Anodic oxidation hanging tool suitable for square hole pipe fitting and mounting and hanging method

A technology for anodizing hangers and pipe fittings, which is applied in the direction of anodizing, electrolytic components, electrolytic coatings, etc. It can solve the problems of fast and reliable installation of square hole pipe fittings, avoid poor contact, improve installation efficiency, and conduct electricity. sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: An anodized hanger suitable for square hole pipe fittings.

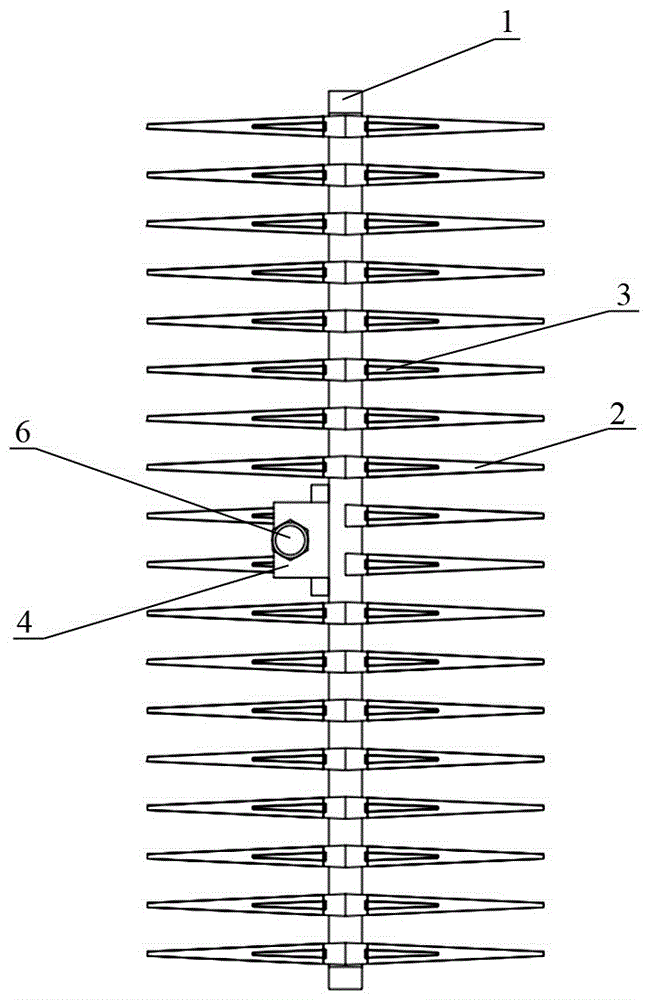

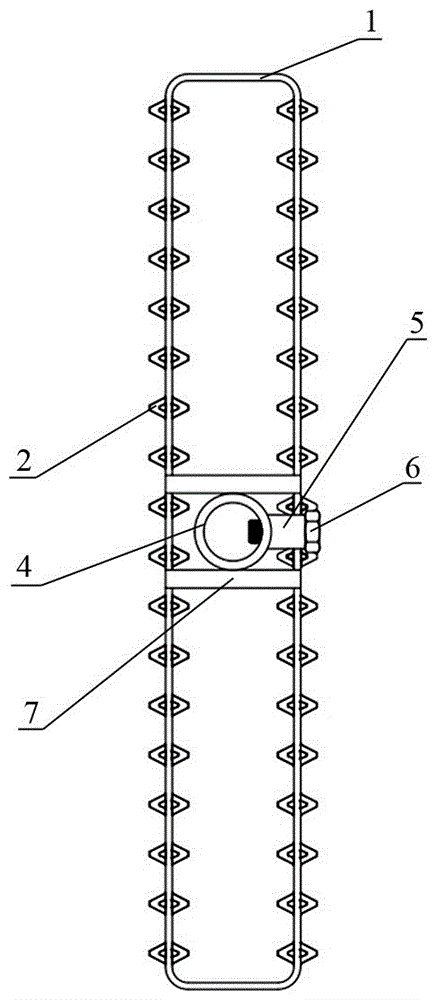

[0030] Such as Figure 1~Figure 3 As shown, the hanger of the present invention is mainly composed of a main frame 1 and hanging teeth 2 and the like.

[0031] Such as figure 2 As shown, the main frame 1 is the carrier of the entire hanger, and is also an intermediate electrical conductor that ensures the electrical connection between the hanging teeth 2 and the anode rod. It is a rectangular frame surrounded by titanium alloy strips. Two connecting plates 7 parallel to each other are arranged between the two long side plates of the main frame 1 to improve the strength of the main frame 1, and a fixing ring 4 is arranged between the two connecting plates 7, and its inner diameter is larger than that of the anode The outer diameter of the rod, and the central axis of which is perpendicular to the plane where the main frame 1 is located, is used to be sleeved on the outside of the anode rod to s...

Embodiment 2

[0035] Embodiment 2: A method for mounting and hanging pipe fittings with square holes.

[0036] The inventive method comprises the following steps:

[0037] A, the said anodized hanger that embodiment 1 is applicable to square hole pipe fittings is set;

[0038] b. Set the fixing ring 4 of the hanger on the rod body of the anode rod, pass the screw 6 through the screw hole on the connecting block 5, and make the end of the screw 6 stand on the anode rod, and tighten the screw 6;

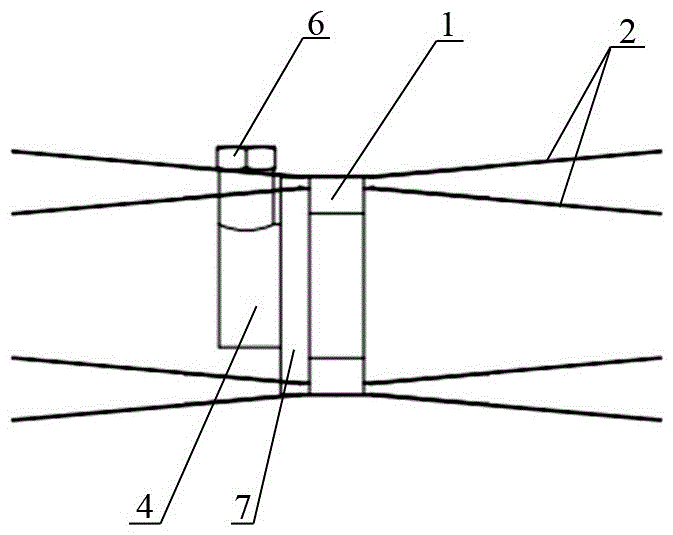

[0039] c. Pinch a pair of hanging teeth 2 with your hands so that the distance between the heads of the two hanging teeth 2 is smaller than the inner cavity width of the square hole pipe fitting to be installed, put the square hole pipe fitting on the set of hanging teeth 2, and let go. Hanging tooth 2 rebounds to fix the square hole pipe fitting;

[0040] d. During the anodizing process, the oxidizing liquid in the inner cavity of the workpiece is discharged through the liquid guiding groove 3 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com