Separation and purification method of gibberellins A7 (GA7)

A purification method and technology of gibberellin, which are applied in the field of separation and purification of gibberellin GA7, can solve the problems of low crystal purity and difficult problems of gibberellin, and achieve the advantages of improving crystal powder yield, good environmental protection conditions and expanding processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

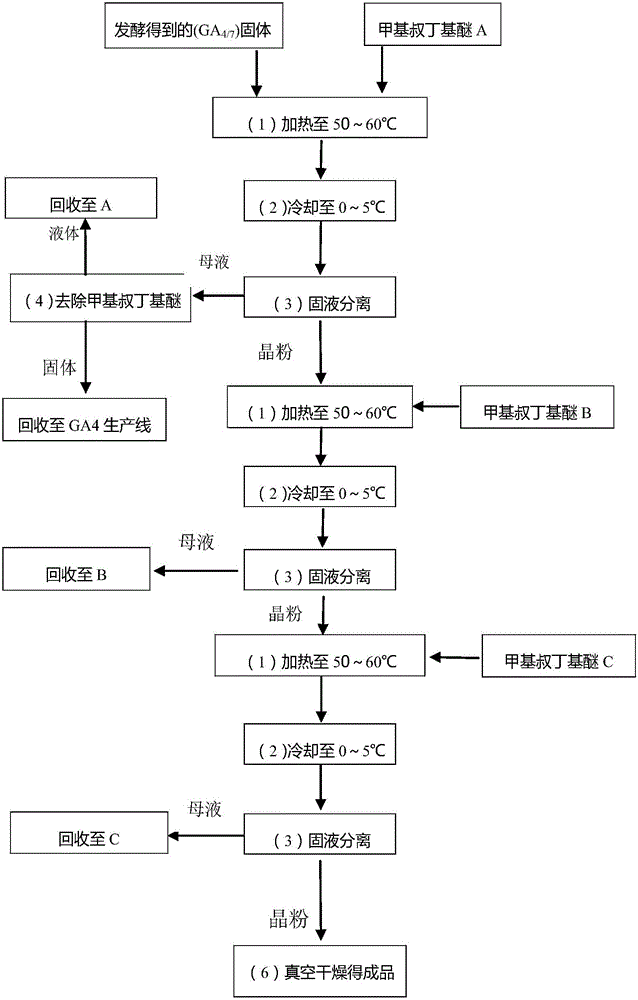

[0025] Such as figure 1 As shown, weigh 1000gGA 4 / 7 solid powder (GA 4 :GA 7 =60:40), added to 20L methyl tert-butyl ether, heated to 50-60°C until completely dissolved, cooled to 0-5°C to crystallize. Suction filtration or centrifugation, obtain wet powder 897.3g (dry=627.9g), after testing (GA 4 :GA 7 =42:58), dissolved in 12.5L (MTBE) by heating at 50g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 503.5g (dry=352.5g), after testing (GA 4 :GA 7 =27:73), dissolved in 8.8L (MTBE) by heating at 40g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 187.6g (dry=131.3g), after testing (GA 4 :GA 7 =12:88), dissolved in 4.4L (MTBE) by heating at 30g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 103.8g, after testing (GA 4 :GA 7 =5:95), oven vacuum dried to obtain crystal powder 67.4g, GA 7 The content is 95.4%.

Embodiment 2

[0027] Such as figure 1 As shown, weigh 1000gGA 4 / 7 solid powder (GA 4 :GA 7 =61:39), added to 20L methyl tert-butyl ether, heated to 50-60°C until completely dissolved, cooled to 0-5°C to crystallize. Suction filtration or centrifugation, obtain wet powder 887.1g (dry=620.9g), after testing (GA 4 :GA 7 =44:56), dissolved in 12.4L (MTBE) by heating at 50g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 486.5g (dry=340.5g), after testing (GA 4 :GA 7 =28:72), dissolved in 8.5L (MTBE) by heating at 40g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 181.3g (dry=126.9g), after testing (GA 4 :GA 7 =12:88), dissolved in 4.2L (MTBE) by heating at 30g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 98.8g, after testing (GA 4 :GA 7 =6:94), oven vacuum drying to obtain crystal powder 64.4g, GA7 content is 95.1%.

Embodiment 3

[0029] Such as figure 1 As shown, weigh 1000gGA 4 / 7 solid powder (GA 4 :GA 7 =62:38), added to 20L methyl tert-butyl ether, heated to 50-60°C until completely dissolved, cooled to 0-5°C to crystallize. Suction filtration or centrifugation, obtain wet powder 887.3g (dry=621.1g), after testing (GA4:GA 7 =45:55), dissolved in 15.5L (MTBE) by heating at 40g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 390.5g (dry=273.3g), after testing (GA4:GA 7 =27:73), dissolved in 6.8L (MTBE) by heating at 40g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 160.6g (dry=112.4g), after testing (GA4:GA 7 =12:88), dissolved in 3.7L (MTBE) by heating at 30g / L, cooled to 0-5°C to crystallize. Suction filtration, obtain wet powder 85.9g, after testing (GA 4 :GA 7 =6:94), oven vacuum drying to obtain crystal powder 55.8g, GA 7 The content is 94.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com