Cylindrical lithium ion power battery with high energy ratio and long service lifetime

A power battery, lithium-ion technology, applied in small-sized batteries/batteries, large-sized batteries/batteries, secondary batteries, etc., can solve the problems of large internal resistance, low capacity, and large number of batteries, etc. Achieve the effect of improving production efficiency, reducing processing difficulty, and optimizing riveting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

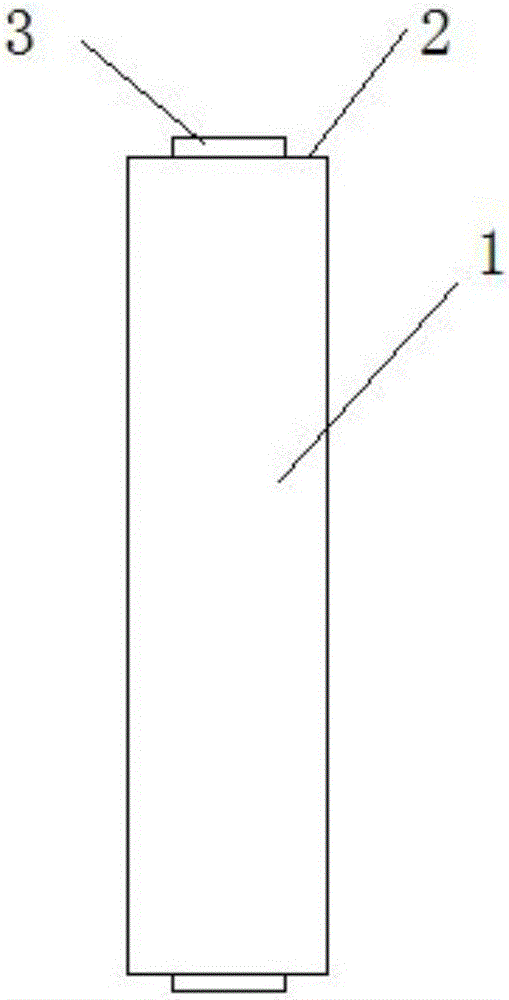

[0016] like Figure 1-4 As shown, a high-energy-ratio, long-life cylindrical lithium-ion power battery of this embodiment, the aspect ratio of the cylindrical lithium-ion power battery is 3.8-4.2. Preferably, the diameter of the cylindrical lithium-ion power battery is 32 mm, the height is 131 mm, the size of the battery is relatively large, and the capacity of the single battery is high, which makes use of the characteristics of high energy ratio of the cylinder.

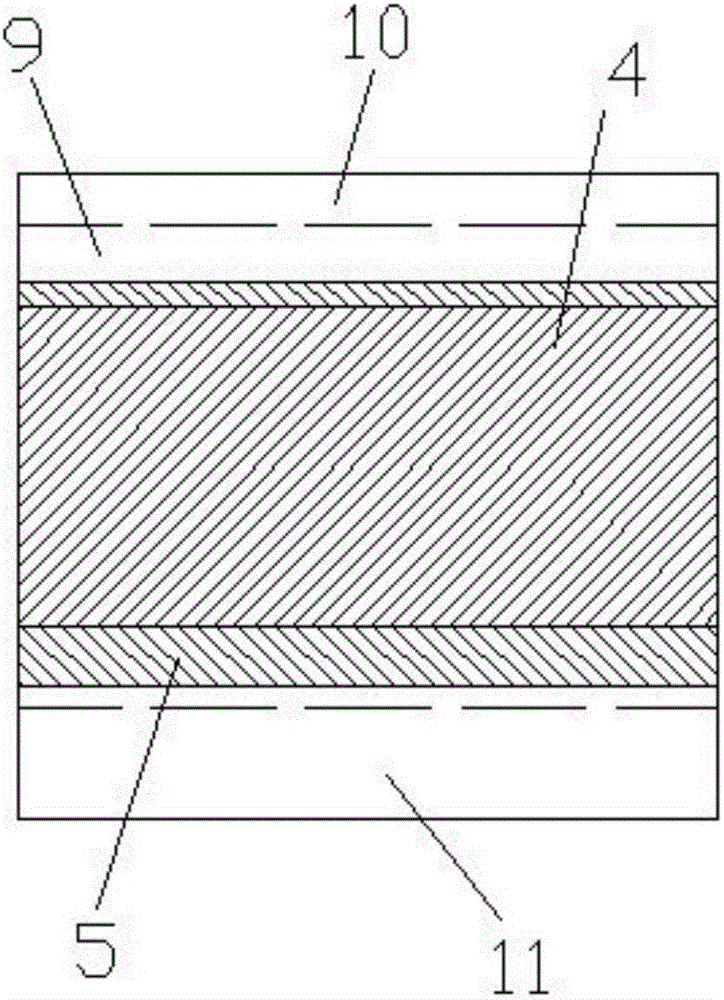

[0017] The cell of the cylindrical lithium-ion power battery includes the positive electrode coating 4 and the positive electrode tab 10, the negative electrode coating 5 and the negative electrode tab 11, and the separator 9 between the positive and negative electrodes. The negative electrode coating 5 is wider than the positive electrode coating 4 and is asymmetrically coated. Hold the positive electrode paint 4, the distance of the negative electrode paint 5 beyond the front end of the positive electrode paint 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com