Method of manufacturing grain-oriented electrical steel sheet exhibiting low iron loss

A technology of electromagnetic steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, coil manufacturing, and the magnetism of inorganic materials, which can solve the problems of reduced production volume and achieve the effect of suppressing the extension of adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

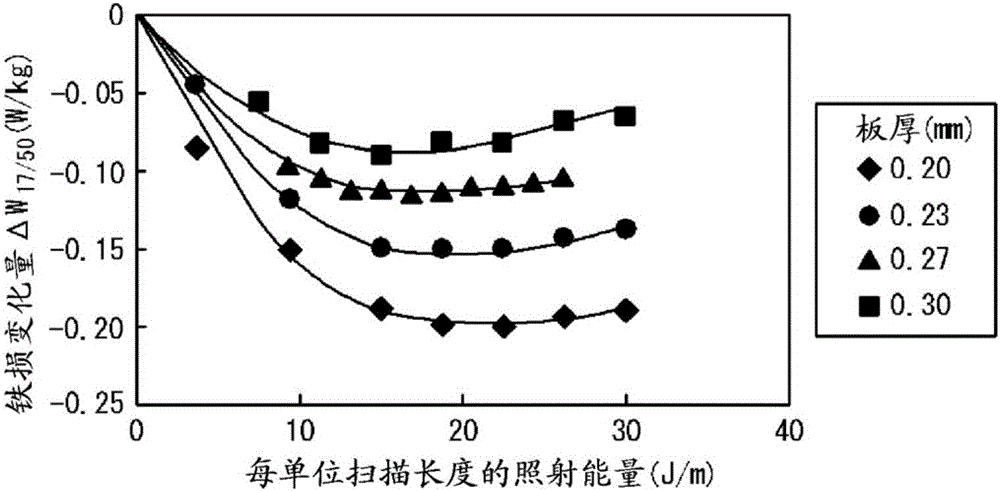

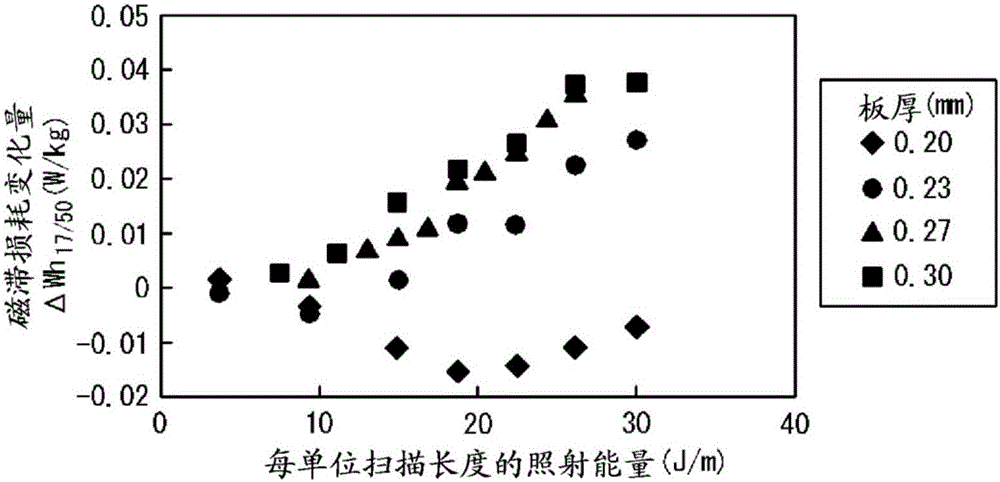

[0077] In this example, the head and tail ends of four grain-oriented electrical steel sheet coils of 1500 m each with a nominal thickness (t) of 0.23 mm, 0.27 mm, 0.30 mm, and 0.20 mm were bonded to each other and irradiated with electron beams.

[0078] Electron beam irradiation was carried out under the conditions of accelerating voltage of 60kV, beam diameter of 250μm, beam scanning speed of 90m / s, line angle of 90°, and chamber pressure of 0.1Pa, and the electron beam irradiation time of each coil was recorded. In addition, 4 m of the head and tail end portions of the coils of each plate thickness were set as regions (non-irradiated portions) that were not irradiated with electron beams.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com