Polyvinyl alcohol coating film-forming solution for coating composite film and its preparation method and application

A polyvinyl alcohol and composite film technology, which is applied in the field of polyvinyl alcohol coating film-forming solution and its preparation to achieve the effects of improving composite quality, improving water resistance and moisture resistance, and stabilizing application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

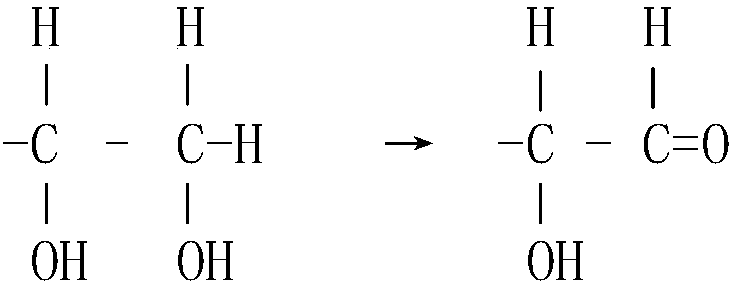

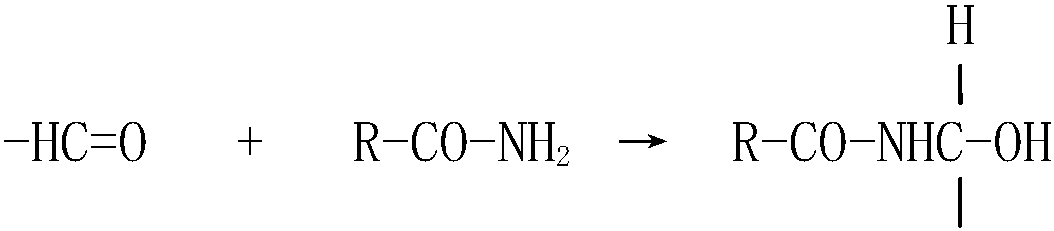

Method used

Image

Examples

Embodiment 1

[0037] The ratio of each combination of modified polyvinyl alcohol:

[0038]

[0039]

[0040] After the above-mentioned components are measured in proportion, first dissolve polyvinyl alcohol 2099 in water and heat to 90-95°C to fully dissolve. The ratio of polyvinyl alcohol 2099 to water is 8:92 (weight ratio). After fully dissolving the polyvinyl alcohol aqueous solution, keep the solution temperature at 60°C and stir, start adding hydrogen peroxide dropwise for 60 minutes; after adding the hydrogen peroxide, raise the temperature to 80°C and continue the reaction for 30 minutes. Then use triethylamine to adjust the pH of the solution to 10.0, add the carbonamide measured above while maintaining the solution temperature at 80°C, and carry out the methylolation reaction at 80°C for 60 minutes; cooling to room temperature is a coating compound of the present invention. The film-forming solution is coated with polyvinyl alcohol (PVA) for the film, and the permeability of...

Embodiment 2

[0042] The ratio of each combination of modified polyvinyl alcohol:

[0043]

[0044]After the above-mentioned components are measured in proportion, first dissolve polyvinyl alcohol 1799 and polyvinyl alcohol 0599 in water, and heat to 90-95°C to fully dissolve. The ratio of polyvinyl alcohol to water is 15:85 (weight ratio) . After fully dissolving the polyvinyl alcohol aqueous solution, keep the solution temperature at 70°C and stir, start adding hydrogen peroxide dropwise for 45 minutes; after adding the hydrogen peroxide, raise the temperature to 75°C and continue the reaction for 45 minutes. Then use diethylamine to adjust the pH of the solution to 9.0, add the carbonamide measured above while maintaining the solution temperature at 75°C, and carry out the methylolation reaction at 75°C for 80 minutes; then cooling to room temperature is a coating of the present invention. The polyvinyl alcohol (PVA) that composite film is used is coated with film-forming solution, a...

Embodiment 3

[0046] The ratio of each combination of modified polyvinyl alcohol:

[0047]

[0048] After the above-mentioned components are measured in proportion, first dissolve polyvinyl alcohol 2488 and polyvinyl alcohol 0588 in water, and heat to 90-95°C to fully dissolve. The ratio of polyvinyl alcohol to water is 12:88 (weight ratio) . After fully dissolving the polyvinyl alcohol aqueous solution, keep the solution temperature at 80°C and stir, start adding hydrogen peroxide dropwise for 60 minutes; after adding the hydrogen peroxide, cool down to 75°C and continue the reaction for 60 minutes. Then use triethanolamine to adjust the pH of the solution to 8.0, add the carbonamide measured above while maintaining the solution temperature at 75°C, and carry out the methylolation reaction at 75°C for 90 minutes; The film-forming solution is coated with polyvinyl alcohol (PVA) for the film, and the permeability of the composite film to oxygen is 8.8cm after film-forming with this coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com