A Soi MOS Tube Dose Rate Radiation SPICE Macro Model Modeling Method

A technology of dose rate and macro model, applied in instrumentation, calculation, electrical and digital data processing, etc., can solve problems such as sag and peak current sag, and achieve the effect of improving simulation accuracy, efficiency and modeling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

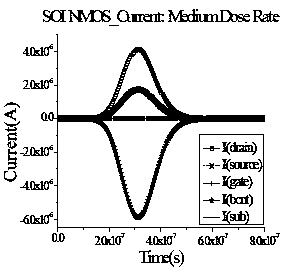

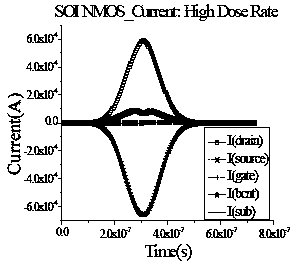

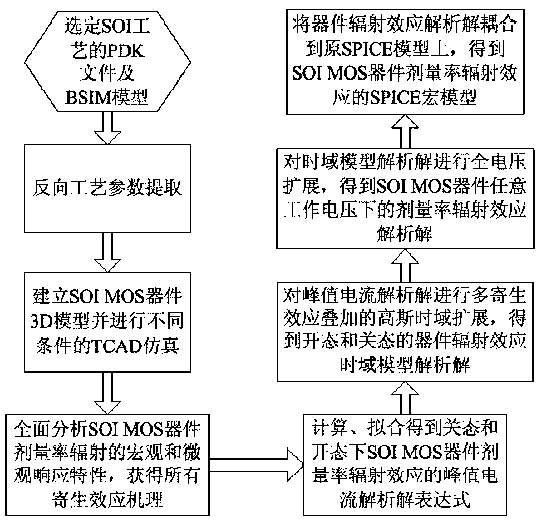

[0030] The method of the invention is suitable for MOS devices of deep submicron SOI technology, mainly including SOI technology of 0.5um, 0.35um, 0.18um, 0.15um, 0.13um and other sizes. Take the 0.5um process as an example below, combined with image 3 The flow chart shown illustrates the specific implementation process of the present invention.

[0031] First select a 0.5um SOI process line of a process manufacturer and obtain its PDK file and BSIM model, and then use Hspice (a circuit SPICE model simulator under the American Synopsys company) to simulate and obtain the parameters used for reverse process parameter extraction. standard control I D -V G curve. Then based on the known device structure, some existing process parameters (such as substrate thickness, silicon film thickness, buried oxide layer thickness, substrate uniform doping concentration, N / P well region doping depth, etc.) and various unknown parameters Establish a 3D model of the SOI MOS device and perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com