Coke drying method of coke drying air distribution system for coke bin

An air distribution system and drying method technology, applied in the field of coke bins, can solve the problems of low heating and drying efficiency, uneven distribution of hot air, large fluctuations in coke moisture at the outlet of coke bins, etc., to achieve improved uniformity, improved uniformity, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

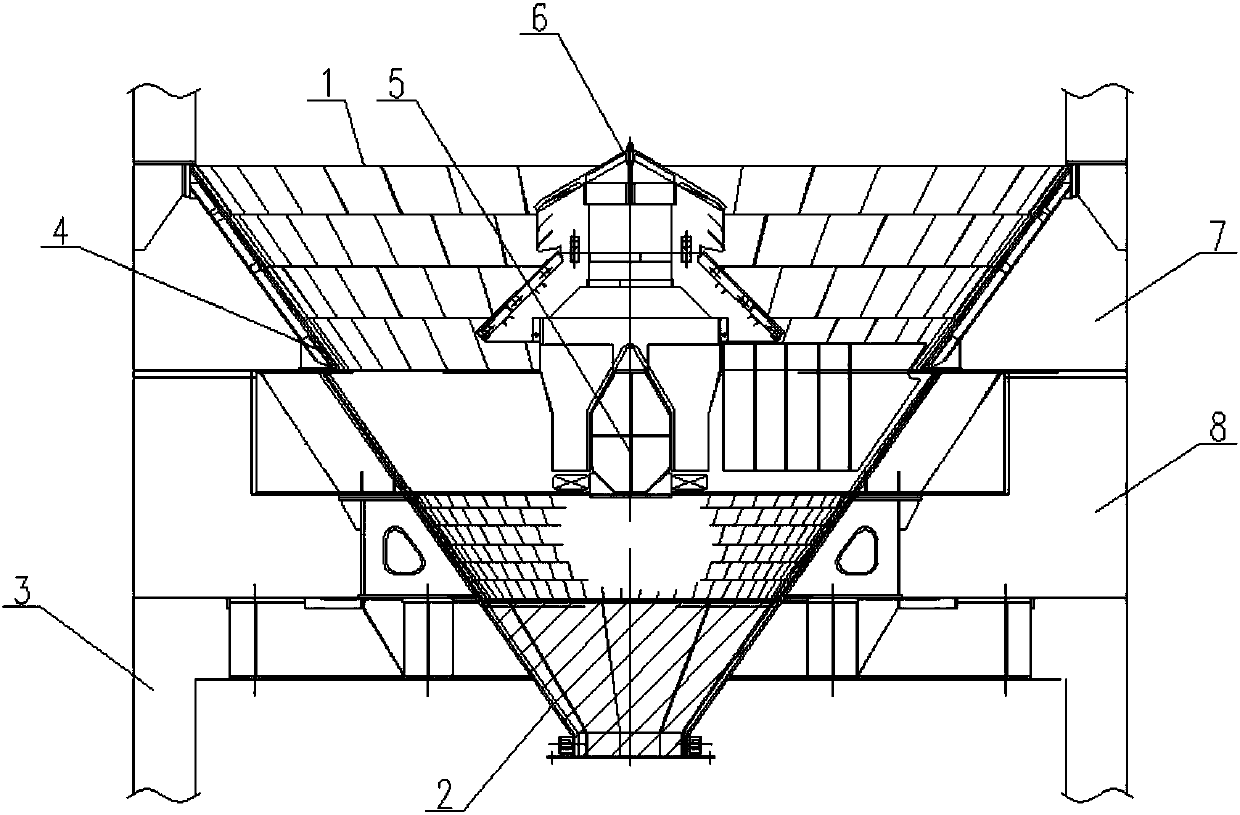

