LNG (Liquefied Natural Gas)/liquid oxygen direct combustion mixed working medium power cycle generation device

A mixed working medium and power cycle technology, applied in the direction of machines/engines, liquefaction, steam generation, etc., can solve the problems of high energy consumption costs, and achieve the effects of reduced investment, simple system, and small storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

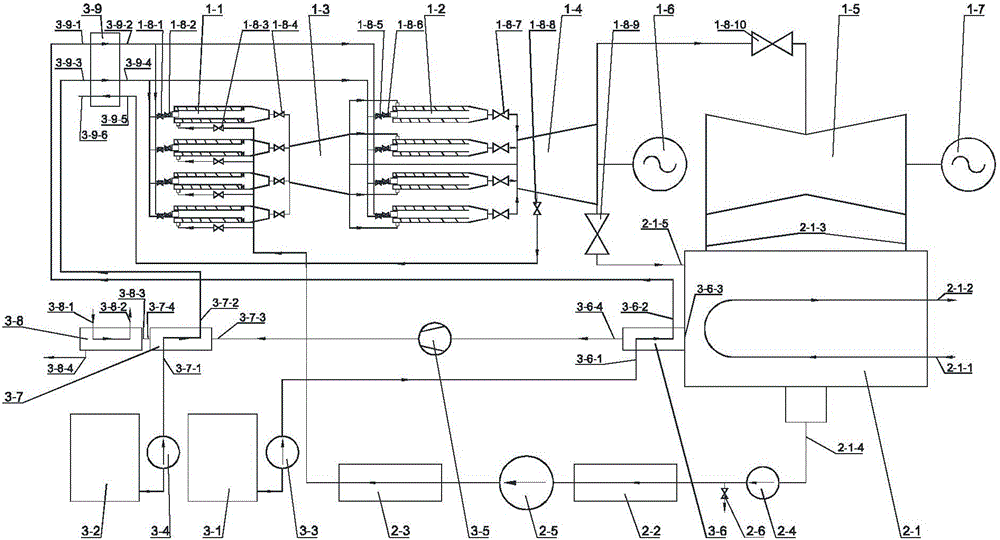

[0023] A LNG / liquid oxygen direct combustion mixed working medium power cycle power generation device, characterized in that it includes a work subsystem, a heat recovery cycle subsystem, and an LNG and liquid oxygen supply and CO2 capture subsystem, wherein,

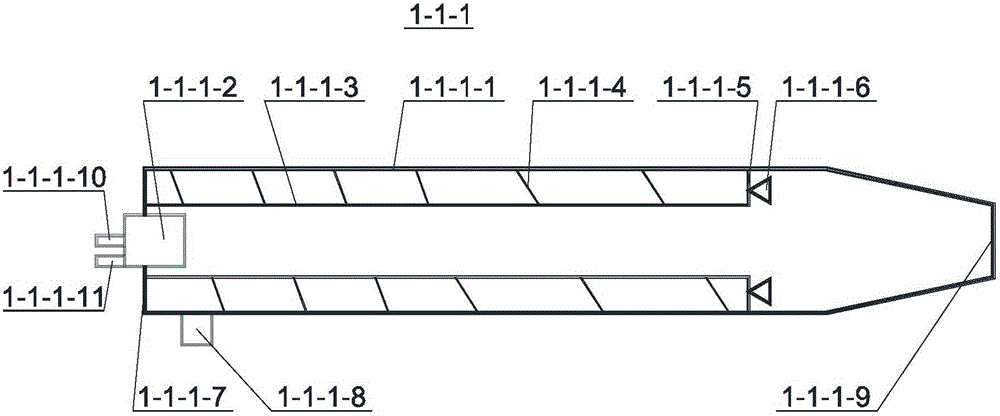

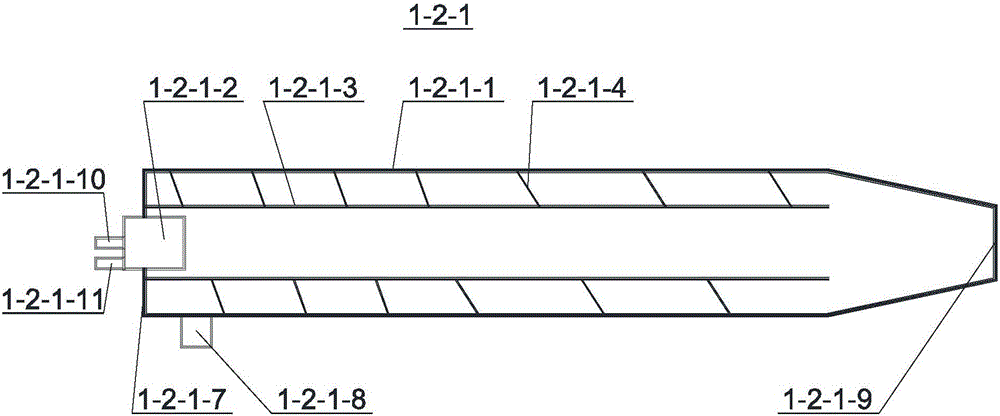

[0024]The working subsystem includes high-pressure combustor group 1-1, reheat combustor group 1-2, high-pressure turbine 1-3, medium-pressure turbine 1-4, low-pressure turbine 1-5, generator A1- 6. Generator B1-7 and valve group 1-8; the working subsystem uses H2O / CO2 mixed working fluid as the working fluid; the high-pressure combustion chamber group 1-1 is divided into 4 groups, corresponding to the The 4 steam inlet chambers of level 1-3, each high-pressure combustion chamber group 1-1 contains at least one high-pressure combustion chamber 1-1-1; the high-pressure combustion chamber 1-1-1 consists of a high-pressure combustion chamber cylinder 1- 1-1-1, high-pressure combustion chamber burner 1-1-1-2, high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com