Method for making tussah silk summer sleeping mat and tussah silk summer sleeping mat

A manufacturing method and technology of tussah silk, which are applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of insufficient skin-friendly effect of tussah silk, simple organizational structure, and insufficiently delicate fabrics, and achieve good elasticity and fit. Good, non-wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The manufacturing method of the tussah silk summer mat of the present embodiment is as follows: adopt double weave weaving, the surface warp adopts tussah silk of 73.3 / 82.2dtex, the inner warp adopts pure cotton yarn of 72.9×2dtex, and the weft yarn adopts 73.3 / 82.2 Tussah silk of dtex; the arrangement ratio of the surface warp and the inner warp is 2:1 (two tussah silks are worn in the same heddle eye, that is, two are combined to make one); the surface weave adopts 5 / 2 warp satin, The inner weave adopts 5 / 3 weft satin; the surface warp density is 900 threads / 10cm, the inner warp density is 450 threads / 10cm, the weft density is 400 threads / 10cm, and the fabric width is 150cm (the fabric width can be designed according to the width of the bed. Specifications).

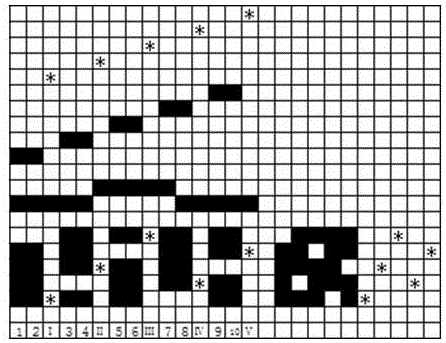

[0021] Weaving process:

[0022]

[0023] In order to achieve the effect of fineness and good luster of the tussah silk mat, the surface warp tussah silk used is thinner, and the processes of steaming, doubl...

Embodiment 2

[0027] The manufacturing method of the tussah silk summer mat of the present embodiment is as follows: adopt latitude double weave to weave, table weft adopts tussah silk of 73.3 / 82.2dtex, inner weft adopts polyester-cotton yarn of 130dtex, and warp yarn adopts tussah silk of 73.3 / 82.2dtex Silk; the arrangement ratio of surface weft to inner weft is 2:1; the surface weave is 8 / 5 weft satin, and the inner weave is 3 / 1 broken twill; the warp density is 400 threads / 10cm, the surface weft density is 900 threads / 10cm, and the inside The weft density is 450 threads / 10cm, and the fabric width is 180cm (the fabric width can be designed into different specifications according to the width of the bed).

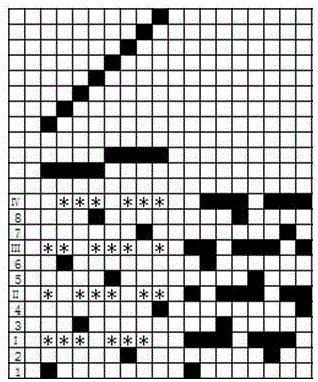

[0028] Weaving process:

[0029]

[0030] In order to achieve the effect of delicate tussah silk mats and good luster, the warp yarn tussah silk used is relatively thin, and the processes of steaming, doubling, twisting and sizing are reduced. 350~400r / min. Weaving is carried out o...

Embodiment 3

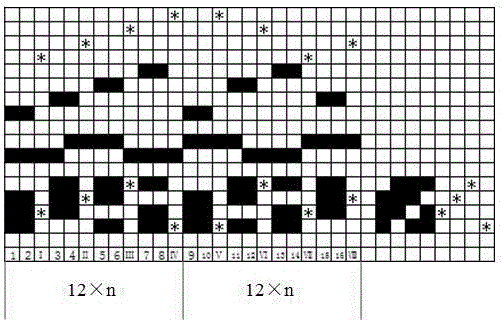

[0034] The manufacturing method of the tussah silk summer mat of the present embodiment is as follows: the surface weave adopts the stripe weave (3 / 1 twill + 4 pieces of satin weave) in the joint weave, and the inner weave adopts the stripe weave in the joint weave (1 / 3 Twill weave + 4 pieces change to weft satin weave).

[0035] The machine diagram of the weaving process in this embodiment is attached image 3 As shown, 3≤n≤30 in the figure, the larger the value of n, the wider the stripes.

[0036] Other implementations are the same as in Example 1. The surface of the tussah silk mat only shows the surface warp, not the inside warp and weft yarn. The surface of the tussah silk mat is all tussah silk, and the reverse side is pure cotton yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com