Iridescent joint filling plaster

A technology of caulking paste and magic color, applied in the field of caulking paste, can solve the problems of affecting the appearance, easy oxidation and blackening, loss of decorative effect, etc., and achieve the effect of improving decorative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

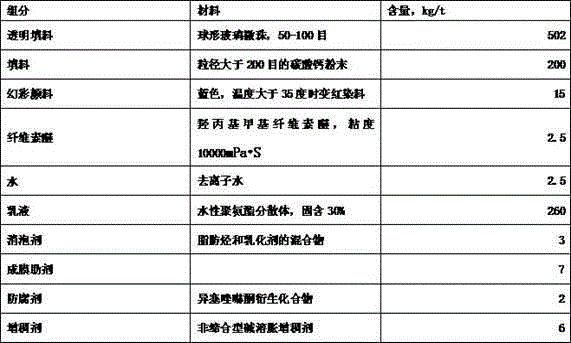

Embodiment 1

[0034] Example 1: What is obtained is a translucent frosted glass-like surface, which turns light blue under ultraviolet light / sunlight.

[0035]

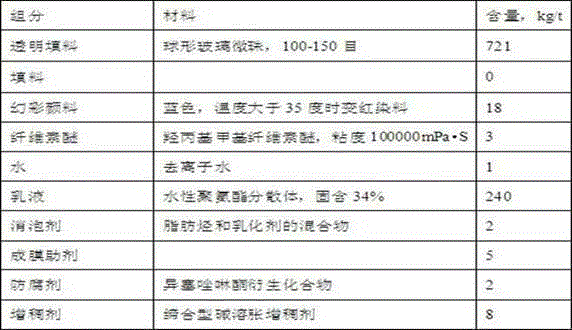

Embodiment 2

[0036] Example 2: What is obtained is a transparent, colorless, rough and grainy surface, which turns pink under ultraviolet light / sunlight irradiation.

[0037]

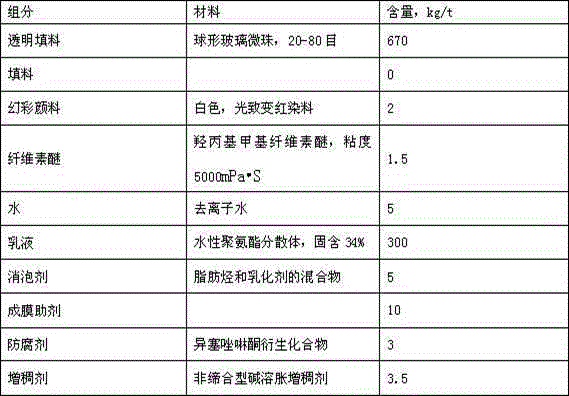

Embodiment 3

[0038] Embodiment 3: What is obtained is a translucent blue hazy surface, which turns pink when the ambient temperature is greater than 35 degrees.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com