A hybrid working fluid power cycle power generation system retrofitted for CO2 capture in existing power plants

A mixed working fluid and power generation system technology, which is applied in the petroleum industry, the manufacture of combustible gas, machines/engines, etc., can solve the problems of high energy consumption and other problems, and achieve the solution of the peak-valley difference problem of the power grid, small storage space, and simple system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

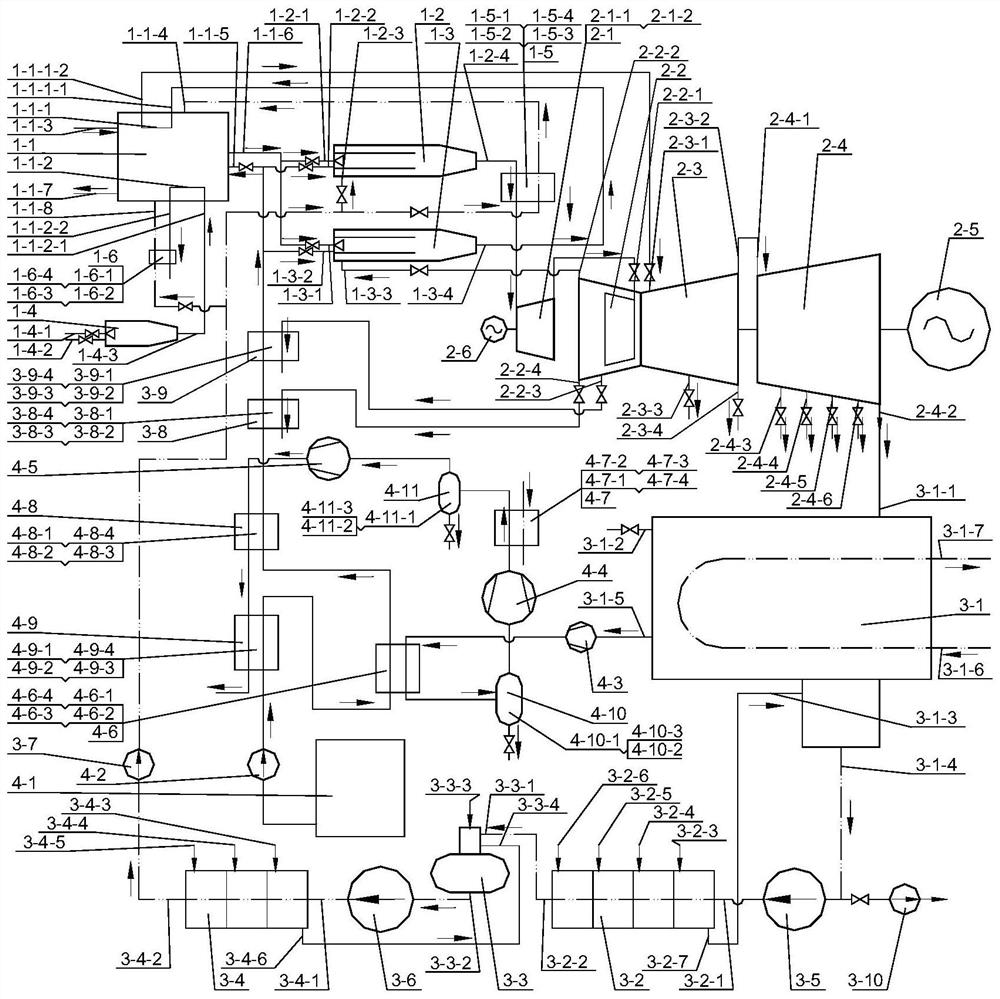

[0029] An existing power plant CO 2 Capture modified mixed working medium power cycle power generation system, including fuel and combustor subsystem, steam turbine subsystem, regenerative cycle subsystem, liquid oxygen supply and CO 2 capture subsystem; where,

[0030] The fuel and combustor subsystem includes a gasifier 1-1, a high-pressure combustor group 1-2, a reheat combustor group 1-3, an auxiliary combustor 1-4, a seventh heat exchanger 1-5, a Eight heat exchangers 1-6; the gasifier 1-1 is provided with a raw fuel inlet 1-1-3, a first supercritical water inlet 1-1-4, a third oxygen inlet 1-1-5, a fuel Gas outlet 1-1-6, residue outlet 1-1-7, second supercritical water inlet 1-1-8, first heat exchange surface 1-1-1, second heat exchange surface 1-1-2, The first heat exchange surface inlet 1-1-1-1, the first heat exchange surface outlet 1-1-1-2, the second heat exchange surface inlet 1-1-2-1 and the second heat exchange surface outlet 1- 1-2-2; the gasifier 1-1 uses co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com