Stable promotive transfer film for olefin/alkane separation and preparation method thereof

A technology that promotes the transfer of membranes and stabilizes them. It is applied in separation methods, membrane purification/separation, and semipermeable membrane separations. It can solve the problems of industrial application limitations, carrier loss or reduction, carrier stability and separation performance decline, etc. Achieve the effect of improving separation selectivity and carrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

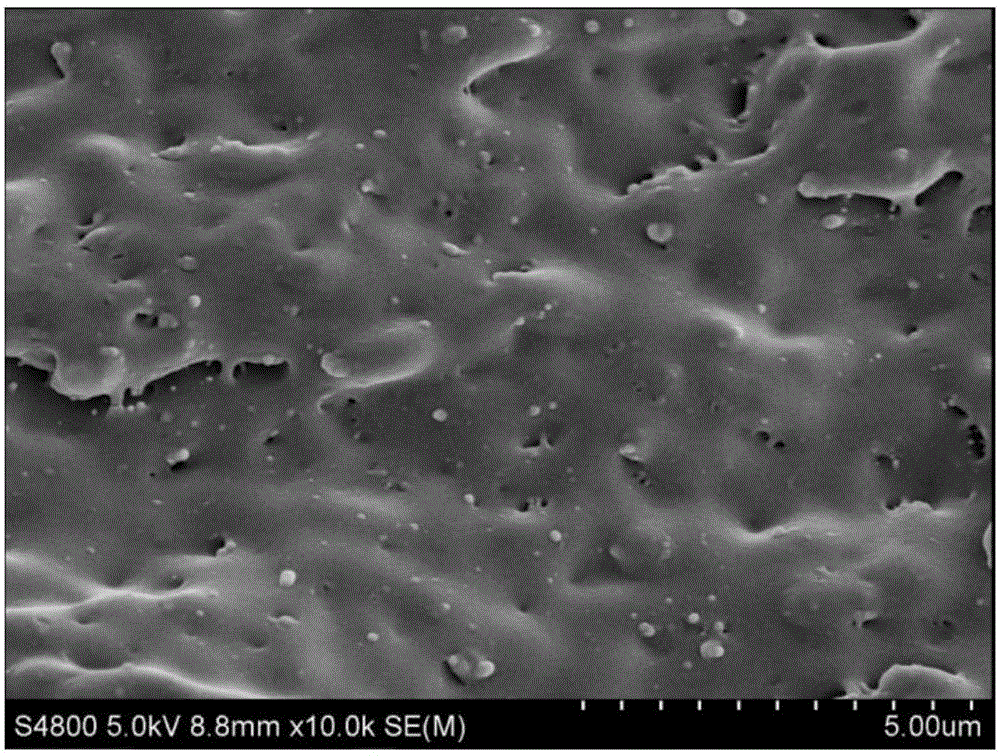

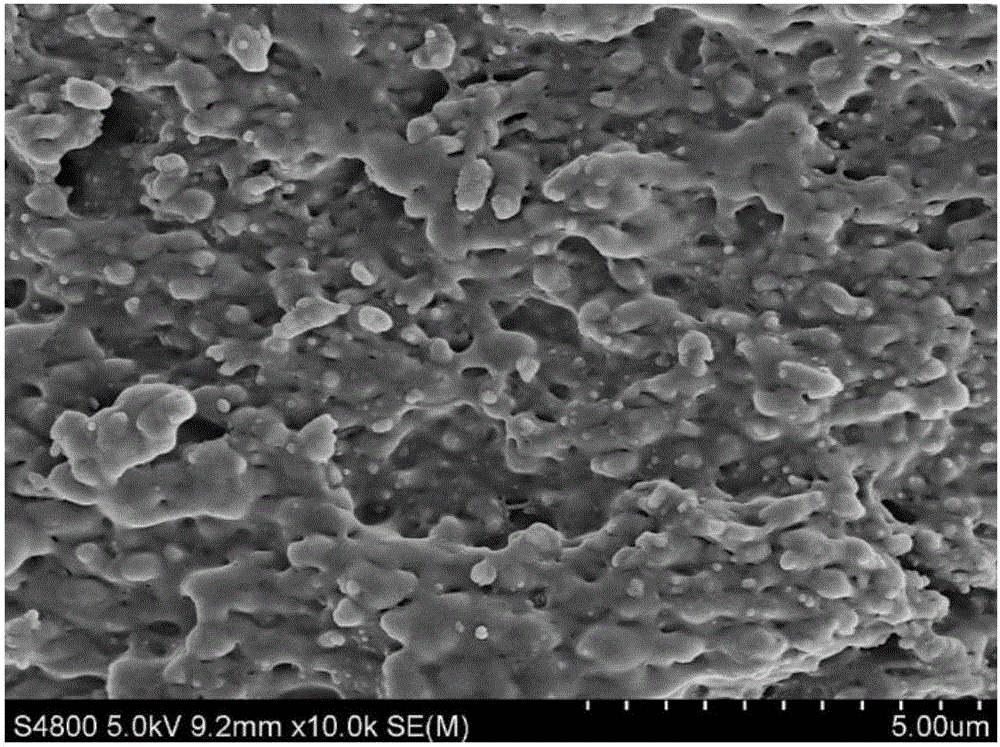

[0028] Dissolve 0.05g of TCNE in 10ml of absolute ethanol, and disperse evenly by ultrasonic; add 0.1g of silver nanoparticles, and disperse evenly by ultrasonic; take 2g of EC and dissolve it in 10ml of benzene, after fully dissolved, mix and stir with TCNE solution containing silver nanoparticles for 24h , and left to stand for 24 hours after filtration; the mixed solution was evenly coated on the PI base film, and placed in a drying oven to dry for 24 hours to obtain an EC / Ag / TCNE facilitated transport film loaded with silver nanoparticles. The olefin / alkane separation performance of the facilitated transfer membrane was tested with a constant volume variable pressure gas tester (test temperature was 30°C, test pressure was 0.1MPa), and its separation selectivity for propylene / propane was 8. After a week-long test period, the separation selectivity decreased slightly.

Embodiment 2

