfolding type coal bed gas cave manufacturing tool

An unfolding, coalbed methane technology, which is applied in drilling equipment, drilling equipment and methods, and earth-moving drilling and mining, etc., can solve the problems of inability to accurately obtain the diameter of the cave, the size of the hole created by mechanical tools is small, and the stability of the well wall cannot be guaranteed. , to achieve the effect of stable cave making process, stable cave making and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

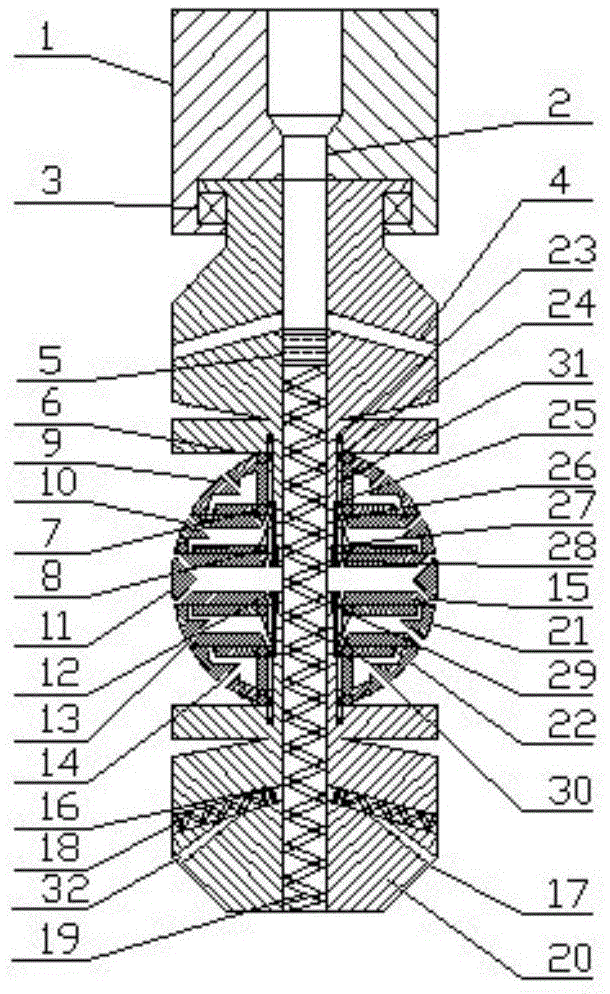

[0027] The following is attached Figure 1-17 , To further describe the present invention:

[0028] The present invention provides a hydraulic power three-stage deployment type coal-bed methane cave-making tool: it can create a cave with a diameter of 0.68 m, is simple and safe to operate, and can maintain the stability of the formation.

[0029] Tools into the ground:

[0030] The cave-making tool is connected to the drill pipe through the upper joint and descends into the destination floor. The horizontal rotation system is controlled to align with the cave-making target, and the cave-making tool is in an unexpanded state, such as figure 1 Shown.

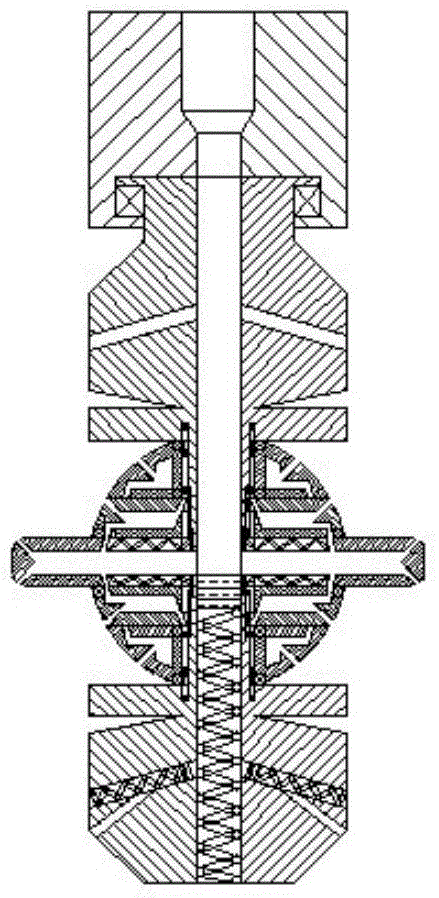

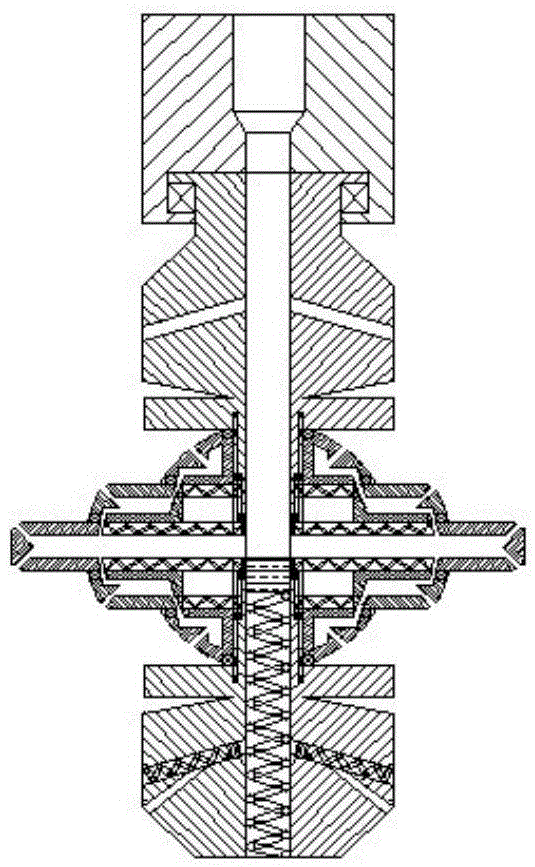

[0031] Three-level expansion process:

[0032] High-pressure fluid is introduced into the liquid flow channel 2, the spindle spring plug 5 is pushed below the horizontal liquid flow channel 12, the spindle jet channel 4 and the horizontal liquid flow channel 12 are all opened to communicate with the main liquid flow channel 2, and the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com