Thermal sensitive ceramic material with low electrical resistivity and negative temperature coefficient and preparation method thereof

A negative temperature coefficient, low resistivity technology, applied in the field of ceramic materials, can solve the problems of reducing resistivity, low resistivity, reducing B value, etc., to achieve the effect of reducing porosity, small resistivity, and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

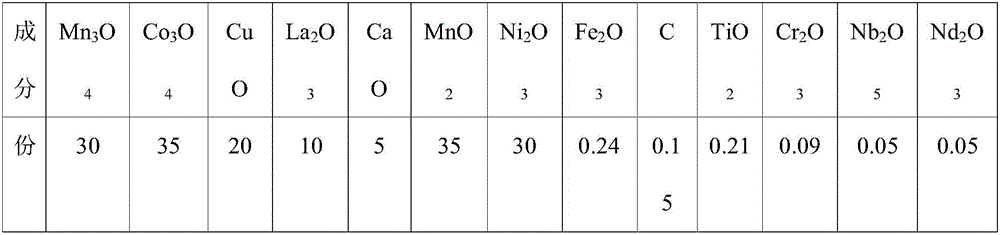

Embodiment 1

[0023] A thermosensitive ceramic material with a low negative temperature coefficient of resistivity, the raw materials according to parts by weight include: Mn 3 o 4 : 30 copies, Co 3 o 4 : 35 parts, CuO: 20 parts, La 2 o 3 : 10 parts, CaO: 5 parts, MnO 2 : 35 parts, Ni 2 o 3 : 30 parts, Fe 2 o 3 : 0.24 parts, C: 0.15 parts, TiO 2 : 0.21 parts, Cr 2 o 3 : 0.09 parts, Nb 2 o 5 : 0.05 parts, Nd 2 o 3 : 0.05 parts.

[0024] The preparation method of the heat-sensitive ceramic material with a negative temperature coefficient of low resistivity, the specific steps are as follows:

[0025] (1) Firstly, La 2 o 3 , CaO, MnO 2 、Ni 2 o 3 As a raw material, it was weighed according to the atomic percentage of the perovskite phase LaCaMnO and the atomic percentage of the spinel phase NiMnO, respectively, and placed in an agate ball mill jar, and water was used as the dispersion medium for wet grinding for 8 hours to obtain the first ball mill ;

[0026] (2) Fe 2 o...

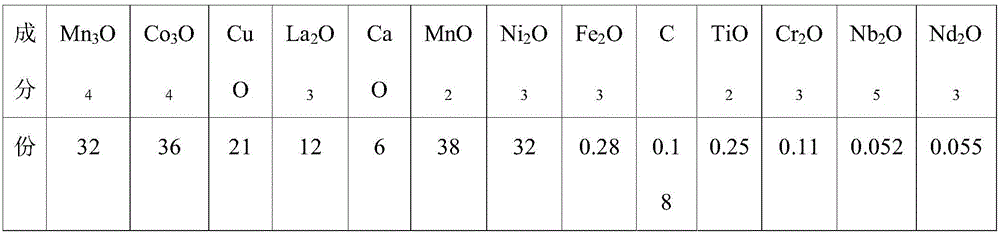

Embodiment 2

[0042] A thermosensitive ceramic material with a low negative temperature coefficient of resistivity, the raw materials according to parts by weight include: Mn 3 o 4 : 32 copies, Co 3 o 4 : 36 parts, CuO: 21 parts, La 2 o 3 : 12 parts, CaO: 6 parts, MnO 2 : 38 copies, Ni 2 o 3 : 32 parts, Fe 2 o 3 : 0.28 parts, C: 0.18 parts, TiO 2 : 0.25 parts, Cr 2 o 3 : 0.11 parts, Nb 2 o 5 : 0.052 parts, Nd 2 o 3 : 0.055 parts.

[0043] The preparation method of the heat-sensitive ceramic material with a negative temperature coefficient of low resistivity, the specific steps are as follows:

[0044] (1) Firstly, La 2 o 3 , CaO, MnO 2 、Ni 2 o 3 As a raw material, it was weighed according to the atomic percentage of the perovskite phase LaCaMnO and the atomic percentage of the spinel phase NiMnO, respectively, and placed in an agate ball mill jar, and water was used as the dispersion medium for wet grinding for 8 hours to obtain the first ball mill ;

[0045] (2) Fe ...

Embodiment 3

[0062] A thermosensitive ceramic material with a low negative temperature coefficient of resistivity, the raw materials according to parts by weight include: Mn 3 o 4 : 35 copies, Co 3 o 4 : 38 parts, CuO: 22 parts, La 2 o 3 : 15 parts, CaO: 8 parts, MnO 2 : 40 parts, Ni 2 o 3 : 35 parts, Fe 2 o 3 : 0.32 parts, C: 0.2 parts, TiO 2 : 0.28 parts, Cr 2 o 3 : 0.12 parts, Nb 2 o 5 : 0.055 parts, Nd 2 o 3 : 0.06 parts.

[0063] The preparation method of the heat-sensitive ceramic material with a negative temperature coefficient of low resistivity, the specific steps are as follows:

[0064] (1) Firstly, La 2 o 3 , CaO, MnO 2 、Ni 2 o 3 As a raw material, it was weighed according to the atomic percentage of the perovskite phase LaCaMnO and the atomic percentage of the spinel phase NiMnO, respectively, and placed in an agate ball mill jar, and water was used as the dispersion medium for wet grinding for 8 hours to obtain the first ball mill ;

[0065] (2) Fe 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com