A high-efficiency continuous crack-free flattening method for bamboo

A continuous, crack-free technology, applied in the direction of mechanical equipment, sugarcane machining, etc., can solve the problem of high compressive strength of pressure tanks, and achieve the effect of reducing strength, reducing harsh environment, reducing quality and aesthetic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

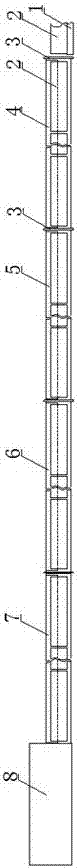

[0026] Embodiment 1, as shown in the accompanying drawing

[0027] The high-efficiency continuous non-crack flattening method of bamboo tubes comprises the following process steps:

[0028] Step (1) Pre-treat the fresh bamboo tubes; after 6 days of cutting, the bamboo tubes are cut off as required, and then through a combination of equipment, the inner nodes, green bamboo and outer nodes are removed at the same time, and then a 4mm wide vertical straight line sawing slit is cut on the bamboo tubes .

[0029] Step (2) Put the bamboo tube into the heating pipeline for heat treatment, put the saw kerf of the bamboo tube up, and align it with the positioning device on the slideway, put it on the slideway, and the bamboo tube enters the pipeline preheating chamber A, preheating chamber B, high temperature In the steam heating room and the heat preservation room, the corresponding temperatures are 40°C, 60°C, 130°C and 100°C respectively. By controlling the partition doors in the m...

Embodiment 2

[0032] Embodiment 2, as shown in the accompanying drawing, the efficient continuous non-crack flattening method of bamboo tube comprises following processing steps:

[0033] Step (1) Pre-treat fresh bamboo tubes; after 8 days of felling, the bamboo tubes are cut off as required, and then through a combined device, the inner nodes, green bamboo and outer nodes are removed at the same time, and then a 5mm-width vertical straight-line sawing kerf is cut on the bamboo tubes .

[0034] Step (2) Put the bamboo tube into the heating pipeline for heat treatment, put the saw kerf of the bamboo tube up, and align it with the positioning device on the slideway, put it on the slideway, and the bamboo tube enters the pipeline preheating chamber A, preheating chamber B, high temperature In the steam heating room and the heat preservation room, the corresponding temperatures are 80°C, 100°C, 160°C and 120°C respectively. By controlling the partition doors in the middle of the heating pipe, t...

Embodiment 3

[0037] Embodiment 3, as shown in the accompanying drawing, the efficient continuous non-crack flattening method of bamboo tube comprises following processing steps:

[0038] Step (1) Pre-treat fresh bamboo tubes; after 8 days of felling, the bamboo tubes are cut off as required, and then through a combination of equipment, the inner nodes, bamboo green and outer nodes are removed at the same time, and then a 6mm wide vertical straight line sawing slit is cut on the bamboo tubes .

[0039] Step (2) Put the bamboo tube into the heating pipeline for heat treatment, put the saw kerf of the bamboo tube up, and align it with the positioning device on the slideway, put it on the slideway, and the bamboo tube enters the pipeline preheating chamber A, preheating chamber B, high temperature In the steam heating room and the heat preservation room, the corresponding temperatures are 60°C, 80°C, 145°C and 110°C respectively. By controlling the partition doors in the middle of the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com