High-beam direct-current hollow cathode plasma source

A technology of plasma source and hollow cathode, which is applied in the field of plasma, can solve the problems of high flux density, low plasma flux density and low energy coupling efficiency that are difficult to simulate fusion reactors, so as to facilitate scientific research and process exploration, Improve conversion efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

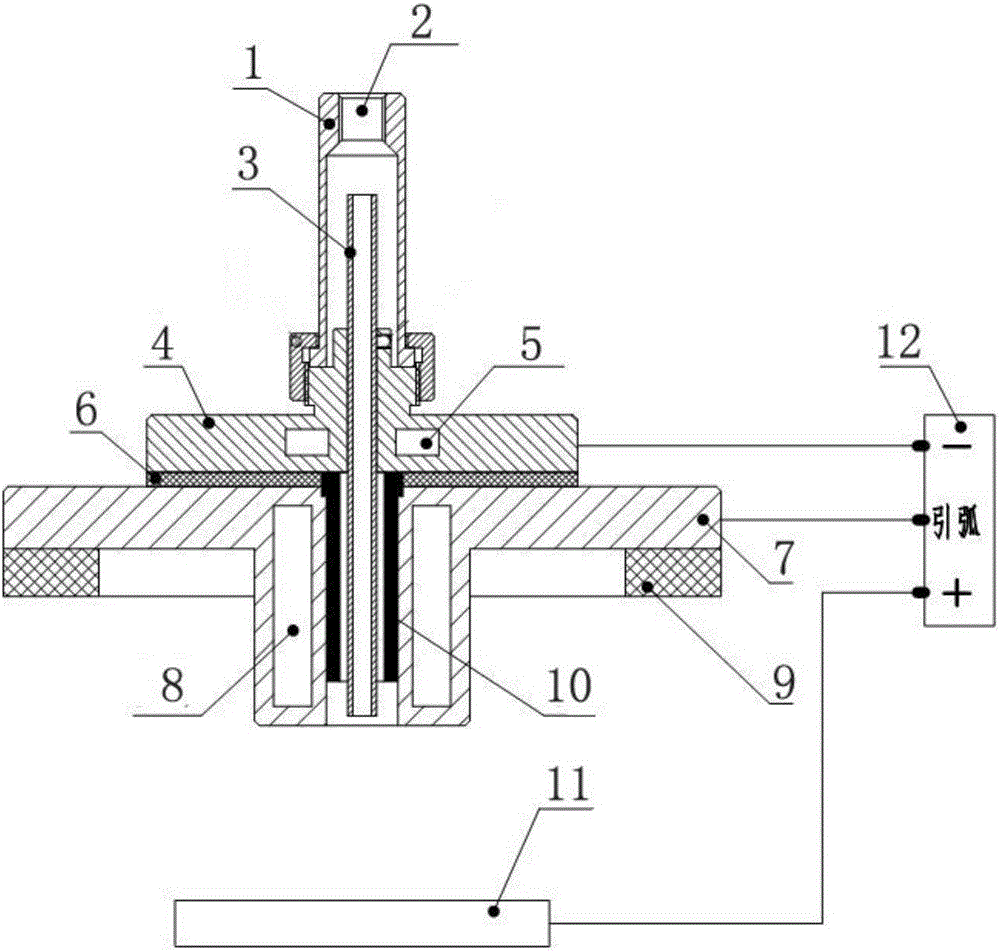

[0031] Such as figure 1 As shown, the present invention provides a high-beam DC hollow-cathode plasma source for material modification in a linear strong magnetic field device, which can generate a plasma beam with a high ionization rate. The invention includes a sealed tube 1 , a hollow electrode 3 , a cathode plate 4 , a connection plate 5 , a first anode plate 7 , a second anode plate 8 , an arc-starting spacer 10 and a control power source 12 . The hollow electrode 3 is installed on the cathode plate 4, which can be a tantalum tube or a tantalum alloy tube, and is locked on the central axis of the cathode plate 4 by screws. The sealed tube 1 is connected to the cathode plate 4, and the hollow electrode 3 is inserted therein to realize the sealing of the hollow electrode. The top of the sealed tube is also provided with a gas (such as Ar, He, N2, H2, etc.) Gas) is input to the gas inlet 2 in the hollow electrode 3. In this embodiment, when in use, the hollow electrode 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com