Stainless steel pipeline cleaning agent and preparation method thereof

A pipeline cleaning agent, stainless steel technology, applied in the field of cleaning agent for dairy equipment, can solve the problems of stainless steel intergranular stress corrosion cracking and other problems, achieve the effect of prolonging the service life, low foam volume, easy to realize and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

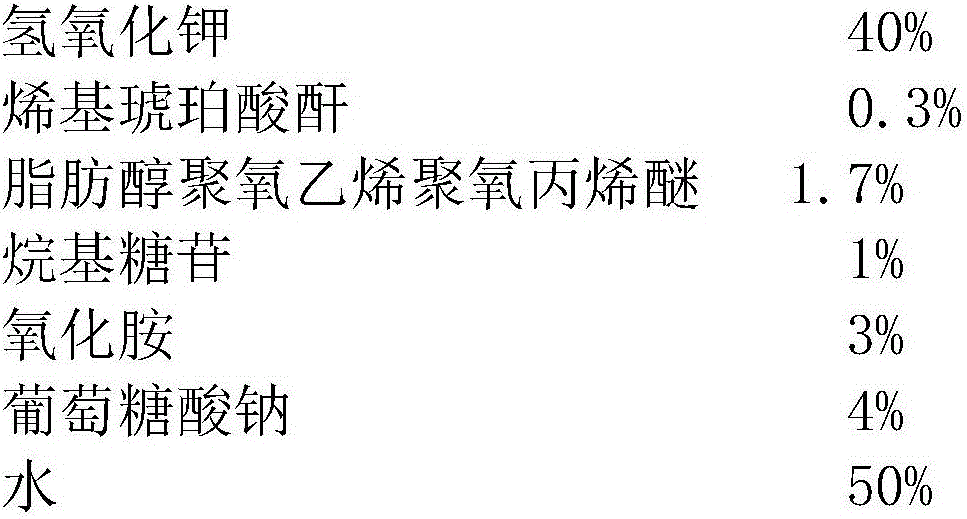

[0017] Stainless steel pipe cleaning agent consists of the following components in mass percentage:

[0018]

[0019] Preparation:

[0020] First add water to the container, then add surfactant, inorganic base, water co-solvent, fatty alcohol polyoxyethylene polyoxypropylene ether, alkyl glycoside and chelating agent in turn to mix, stir and dissolve, then filter to prepare, stirring speed The temperature is 100-250 rpm, the melting temperature is 20-30 degrees, and the filter screen adopts a double-layer 250-mesh filter screen.

Embodiment 2

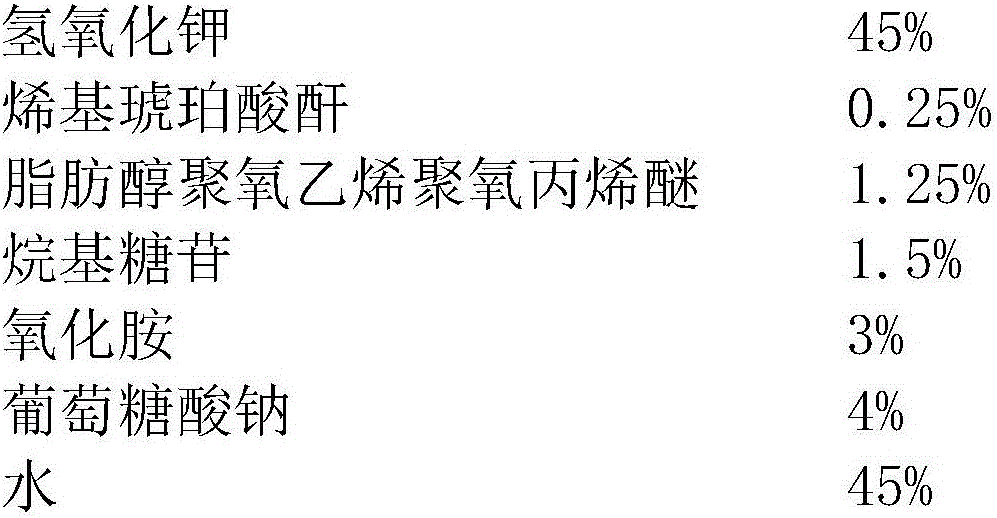

[0022] Stainless steel pipe cleaning agent consists of the following components in mass percentage:

[0023]

[0024] Preparation:

[0025] First add water to the container, then add surfactant, inorganic base, water co-solvent, fatty alcohol polyoxyethylene polyoxypropylene ether, alkyl glycoside and chelating agent in turn to mix, stir and dissolve, then filter to prepare, stirring speed The temperature is 100-250 rpm, the melting temperature is 20-30 degrees, and the filter screen adopts a double-layer 250-mesh filter screen.

Embodiment 3

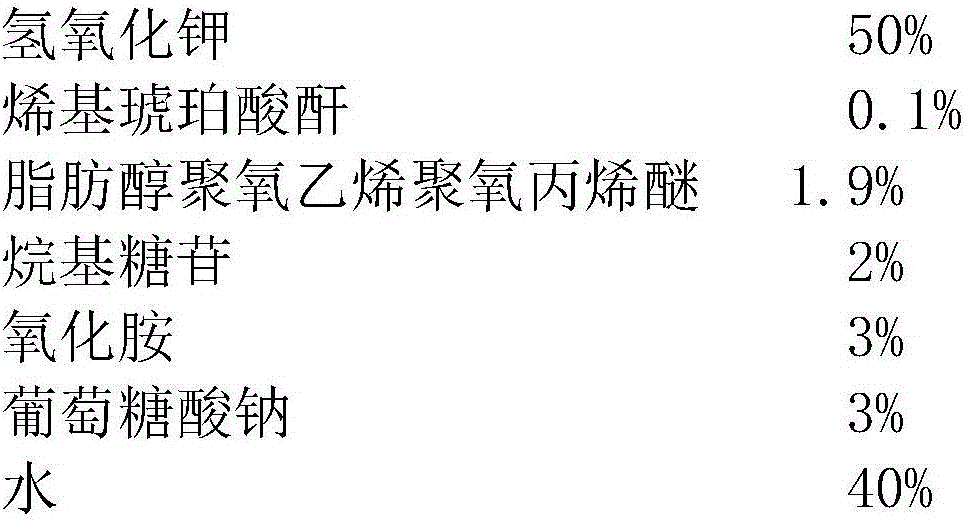

[0027] Stainless steel pipe cleaning agent consists of the following components in mass percentage:

[0028]

[0029] Preparation:

[0030] First add water to the container, then add surfactant, inorganic base, water co-solvent, fatty alcohol polyoxyethylene polyoxypropylene ether, alkyl glycoside and chelating agent in turn to mix, stir and dissolve, then filter to prepare, stirring speed The temperature is 100-250 rpm, the melting temperature is 20-30 degrees, and the filter screen adopts a double-layer 250-mesh filter screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com