Preparation method for reinforced low-resilience and low-alkaline liquid concrete accelerator

A low-rebound, concrete technology, used in the preparation of reinforced, low-rebound, low-alkali liquid concrete quick-setting admixtures, and the field of cement concrete quick-setting admixtures, which can solve unfavorable hydration reactions, accelerate ettringite, reduce concentration and other problems, to achieve the effect of simple process, increased concrete strength and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

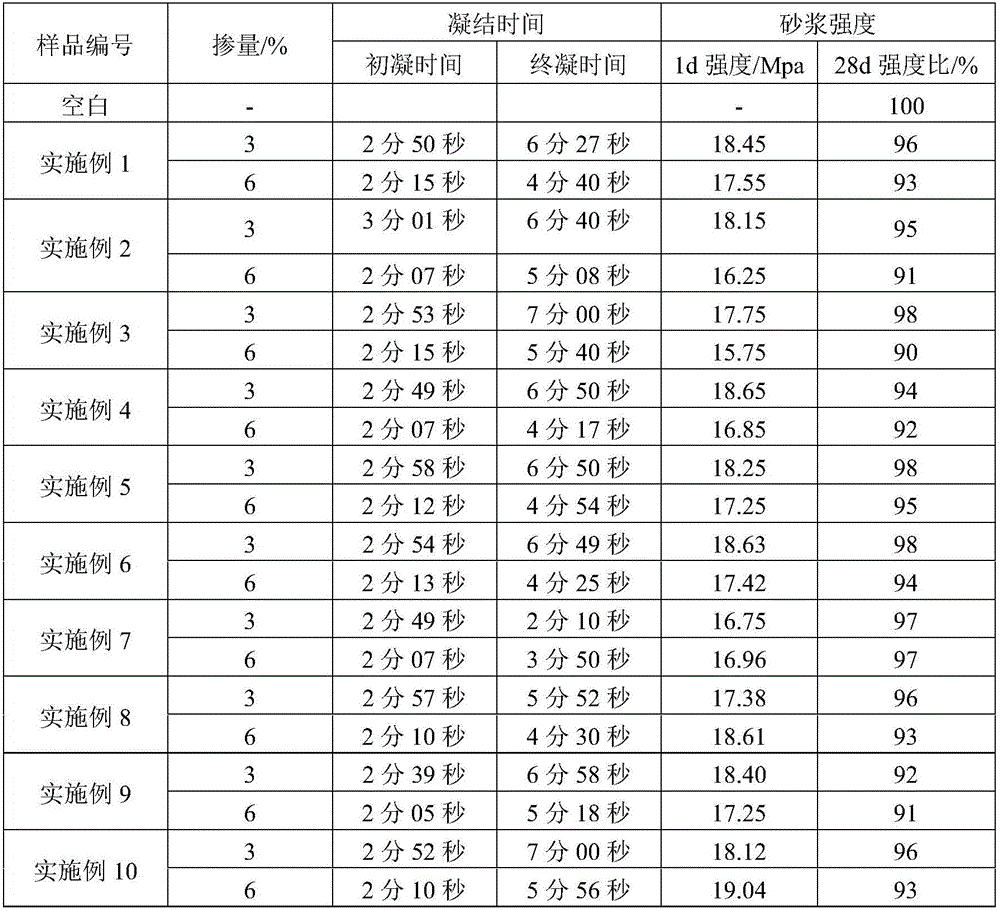

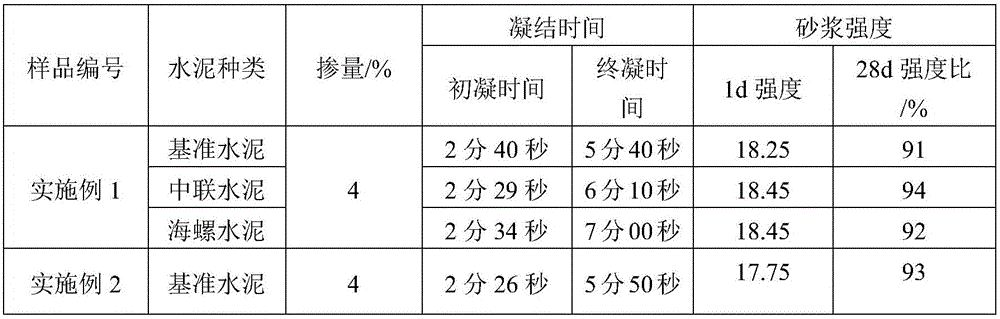

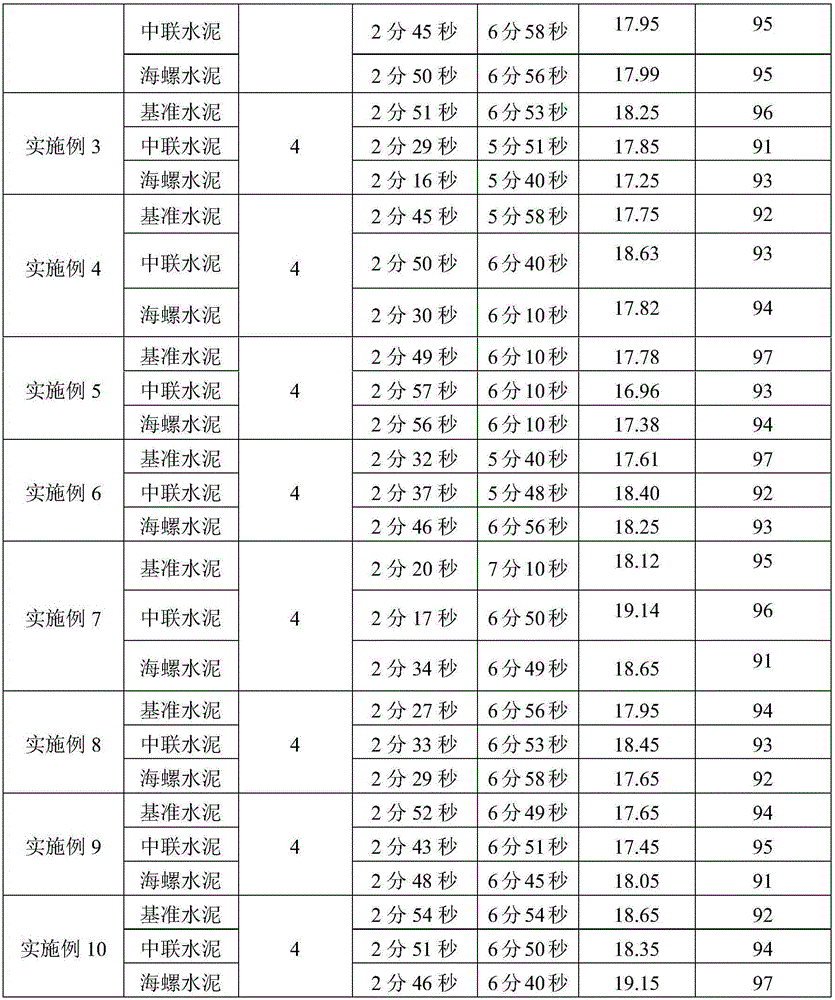

Examples

Embodiment 1

[0025] 1) The preparation method of modified alcohol amine organic small molecules: 1mol ethylenediamine and 4mol ethylene oxide are mixed at 25°C with 0.001molAlCl 3 Under the influence of the reaction for 1 hour, a small organic molecule with polyhydroxyl and polyamine groups is obtained, and then 2 mol of formic acid is added to react for 0.5 hour to obtain a modified alcohol amine organic molecule;

[0026] 2) Preparation of novel low-rebound, reinforced, and low-alkali liquid concrete quick-setting agent: 30% liquid modified sodium aluminate is added dropwise to 4.5% modified alkanolamine organic small molecules prepared in step 1). Add water at 30°C and stir for 1 hour, then add 0.3‰ polyacrylamide (relative molecular weight: 3 million) and stir for 5 minutes to prepare a new type of low-rebound, reinforced, and low-alkali liquid concrete accelerator.

Embodiment 2

