Pneumatic type canal lining cleaning machine

A washing machine, pneumatic technology, applied in earth mover/excavator, construction, etc., to achieve the effect of ensuring versatility, convenient disassembly and assembly, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

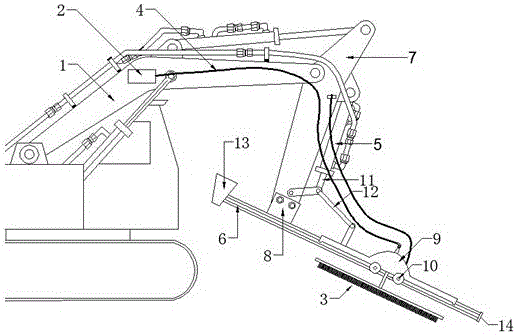

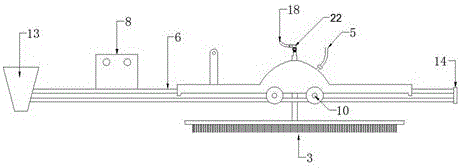

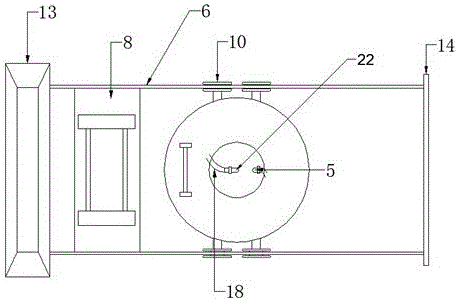

[0023] figure 1 It is the overall assembly diagram of the machine, and the present invention is a further invention based on the excavator 1 structure, so the main body part of the fuselage adopts the fuselage of a general crawler excavator; Depending on the size of the disc brush 3, the larger the brush needs the higher the air pressure; the high-pressure gas discharged by the high-pressure air pump 2 is transported to the cleaning module through the air guide tube 4, and the gas accumulated in the wheel housing 16 of the cleaning module is provided by a special The exhaust pipe 5 of the excavator is discharged; the guide rail 6 is rigidly connected with the machine arm 7 of the excavator 1 through the connecting plate 8, and the inclination angle of the guide rail 6 can be adjusted by adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com