Improved AAO wastewater treatment process for obtaining standard IV-class surface water

A technology for sewage treatment and surface water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as unrepaired water bodies and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

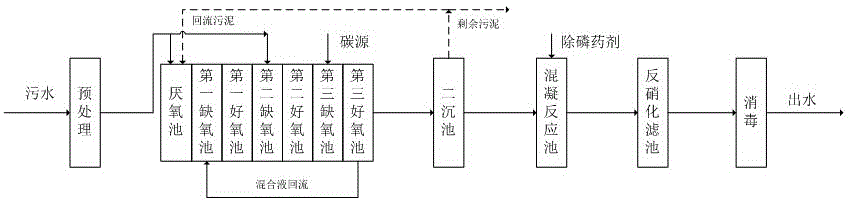

[0016] Such as figure 1 . The present invention proposes a kind of improved AAO sewage treatment process of standard surface water Class IV, comprising the following steps:

[0017] 1. The sewage produced by the sewage plant is pretreated and deposited in the grit chamber or sedimentation tank to remove SS in the water to ensure the stability of the subsequent biochemical reactions. SS refers to suspended solids in sewage.

[0018] 2. The effluent from the first stage of pretreatment first enters the anaerobic tank. In the anaerobic tank, the phosphorus accumulating bacteria use the organic matter in the raw water as carbon source and energy for anaerobic phosphorus release; the effluent mixture from the anaerobic tank enters the first anoxic tank , in the first anoxic tank, the denitrifying bacteria fully denitrify the unconsumed organic matter in the anaerobic tank as a carbon source, and convert the nitrate nitrogen carried in the mixed solution into nitrogen gas for remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com