Aluminum electrolysis cell with aluminum as cathode

An aluminum electrolytic cell and electrolytic cell technology, which are applied in the field of aluminum electrolytic cells with aluminum as a cathode, can solve the problems of electrolytic aluminum liquid pollution, insufficient energy utilization efficiency of aluminum electrolysis, increase power consumption of aluminum electrolysis, etc., and achieve the elimination of aluminum oxide. The effect of precipitation and elimination of defects in honeycomb microbattery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

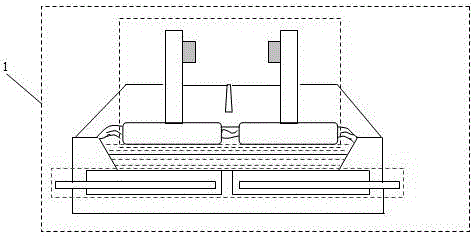

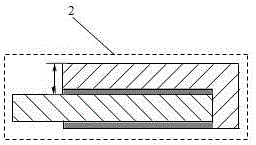

[0021] Aluminum electrolytic cell with aluminum as cathode, its structure includes: prebaked anode 3, feeding device 4, dust purification device 5 (see Figure 5 ); the structure of its cathode system 6 (see Figure 5 , Image 6 )include:

[0022] Electrolyzer body 6a (see Figure 5 ), the electrolytic cell body is a concave cell body made of refractory-insulation material; the upper edge of the electrolytic cell body is provided with a groove side 6b (see Image 6 );

[0023] Cathode partition wall 6c, this partition wall is two partition walls that are respectively arranged in the sides of the two ends of the electrolytic cell body and fixedly connected with the inner wall of the side of the electrolytic cell body. There is a bottom channel between the lower bottom of the bottom; the cathode partition wall and the inner wall of the side channel at the end of the electrolytic aluminum tank body;

[0024] Cathode busbar 7, the cathode busbar enters the electrolytic cell b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com