Magnesium alloy cutting liquid and preparation method thereof

A magnesium alloy and cutting fluid technology, which is applied in the field of magnesium alloy cutting fluid and its preparation, can solve the problems of precipitation on machine tool guide rails, worktables, etc., and achieve the effects of efficient control of corrosion and discoloration, and high-strength resistance to hard water.

Inactive Publication Date: 2016-07-13

安徽华灿润滑技术有限公司

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the current existing technology, magnesium alloy cutting fluid has three major technical difficulties: one is that its material is quite active, and it must be prevented from being corroded by water during and after processing; the other is that magnesium alloy is prone to produce powder during processing. Magnesium hydroxide precipitates on the guide rails and work surfaces of machine tools; third, magnesium alloys are continuously dissolved into the cutting fluid, and the hardness of the cutting fluid will gradually increase, so the cutting fluid must have a very high resistance to hard water, so that the cutting fluid is not easy to appear demulsification and delamination

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

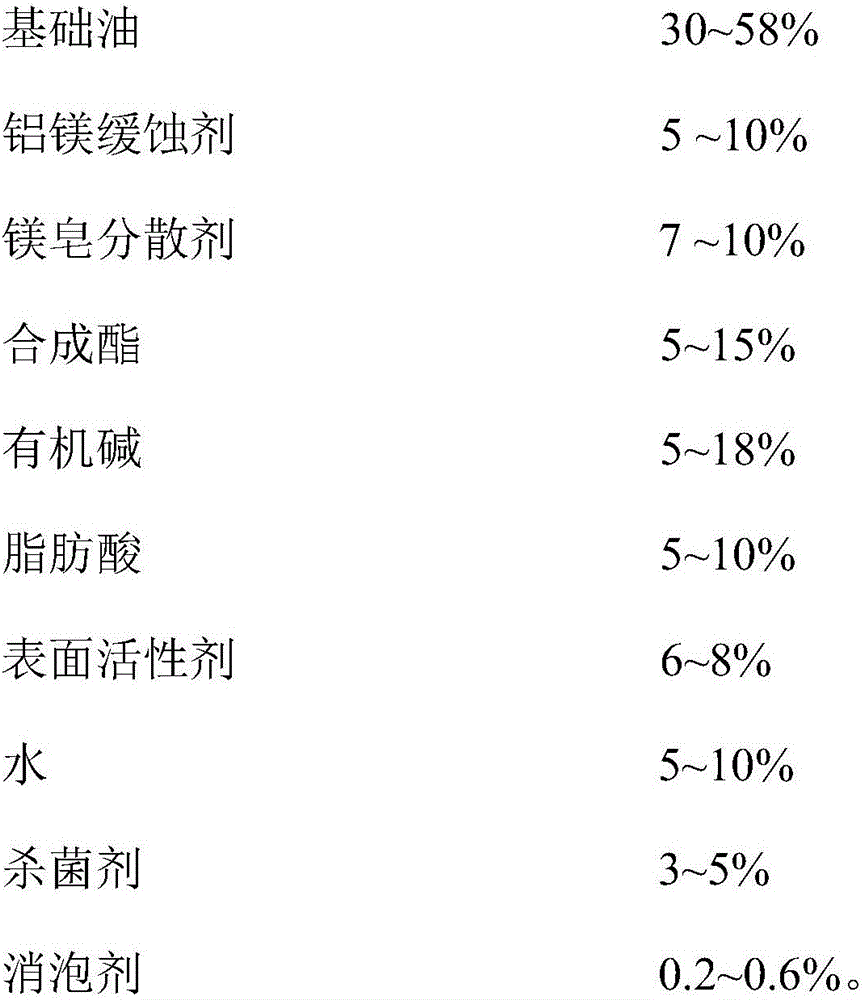

[0023] A kind of magnesium alloy cutting fluid, comprises the raw material of following percentage by weight:

[0024]

[0025]

Embodiment 2

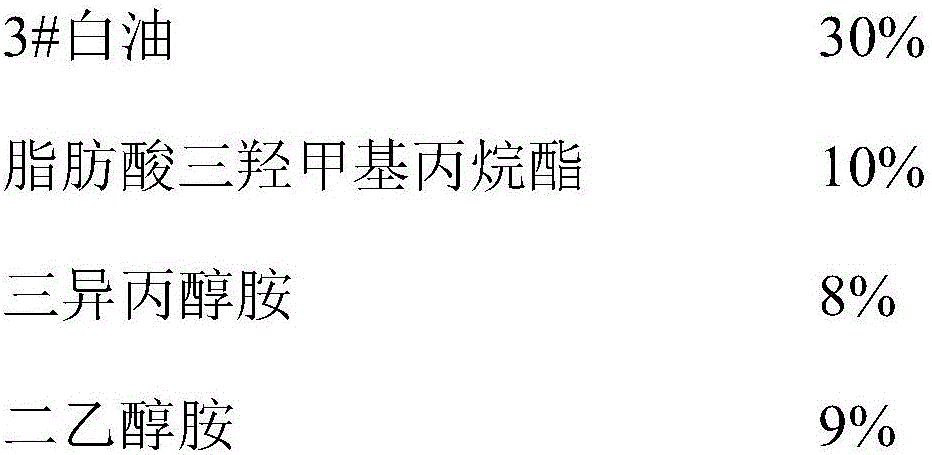

[0027] A kind of magnesium alloy cutting fluid, comprises the raw material of following percentage by weight:

[0028]

[0029]

Embodiment 3

[0031] A kind of magnesium alloy cutting fluid, comprises the raw material of following percentage by weight:

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses magnesium alloy cutting liquid and a preparation method thereof.Compared with the prior art, the magnesium alloy cutting liquid has high-strength hard water resisting performance, the highest magnesium hard water resistance can reach 6,000 pm, the service life of the cutting liquid is effectively prolonged, great assistance in environmental protection and energy saving advocated in the country is achieved, a liquid tank does not need to be replaced after being used for 6 month to the longest on site, and the magnesium alloy cutting liquid is environmentally friendly.

Description

technical field [0001] The invention belongs to the field of cutting fluid, and in particular relates to a magnesium alloy cutting fluid and a preparation method thereof. Background technique [0002] Magnesium alloy has light weight, relatively high strength and rigidity, and is recyclable and has good machinability. Therefore, magnesium alloys have gained widespread attention in many fields such as aerospace, automobiles, and electronic appliances. [0003] However, due to the low ignition point and high activity of magnesium alloys, during the cutting process, due to the contact between the rake face of the tool and the cutting surface, severe friction occurs, the pressure is high, and the temperature is also high. Cooling will cause cracks and low-temperature welding or even burning on the surface of the magnesium part. At this time, the quality of the surface of the workpiece is low. [0004] Therefore, water-based magnesium alloy cutting fluid has gradually become a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04C10N30/16C10N40/22

CPCC10M169/048C10M2201/102C10M2207/022C10M2207/126C10M2207/142C10M2207/281C10M2207/402C10M2215/04C10M2215/042C10M2215/223C10M2219/104C10M2223/04C10M2225/04C10N2030/16C10N2040/22C10N2040/245

Inventor 杨灿唐波

Owner 安徽华灿润滑技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com