A method for making Glitter soles, Glitter soles and shoes

A technology of Glitter and shoe soles, applied in the field of Glitter soles and shoes, making Glitter soles, can solve problems such as poor wear resistance, achieve good decorative effects, improve texture, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

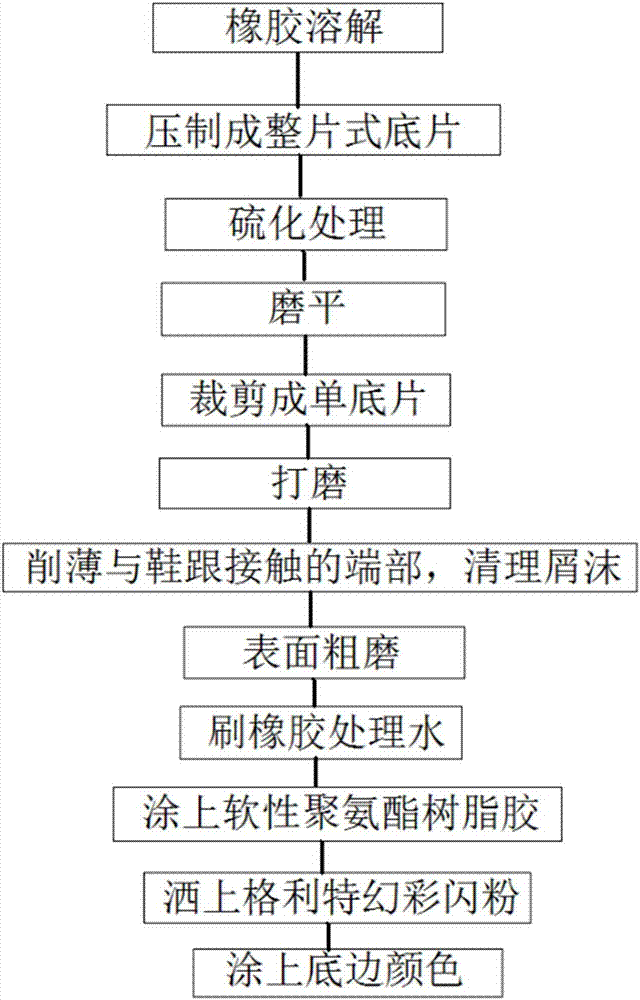

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The present invention is achieved like this, a kind of method for making Glitter sole, is characterized in that, it comprises the steps:

[0020] (1) Put the hard rubber particles into the refining furnace to dissolve, then press into a whole piece of film, and vulcanize; after vulcanization treatment, the structural strength of the film can be significantly improved, and its support and compression resistance can be improved;

[0021] (2) grinding the unevenness of the vulcanized monolithic negative film obtained in step (1), then cutting it into the single negative film needed, and polishing the circle of the single negative film smoothly; The negatives are ground flat, avoiding individual processing, which can significantly improve the automation level and production efficiency, and the control is simple and convenient; in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com