[0028] 1) The preparation method of modified alkanolamine organic small molecules: 1mol p-phenylenediamine and 4mol propylene oxide were mixed at 30°C with 0.002molAlCl 3 After reacting for 1.5 hours under the action, a small organic molecule with polyhydroxy polyamine group was obtained, and then 2 mol of acetic acid was added to react for 0.5 hour to obtain a modified alcohol amine organic small molecule;

[0029] 2) Preparation of novel low-rebound, reinforced, and low-alkali liquid concrete quick-setting agent: 35% liquid modified sodium aluminate is added dropwise to 4% modified alcohol amine organic small molecules prepared in 1) step, at temperature Add water at 50°C and stir for 0.5 hours, then add 0.3‰ polyacrylamide (molecular weight: 5 million) and stir for 10 minutes to prepare a new type of low-rebound, reinforced, and low-alkali liquid concrete accelerator.

Embodiment 3

[0031] 1) The preparation method of modified alkanolamine organic small molecules: 1mol decanediamine and 4mol epichlorohydrin are mixed at 35°C with 0.003molFeCl 3 Under the action of reaction for 2 hours, a small organic molecule with polyhydroxy polyamine group was obtained, and then 2 mol of citric acid was added to react for 1 hour to obtain a modified alcohol amine organic small molecule;

[0032] 2) Preparation of novel low-rebound, reinforced, and low-alkali liquid concrete quick-setting agent: 49% liquid modified sodium aluminate is added dropwise to 3% modified alcoholamine organic small molecules prepared in 1) step, at temperature Add water at 30°C and stir for 1 hour, then add 0.2‰ polyacrylamide (molecular weight: 8 million) and stir for 15 minutes to prepare a new type of low-rebound, reinforced, and low-alkali liquid concrete accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com