A kind of silicone rubber heater and its manufacturing process

A manufacturing process and heater technology, applied in the direction of ohmic resistance heating, heating element materials, sustainable manufacturing/processing, etc., can solve the problems of limited use time, surface shedding, leakage and heat insulation effects, etc., to prevent thread ends from falling off, Improves lifespan and prevents rapid aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

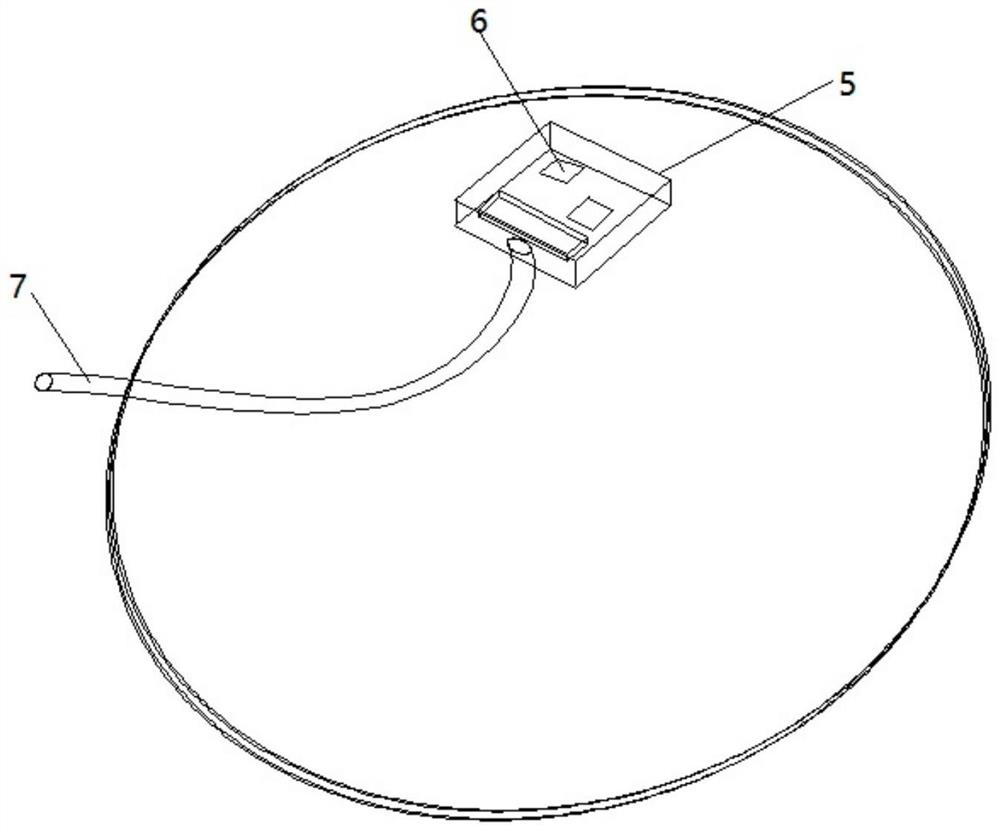

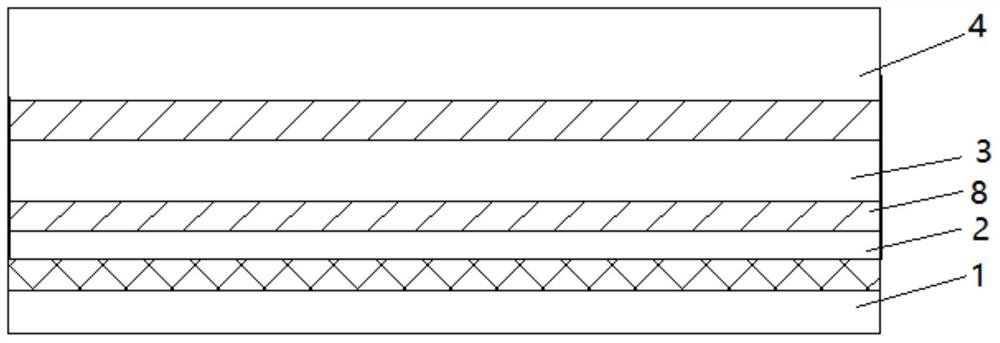

[0033] Such as figure 1 and figure 2 The silicone rubber heater includes: a silicone rubber layer 1, a thermal insulation layer 2, a heating core 3, a heating body 4, a power supply box 5, a temperature controller 6, a power lead wire 7 and an adhesive tape 8, and the described An insulating layer is arranged on the heat insulating layer 2 .

[0034] The relationship between the above components is as follows:

[0035] The heating core 3 is made of high-combination gold wire or metal foil, the silicone rubber layer 1 is arranged on the outside of the heat insulation layer 2, the heating core 3 is arranged on the heat insulation layer 2, and its Adhesive tapes 8 are arranged on the upper and lower surfaces, the heating body 4 is arranged above the heating core 3, the power supply box 5 is arranged above the silicone rubber layer 1, and the temperature controller 6 and the power lead-out wires are connected with the Terminal connections inside the power supply box 5.

[003...

Embodiment 2

[0041] The structure of the silicone rubber heater described in this embodiment is the same as that in Embodiment 1.

[0042] A manufacturing process of a silicone rubber heater, the specific manufacturing process is as follows:

[0043] (1): First, prepare the material according to the needs of the heater, and start processing after the material is ready;

[0044] (2): First spread the prepared silicone rubber layer 1, and then place the insulating layer on the surface of the silicone rubber layer 1;

[0045] (3): After the insulation layer is set, the heat insulation layer 2 is placed above the insulation layer;

[0046] (4): After the heat insulation layer 2 is laid, remove the adhesive tape 8 on the back of the heating core 3 and stick it on the top of the heat insulation layer 2;

[0047] (5): Then remove the adhesive tape on the front of the adhesive tape 8 on the upper surface of the heating core 3, and paste the heating element 4 on the removed adhesive tape 8;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com