Coal biological flocculation coagulant aid and application method thereof

A technology of biological flocculation and application method, applied in the field of coagulation aids, can solve the problems of aggravating pipeline pressure, increasing rheology, increasing circulating water concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

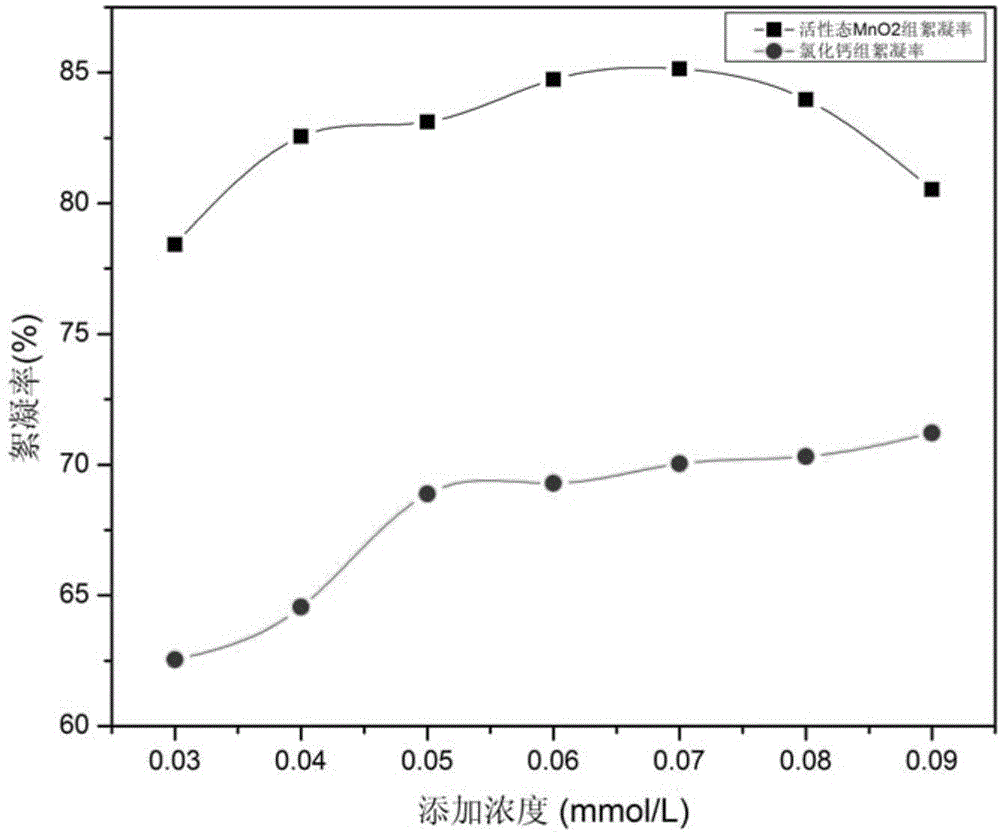

[0019] 1) Take 100mL of well-stirred coal slime water, then add 0.03mmol KMnO 4 and 0.045 mmol Na 2 SO 3 , stirred with a magnetic slow-speed stirrer for 30s; the control group also took 100mL of uniformly stirred slime water, and added 0.03mmol of CaCl 2 , Stir with a slow magnetic stirrer for 30 s.

[0020] 2) Use a pen-type pH meter to adjust the pH to 7 respectively, add 1ml corynebacterium glutamicum flocculant to both groups, then stir rapidly for 5 minutes, and let stand for 30 minutes.

[0021] 3) Aspirate the supernatant, and measure the absorbance values of the two groups of supernatants at 660nm with a UV-5100 ultraviolet spectrophotometer to obtain the active state MnO 2 The group flocculation rate is 78.421%, CaCl 2 The group flocculation rate is 62.544%.

example 2

[0023] 1) Take 100mL of well-stirred coal slime water, then add 0.04mmol KMnO 4 and 0.06mmolNa 2 SO 3 , stirred with a magnetic slow-speed stirrer for 30s; the control group also took 100mL of uniformly stirred slime water, and added 0.04mmol of CaCl 2 , Stir with a slow magnetic stirrer for 30 s.

[0024] 2) Use a pen-type pH meter to adjust the pH to 7 respectively, add 1ml corynebacterium glutamicum flocculant to both groups, then stir rapidly for 5 minutes, and let stand for 30 minutes.

[0025] 3) Aspirate the supernatant, and measure the absorbance values of the two groups of supernatants at 660nm with a UV-5100 ultraviolet spectrophotometer to obtain the active state MnO 2 The group flocculation rate is 82.544%, CaCl 2 The group flocculation rate is 64.554%.

example 3

[0027] 1) Take 100mL of well-stirred coal slime water, then add 0.05mmol KMnO 4 and 0.075 mmol Na 2 SO 3 , stirred with a magnetic slow-speed stirrer for 30s; the control group also took 100mL of uniformly stirred slime water, and added 0.05mmol of CaCl 2 , Stir with a slow magnetic stirrer for 30 s.

[0028] 2) Use a pen-type pH meter to adjust the pH to 7 respectively, add 1ml corynebacterium glutamicum flocculant to both groups, then stir rapidly for 5 minutes, and let stand for 30 minutes.

[0029] 3) Aspirate the supernatant, and measure the absorbance values of the two groups of supernatants at 660nm with a UV-5100 ultraviolet spectrophotometer to obtain the active state MnO 2 The group flocculation rate is 83.112%, CaCl 2 The group flocculation rate is 68.888%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com