A material transfer method in the production process of a venous compounding room

A production process and material transmission technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve problems such as difficulty in clarifying job responsibilities, increasing operator workload, and difficulty in responsibility tracking, achieving perfect responsibility tracking. System, small footprint, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

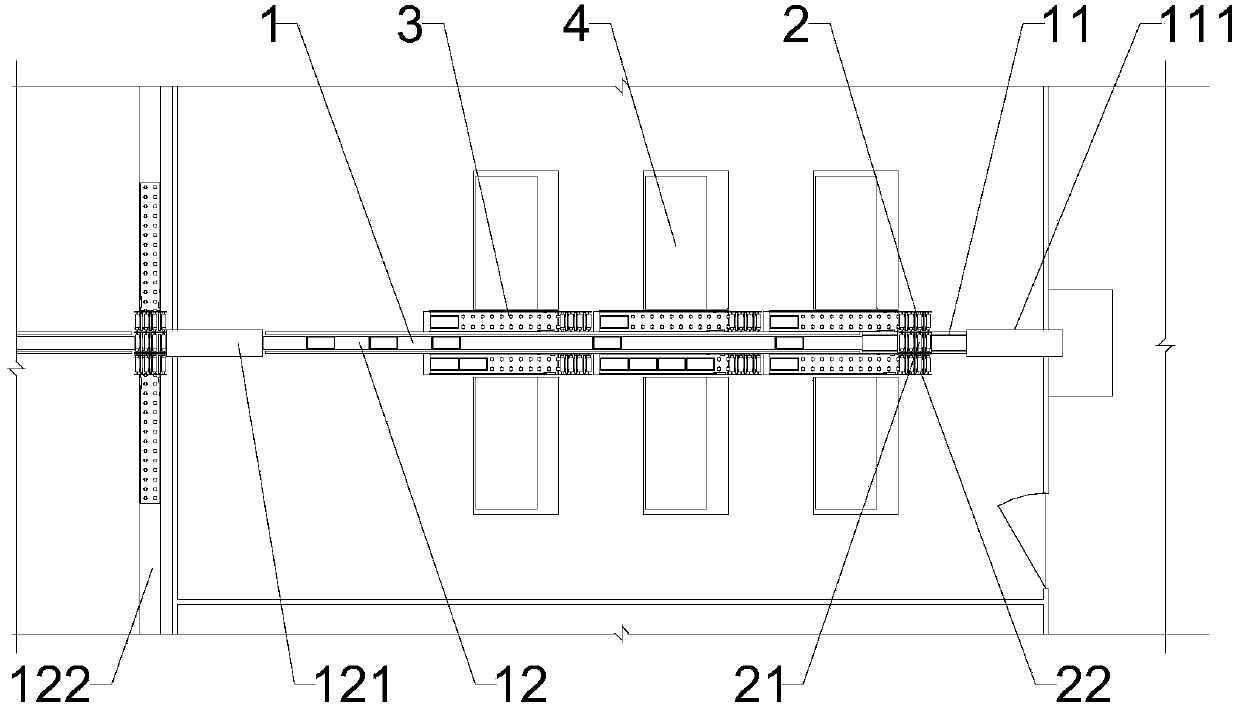

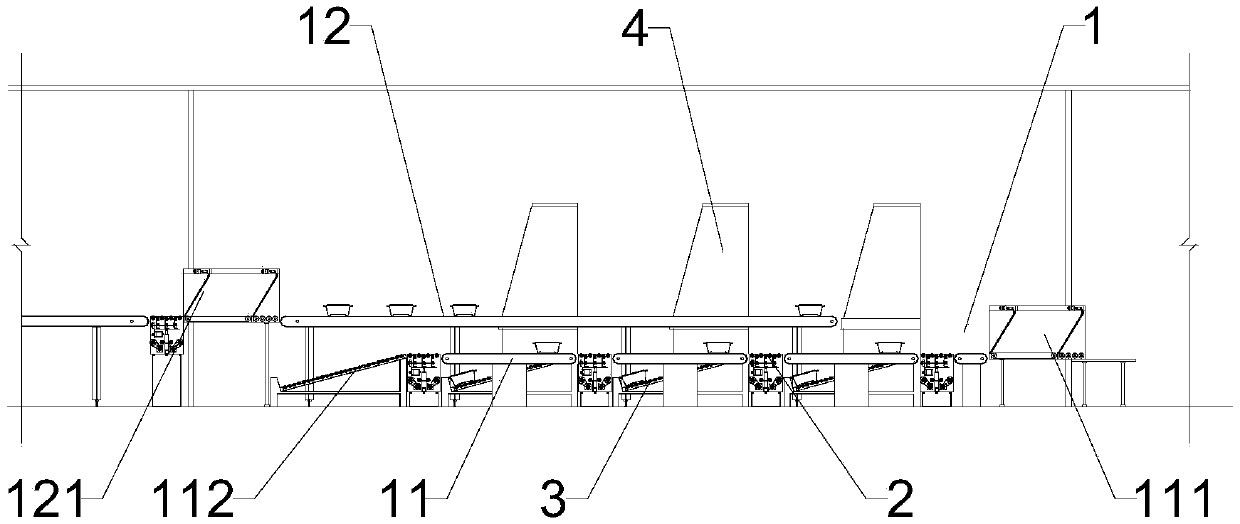

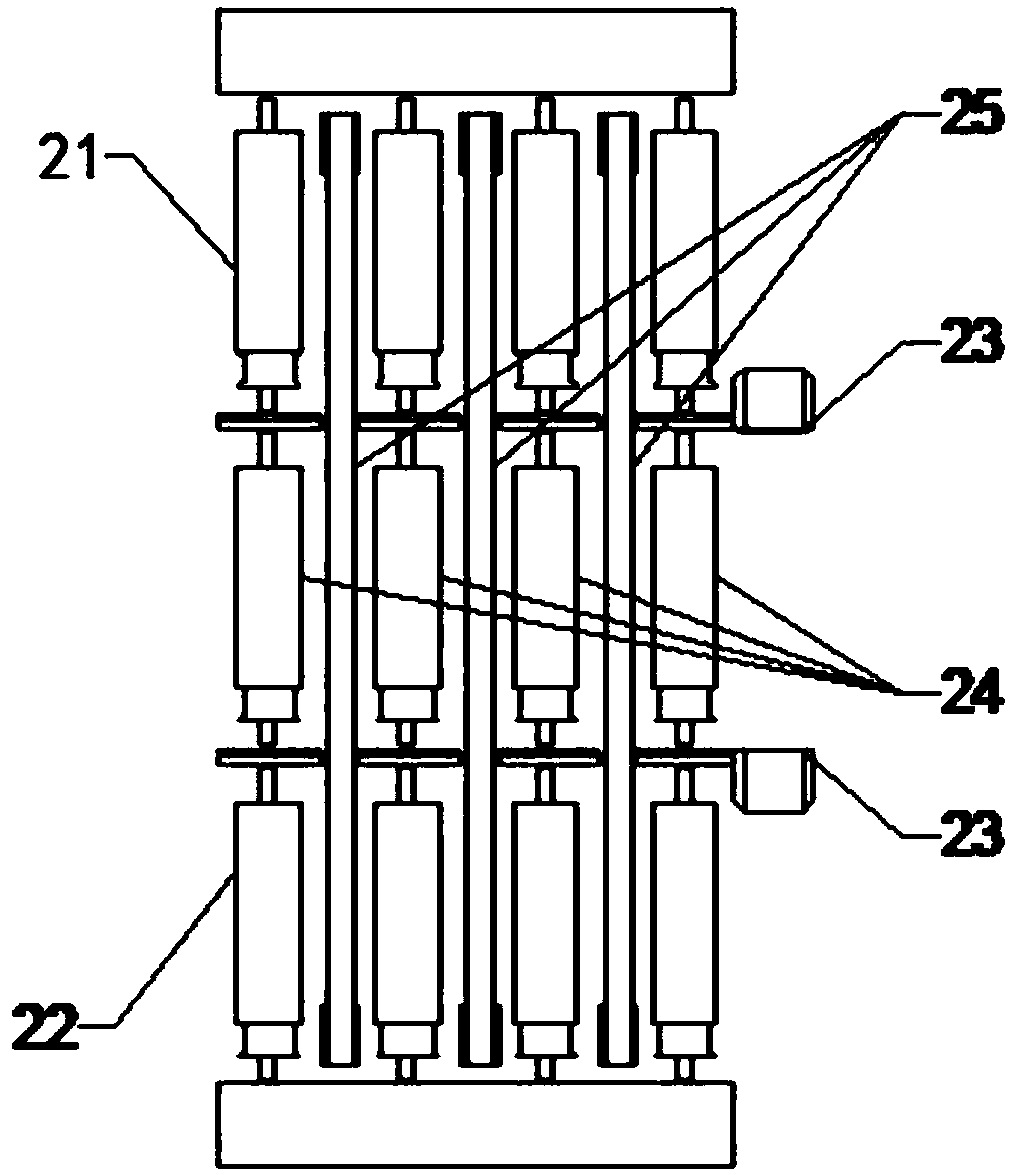

[0037] The material transfer method in the production process of the intravenous compounding room described in the embodiment of the present invention consists of the following steps:

[0038] (1) Number the indoor staff, outdoor staff, workbench and material basket respectively;

[0039] (2) When the indoor staff arrive at the workbench to prepare for work, they first use the code reader to read and write the job number and the workbench number, and send them to the information management platform, which automatically generates a station identification code;

[0040] (3) Outdoor staff print the list of materials, and pick out the required materials according to the list and put them into the basket, and paste the list on the designated position of the basket. At the same time, use the code reader to read and write the list and the number of the basket, and send it To the information management platform, the platform automatically generates a loading basket identification code...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com