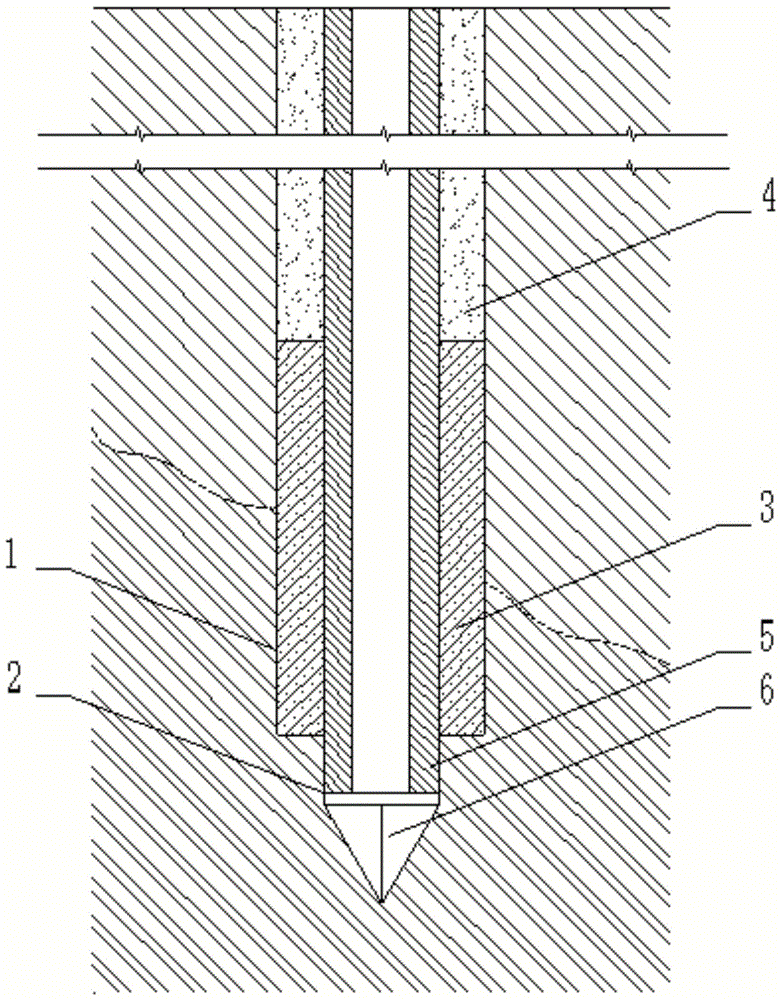

Drilling backfill end bearing pile foundation and construction method thereof

A technology of end-bearing piles and foundations, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as waste of raw materials, long construction period, quality problems, etc., to increase the force-bearing area and increase the bearing capacity of pile foundations force, increase the effect of pile bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to the geological and construction conditions, the drilling machine is used to drill holes with a diameter of 400mm at the pile forming position to 1m deep into the bearing rock formation, and the drilling slag is discharged in the form of dry discharge.

[0031] To clear the hole, inject 0.5 cubic meters of M7.5 mortar with a certain consistency into the pile hole at a time.

[0032] After the mortar is injected, backfill the slag discharged from the borehole into the pile hole until it is completely filled.

[0033] After the backfilling is completed, before the mortar sets, the PHC pipe pile with a diameter of 300mm equipped with a precast concrete pile tip is adjusted and positioned at the center of the pile hole according to the hammer sinking pile construction method, so that the deviation between the central axis of the pile body and the axis center of the pile hole is less than 30mm, hammering the pile, and the pile can be connected halfway until the e...

Embodiment 2

[0035] According to the geological and construction conditions, the drilling machine is used to drill holes with a diameter of 600mm at the pile forming position to 5m deep into the bearing rock formation, and the drilling slag is discharged in the form of dry discharge.

[0036] To clear the hole, inject 1 square of 1:0.5 high-consistency cement slurry mixed with thickener into the pile hole at one time.

[0037] After the cement slurry is injected, backfill the pile hole with solid waste until it is completely filled.

[0038] After the backfill is completed, before the cement slurry solidifies, the PHC pipe pile with a diameter of 500mm equipped with a steel pile point is adjusted and positioned at the center of the pile hole according to the construction method of hammer sinking pile, so that the center axis of the pile body deviates from the axis center of the pile hole If it is less than 30mm, sink the pile by hammering, and the pile can be connected halfway until the en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com