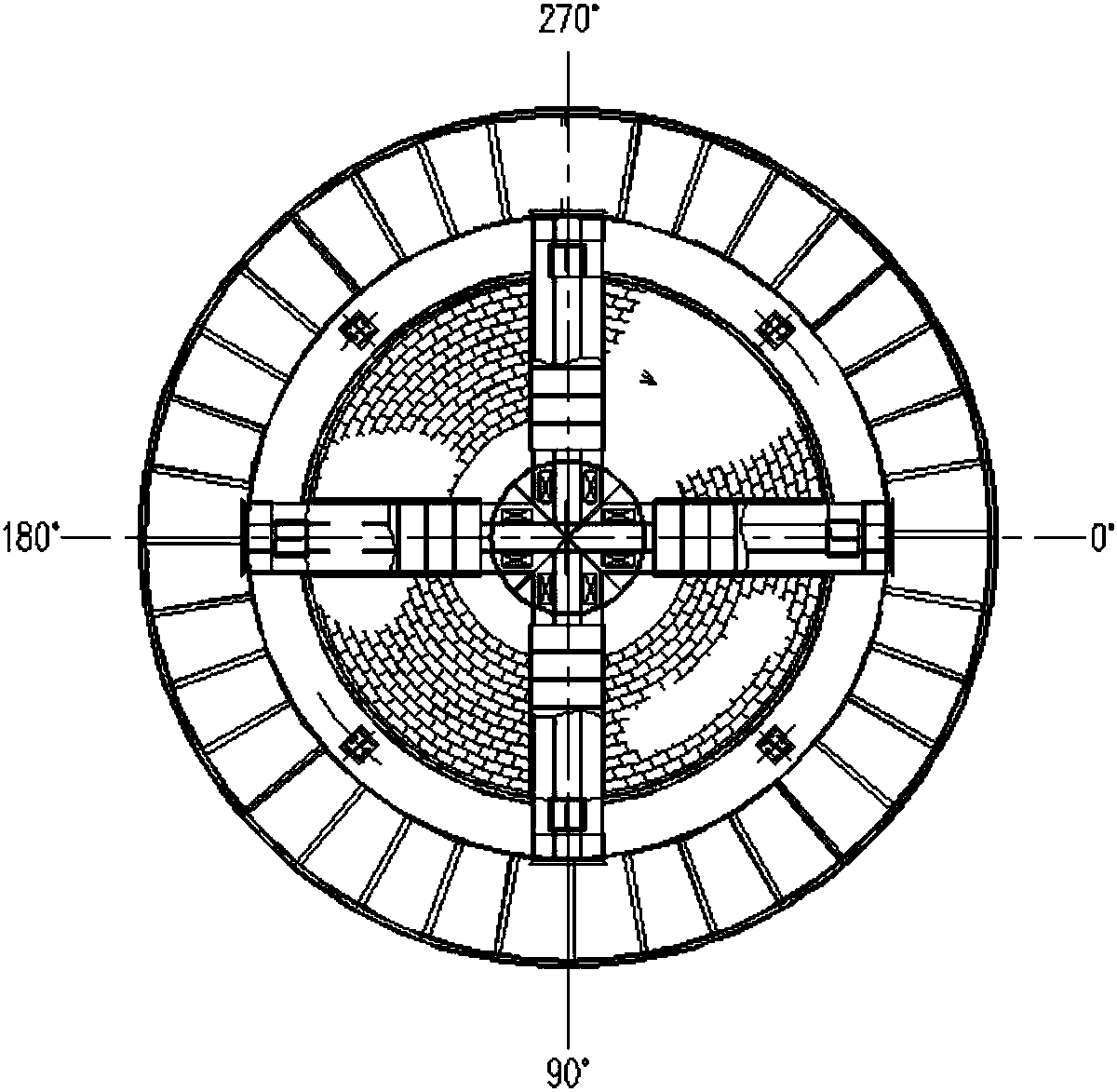

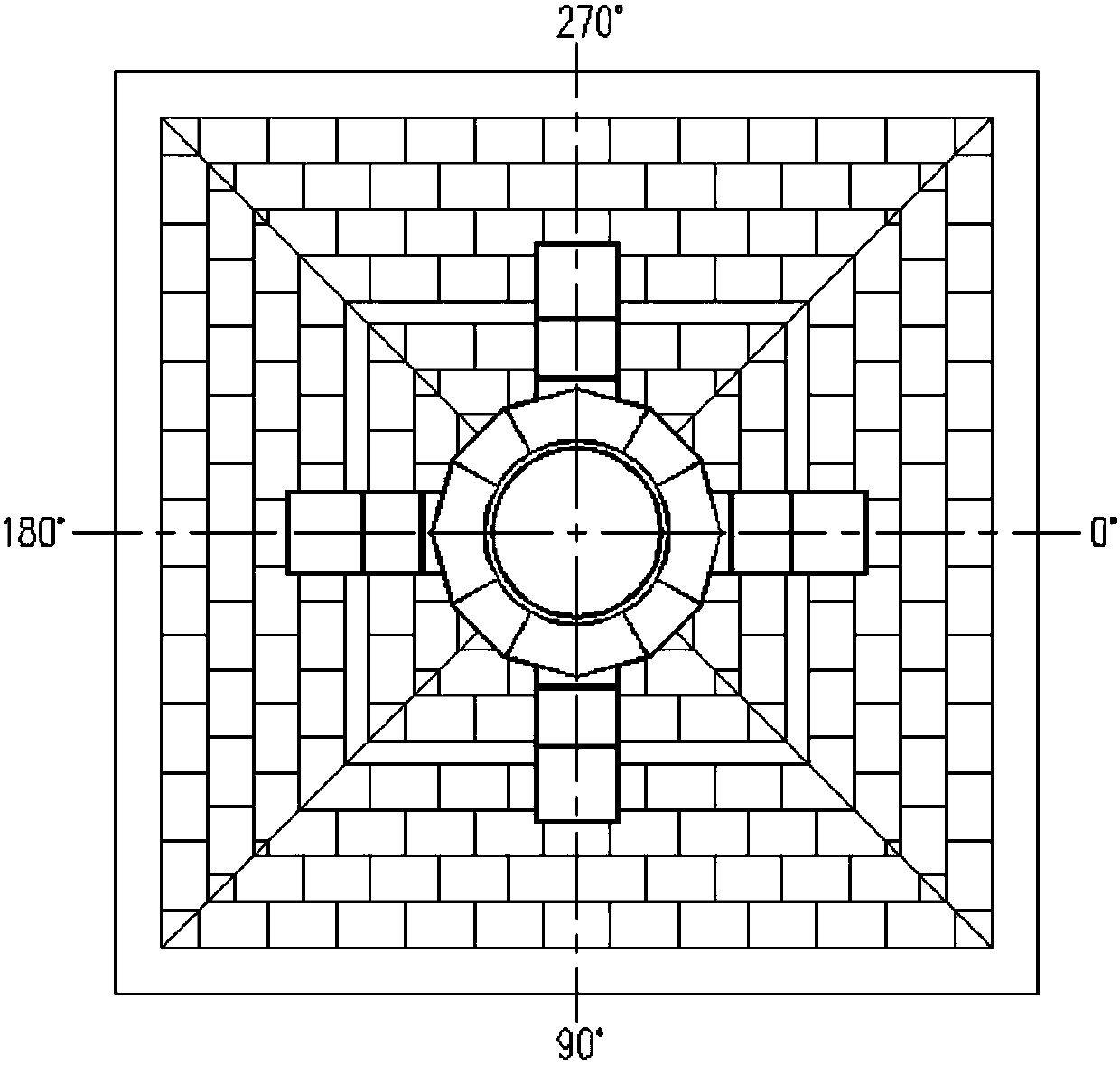

[0031] See figure 1 , the coke drying air distribution system for the coke bin of the present invention is arranged in the coke bin 3 and includes an upper cone bucket 1, a lower cone bucket 2, an annular air duct 4, a cross air duct 5 and a central air cap 6; the bottom of the coke bin 3 is provided with The upper cone bucket 1 and the lower cone bucket 2 are inserted together, and the annular gap formed by the sleeve eaves forms the annular air duct 4; the upper cone bucket 1 above the annular air duct 4 is equipped with an upper air chamber 7, and the annular air duct The lower cone bucket 2 below 4 is provided with a lower air chamber 8 outside, and the lower cone bucket 2 corresponding to the lower air chamber 8 is provided with a cross air duct 5 in communication with the central air cap 6 located in the center of the coke bin 3, and the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com