[0030] Dissolve 0.1g of TCNE in 10ml of absolute ethanol, disperse evenly by ultrasonic, add 0.1g of silver nanoparticles, and disperse evenly by ultrasonic; take 2g of EC and dissolve in 10ml of benzene, after fully dissolved, mix and stir with TCNE solution containing silver nanoparticles for 24h , and left to stand for 24 hours after filtration; the mixed solution was evenly coated on the PI base film, and placed in a drying oven to dry for 24 hours to obtain an EC / Ag / TCNE facilitated transport film loaded with silver nanoparticles. The olefin / alkane separation performance of the facilitated transfer membrane was tested with a constant volume variable pressure gas tester (test temperature was 30°C, test pressure was 0.1MPa), and its separation selectivity for propylene / propane was 10. After a week-long test period, the separation selectivity did not decrease significantly.

Embodiment 3

[0032] Dissolve 0.1g of TCNE in 10ml of absolute ethanol, disperse evenly by ultrasonic, add 0.2g of silver nanoparticles, and disperse evenly by ultrasonic; take 2.5g of EC and dissolve in 10ml of benzene, after fully dissolved, mix and stir with TCNE solution containing silver nanoparticles After filtering for 24 hours, let it stand for 24 hours; apply the mixed solution evenly on the PI base film, and place it in a drying oven to dry for 24 hours to obtain the EC / Ag / TCNE facilitated transport film with silver nanoparticles immobilized. The olefin / alkane separation performance of the facilitated transfer membrane was tested with a constant volume variable pressure gas tester (test temperature was 30°C, test pressure was 0.1MPa), and its separation selectivity for propylene / propane was 12. After a week-long test period, the separation selectivity did not decrease significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com