Puffed black fungus powder and preparation method thereof

A technology of fungus powder and fungus, which is applied in the field of food processing, can solve the problems of reducing the absorption rate of black fungus nutrients, etc., and achieve the effects of improving drug efficacy and bioavailability, improving absorption, and excellent nutritional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment one: a kind of puffed fungus powder, described fungus powder is made through the following steps,

[0027] a: Wash the fungus and smash it into small pieces;

[0028] b: Dry the fungus at a temperature of 60°C for 50 minutes so that the water content is 8%;

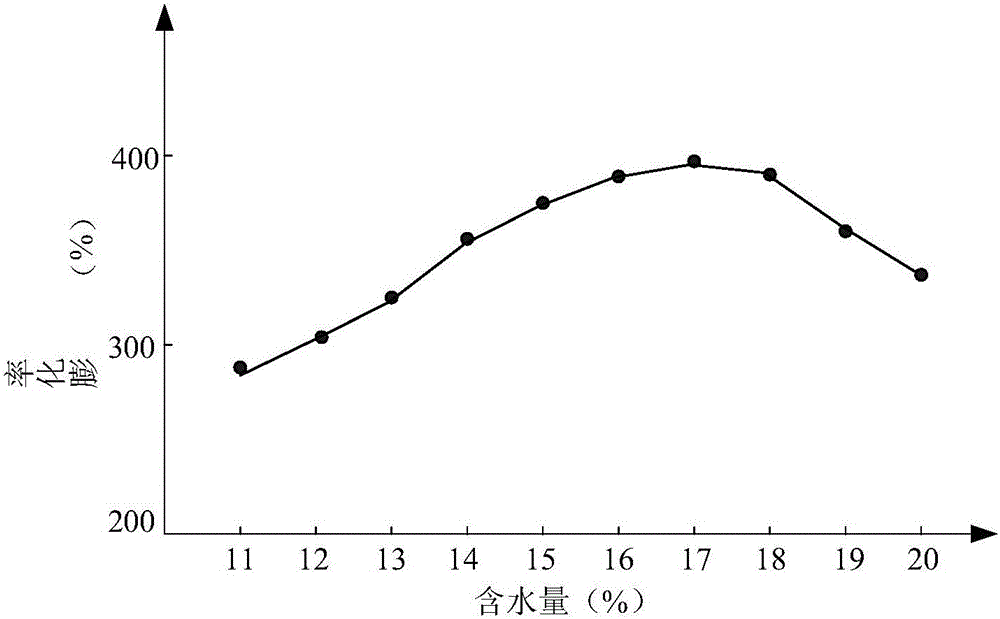

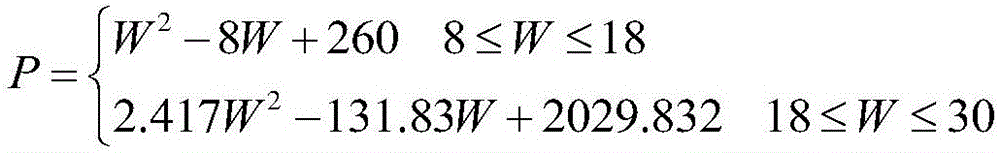

[0029] c: Carry out vacuum microwave puffing treatment on fungus, microwave power 650W, puffing time 5min, vacuum degree 0.05MPa, puffing rate 295%;

[0030] d: sending the puffed fungus into a pulverizer for 100-mesh crushing to obtain fungus powder.

Embodiment 2

[0031] Embodiment two: a kind of puffed fungus powder, described fungus powder is made through the following steps,

[0032] a: Wash the fungus and smash it into small pieces;

[0033] b: Dry the fungus at a temperature of 50°C for 40 minutes so that the water content is 17%;

[0034] c: Carry out vacuum microwave puffing treatment on fungus, microwave power 750W, puffing time 8min, vacuum degree 0.08MPa, puffing rate 398%;

[0035] d: sending the puffed fungus into a pulverizer for 100-mesh crushing to obtain fungus powder.

Embodiment 3

[0036] Embodiment three: a kind of puffed fungus powder, described fungus powder is made through the following steps,

[0037] a: Wash the fungus and smash it into small pieces;

[0038] b: Dry the fungus at a temperature of 40°C for 30 minutes to make the water content 30%;

[0039] c: Carry out vacuum microwave puffing treatment on fungus, microwave power 780W, puffing time 12min, vacuum degree 0.10MPa, puffing rate 280%;

[0040] d: sending the puffed fungus into a pulverizer for 100-mesh crushing to obtain fungus powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com