Contour blasting method for joint development rock masses

A profile and joint technology, which is applied in the field of profile blasting of rock mass with joints, can solve problems such as the difficulty of applying columnar joints, and achieve the effects of low material cost, improved strength and integrity, and prolonged action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

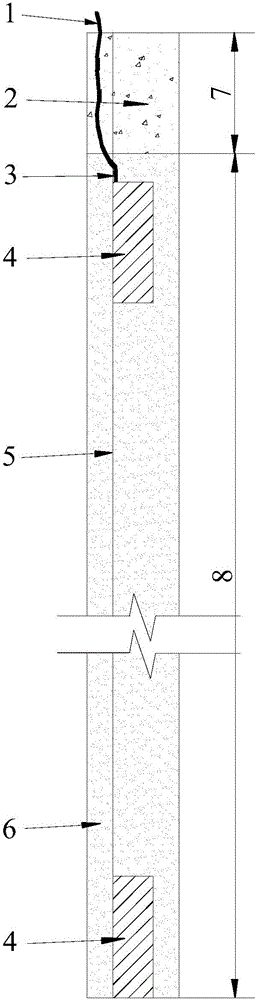

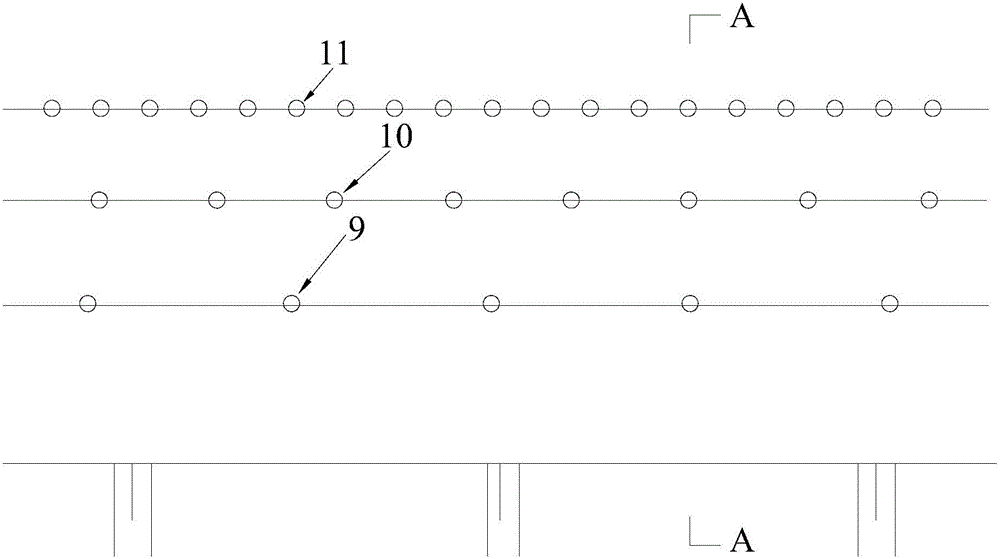

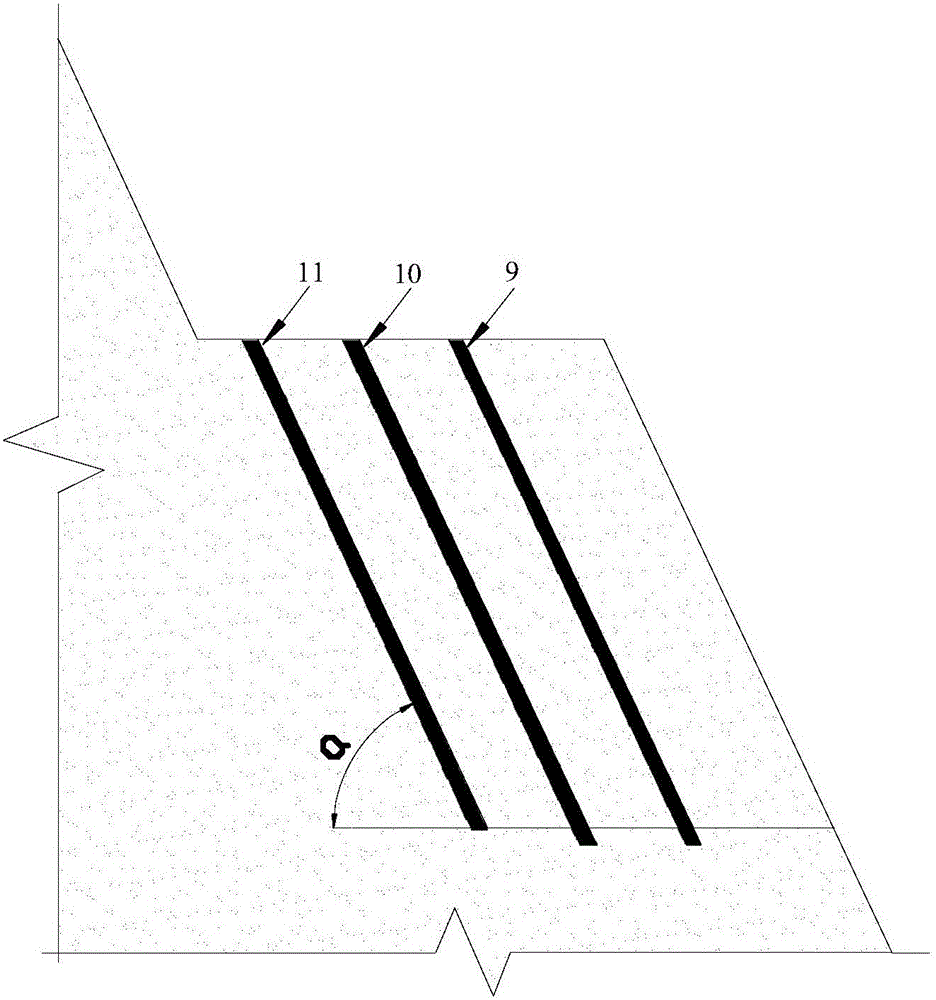

[0033] In the excavation project of the rock foundation protection layer of a high arch dam in a water conservancy and hydropower project, since the foundation rock mass belongs to columnar joint rock mass, the blasting vibration of conventional contour blasting is large, the blasting damage range is large, and the columnar joint surface loosens after blasting. Therefore, it is considered to use the contour blasting technology of the present invention to ensure the excavation quality. According to the requirements, the contour blasting method adopts the pre-splitting blasting scheme. The protective layer adopts deep hole step blasting, and the excavation and drilling layout of the protective layer is as follows: figure 2 and 3 As shown, the step height is 8m, the rock foundation inclination angle α=65o, the protective layer thickness is 5m, the drilling depth of the pre-splitting hole 11 (contour blasting hole) is 8.8m, and the main blasting hole 9 and the buffer hole 10 need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com