Preparation method of s-triazine compound

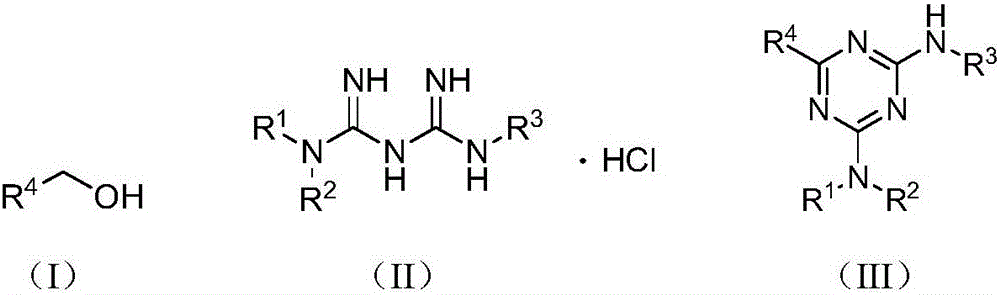

A compound, the technology of s-triazine, which is applied in the field of preparation of s-triazine compounds, achieves the effects of low cost, wide industrial application prospect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

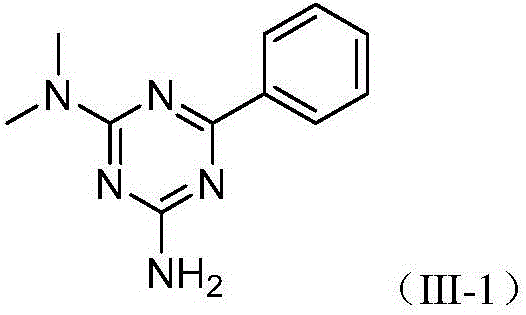

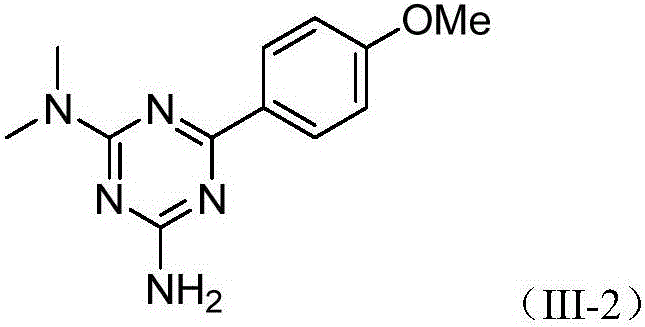

[0018] The present invention will be further described below through specific examples, but the protection scope of the present invention is not limited thereto. Embodiment 1: the preparation of compound (III-1)

[0019] In a reaction vessel, add metformin hydrochloride (0.1653g, 0.9954mmol), benzyl alcohol (0.1082g, 1.0002mmol), 1,5-cyclooctadiene ruthenium dichloride (0.0056g, 0.02mmol), tert-butyl Potassium alcoholate (0.2250g, 2.0052mmol), 1,4-dioxane (4mL), stirred and reacted in an oil bath at 100°C for 15 hours; after the reaction, add water (10mL), extract with ethyl acetate (10mL× 3), the organic layers were combined, dried with anhydrous sodium sulfate, filtered, and the filtrate was concentrated, and the obtained concentrate was separated by column chromatography, and the eluent was dichloromethane:methanol=50:1 (V:V), and R f The eluate with a value of 0.3-0.35 (monitored by TLC, the developing solvent is the same as the eluent) was distilled under reduced pressur...

Embodiment 2

[0023] Change 1,5-cyclooctadiene ruthenium dichloride to dodecacarbonyl ruthenium (0.0128g, 0.02mmol), other operations are the same as in Example 1, and finally obtain the target compound (III-1) 0.1586g, the yield is 74 %.

Embodiment 3

[0025] 1,5-Cyclooctadiene ruthenium dichloride was changed to triphenylphosphine ruthenium chloride (0.0182g, 0.02mmol), and other operations were the same as in Example 1 to finally obtain 0.1180g of the target compound (III-1). The rate is 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com