A kind of epoxy resin matrix composite material and preparation method thereof

An epoxy resin matrix and epoxy resin technology, applied in the field of composite materials, can solve problems such as poor damping effect, poor strength and toughness, and achieve the effects of improving mechanical properties, simple steps and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of this epoxy resin-based composite material comprises the following steps:

[0043] (1) According to the volume ratio or mass ratio of polystyrene hollow spheres, polyethylene glycol and epoxy resin, polystyrene hollow spheres and polyethylene glycol are added to epoxy resin, at 40 ° C ~ 70 ° C, First use 600r / min-2000r / min high-speed mechanical stirring for 0.5h-2h to roughly disperse the polystyrene hollow spheres with low density in the epoxy resin, and then ultrasonically disperse them for 0.5h-2h to make the three evenly dispersed to obtain dispersion system; if direct ultrasound without mechanical stirring, polystyrene hollow spheres will float on the surface of epoxy resin in large quantities and it is difficult to mix;

[0044] (2) According to the mass ratio of curing agent, curing accelerator and epoxy resin, add curing agent and curing accelerator to the dispersion system obtained in step (1), first stir at 1200r / min~1600r / min for 2min~1...

Embodiment 1

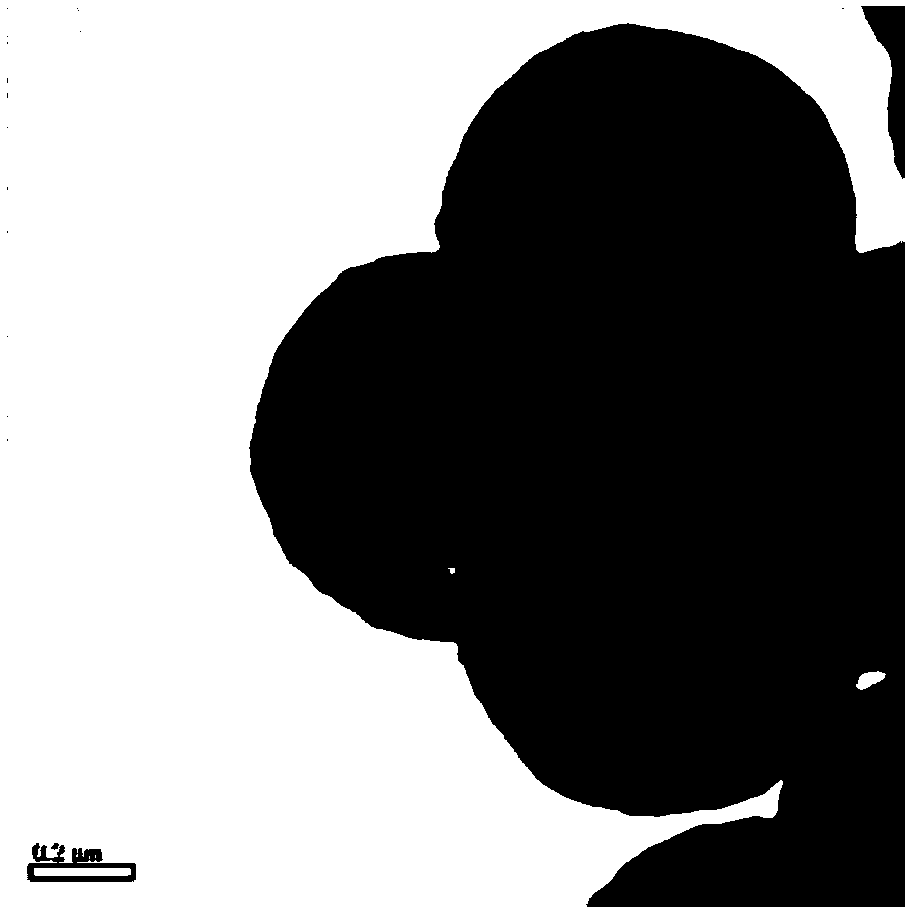

[0049] An epoxy resin-based composite material, comprising polystyrene hollow spheres, polyethylene glycol and E-44 bisphenol A type epoxy resin, the polystyrene hollow spheres and polyethylene glycol are uniformly dispersed in epoxy resin Among them, the polystyrene hollow spheres are added in an amount of 4.0vol.% of the epoxy resin matrix, and the polyethylene glycol is added in an amount of 10.0wt.% of the epoxy resin. The polystyrene hollow spheres have an outer diameter ranging from 500nm to 600nm, a wall thickness ranging from 50nm to 100nm, and a density of about 0.13g / cm 3 , the surface of the polystyrene hollow spheres contains carboxyl groups, which are dispersed in ethanol, and the morphology is observed with a transmission electron microscope, the results are as follows figure 1 As shown; the polyethylene glycol is PEG-600; the epoxy resin matrix is composed of epoxy resin, curing agent and curing accelerator, and the density is about 1.18g / cm 3 .

[0050] The...

Embodiment 2

[0057] An epoxy resin-based composite material, comprising polystyrene hollow spheres, polyethylene glycol and E-44 bisphenol A type epoxy resin, the polystyrene hollow spheres and polyethylene glycol are uniformly dispersed in epoxy resin Among them, the polystyrene hollow spheres are added in an amount of 8.0vol.% of the epoxy resin matrix, and the polyethylene glycol is added in an amount of 10.0wt.% of the epoxy resin matrix. The polystyrene hollow spheres have an outer diameter ranging from 500nm to 600nm, a wall thickness ranging from 50nm to 100nm, and a density of about 0.13g / cm 3 , the polystyrene hollow sphere surface contains carboxyl groups; the polyethylene glycol is PEG-600; the epoxy resin matrix is composed of epoxy resin, curing agent and curing accelerator, and the density is about 1.18g / cm 3 . The preparation method of described epoxy resin-based composite material, comprises the following steps:

[0058] (1) Add 14.3 grams of polyethylene glycol and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com