Permanent magnet sampling detection pharmaceutical device

A permanent magnet and filling technology, which is applied in the direction of making medicines into special physical or taking forms of devices, etc., can solve the problems of high temperature in the upper half, low production efficiency, affecting product quality, etc., to improve the balance, High production efficiency and good disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

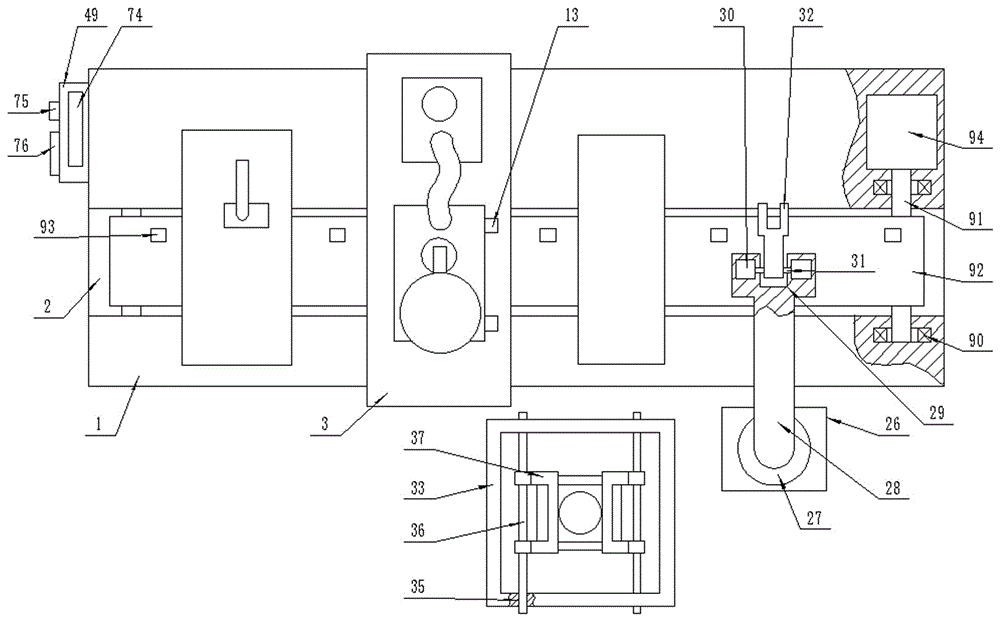

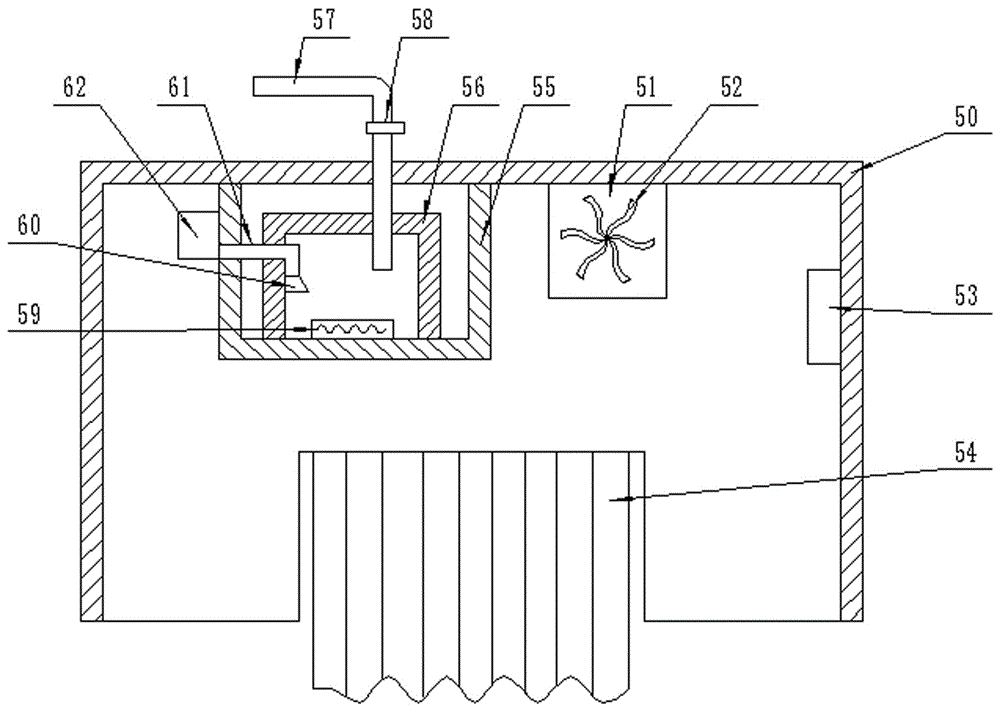

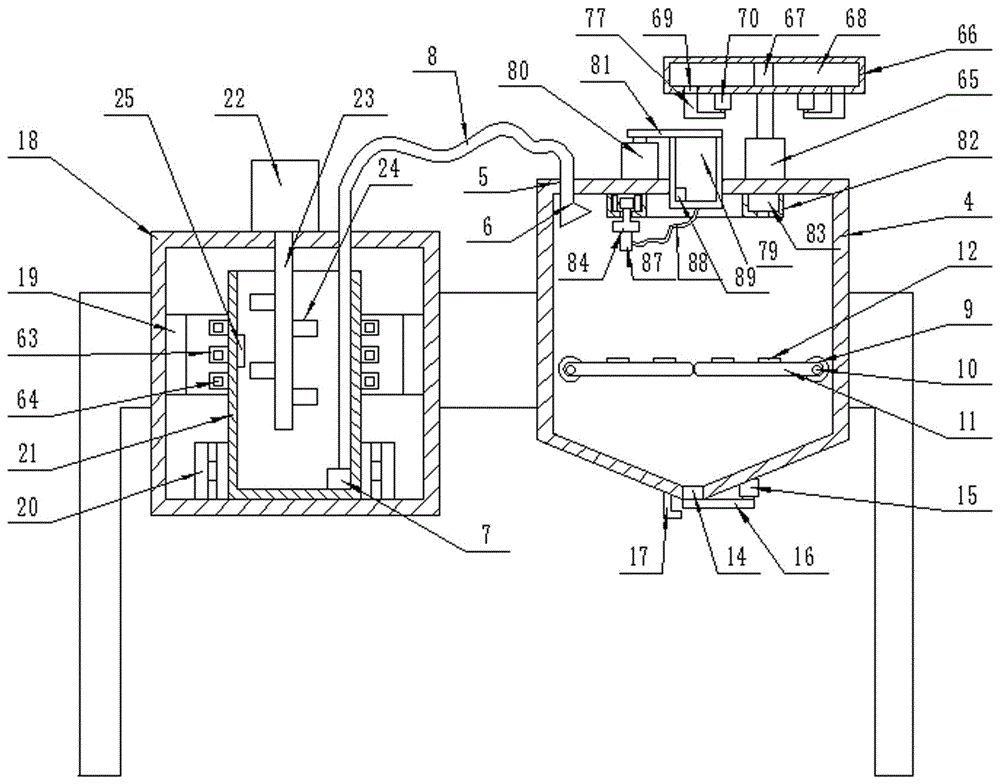

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a permanent magnet sampling and testing pharmaceutical device includes a base (1), the upper surface of the base (1) is provided with a through groove (2) along its length direction, and the through groove (2) is equipped with There is a transmission mechanism, and the upper surface of the base (1) is sequentially provided with a steam disinfection mechanism, a drop pill filling mechanism, a bottle cap hot-press sealing mechanism, and a drug sampling device along its length direction, and the drop pill filling mechanism consists of The bottom is fixedly installed on the frame (3) on the ground on both sides of the base (1), the pharmaceutical box (4) fixedly embedded in the frame (3), and the round hole A ( 5), the pharmaceutical grain nozzle (6) fixedly embedded in the round hole A (5), the connecting pipe (8) that is fixedly connected to the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com