Integrated rotary oxygenating and feeding machine

A feeding machine and feed technology, applied in climate change adaptation, fish farming, application, etc., can solve the problems of low feed utilization rate, energy waste, limited service area, etc., to expand the service water body area and expand the service water body volume , oxygen-enhancing capacity and the effect of improving the utilization rate of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

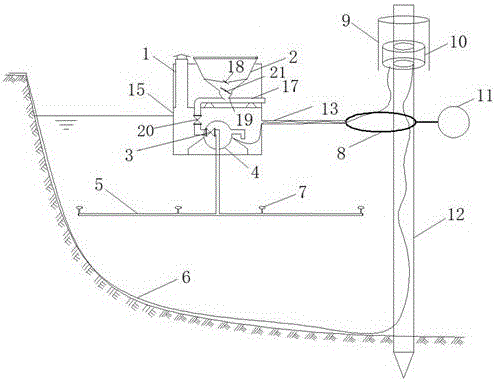

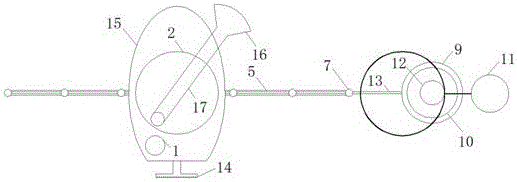

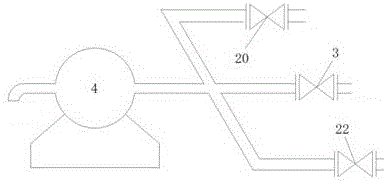

[0028]As shown in the figure, the integrated rotary aerobic feeding machine, the air enters through the ventilation pipe 1, and the high-pressure airflow is generated by the small high-pressure fan 4 installed in the boat-type floating tank 15, and part of it enters the aeration pipe through the aeration electromagnetic regulating valve 3 After 5, through the microporous aeration head 7, the water is aerated upwards to increase oxygen and stir the water body. A part of it enters the tail micropore through the propulsion air volume electromagnetic regulating valve 22 to push the plate 14, and generates horizontal thrust while aerating, so that the boat Formula buoyancy tank 15 rotates around center pile 12, also has a part to enter bait blowing pipe 17 through bait blowing electromagnetic regulating valve 20, and bait is blown to bait distribution mouth 16 and spreads on the water surface. The boat-type floating tank 15 is rigidly connected to the threading connecting rod 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com