Reinforcing fiber fabric substrate, preform, and fiber-reinforced composite material

A technology for reinforcing fibers and prefabricated parts, applied in the field of prefabricated parts and fiber-reinforced composite materials, can solve problems such as low adhesion, and achieve the effect of improving designability and excellent matrix resin impregnation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

[0183]

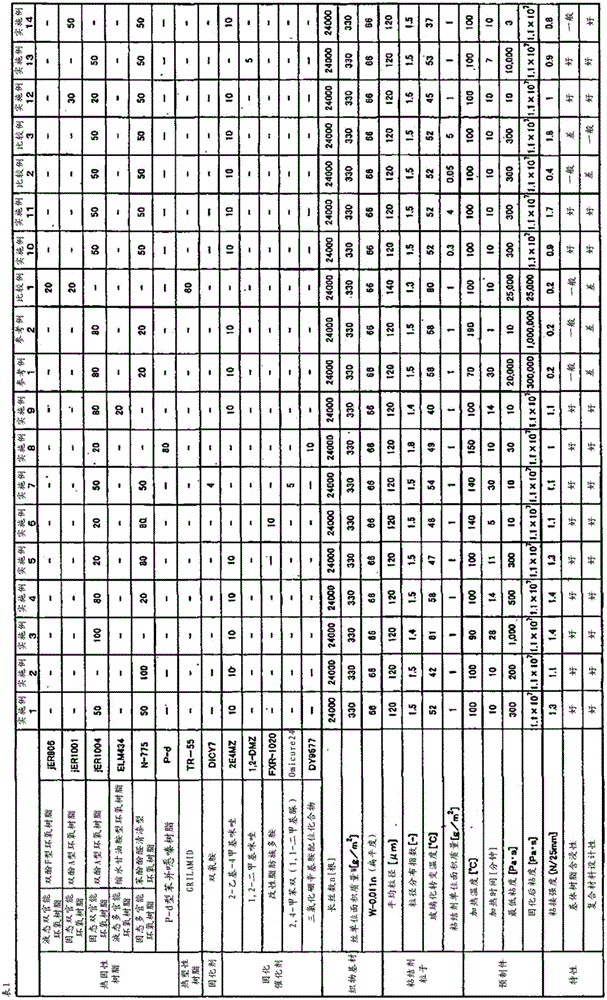

[0184] Based on the compounding ratio in Table 1, using the binder particles prepared as described above, the minimum viscosity was measured as described above under the heating conditions shown in Table 1. In addition, using the reinforcing fiber fabric base material shown in Table 1 dispersed with the binder particles, the preforms for the evaluation of the adhesive strength and the preforms for the evaluation of the matrix resin impregnation property were respectively produced as described above under the heating conditions shown in Table 1. pieces. The evaluation of the adhesive strength and the impregnation property of the liquid matrix resin were performed on each of the produced preforms. Then, the surface quality of the fiber-reinforced composite material molded to evaluate the impregnation property of the liquid matrix resin was evaluated as described above.

Embodiment 1

[0185] In Example 1, as shown in Table 1, the binder particles and the reinforcing fiber fabric are used to form a binder with a mass per unit area of 1 g / m 2 The reinforced fiber fabric base material combined in the above method was molded at a heating temperature of 100°C and a heating time of 10 minutes, thereby producing preforms and fiber-reinforced composite materials. The preform produced under this condition obtains excellent bonding strength, and the impregnation of the matrix resin and the surface design of the molded body are also excellent, wherein the above-mentioned binder particles are composed of solid bifunctional epoxy resin and solid multifunctional epoxy resin, Composed of imidazole curing catalyst, the particle size is 120 μm, the particle size distribution index is 1.5, the number of filaments of the above-mentioned reinforced fiber fabric is 24,000, and the mass per unit area of the filament is 330g / m 2 .

Embodiment 2

[0186] In Example 2, as shown in Table 1, all the thermosetting resin components constituting the binder particles were solid multifunctional epoxy resins, and each preform and fiber-reinforced composite material were produced under the same conditions as in Example 1, and carried out. its evaluation. Since the crosslinking density of the binder after heating and curing becomes higher, the adhesive strength decreases, but sufficient adhesive strength is obtained, and the impregnation of the matrix resin and the surface design of the molded article are also excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com