Fabricated tunnel support system and construction method thereof

A construction method and prefabricated technology, applied in tunnels, tunnel linings, shaft equipment and other directions, can solve problems such as cracking, leaking water lining, large deformation, etc., and achieve the effects of low cost, reliable project quality, and improved self-bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

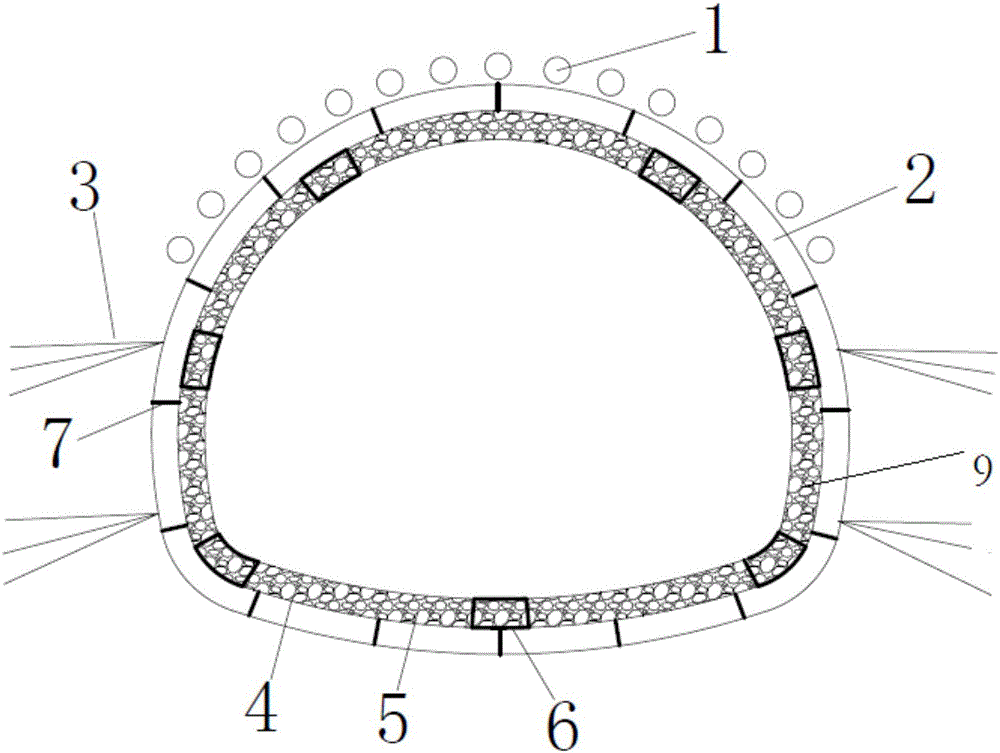

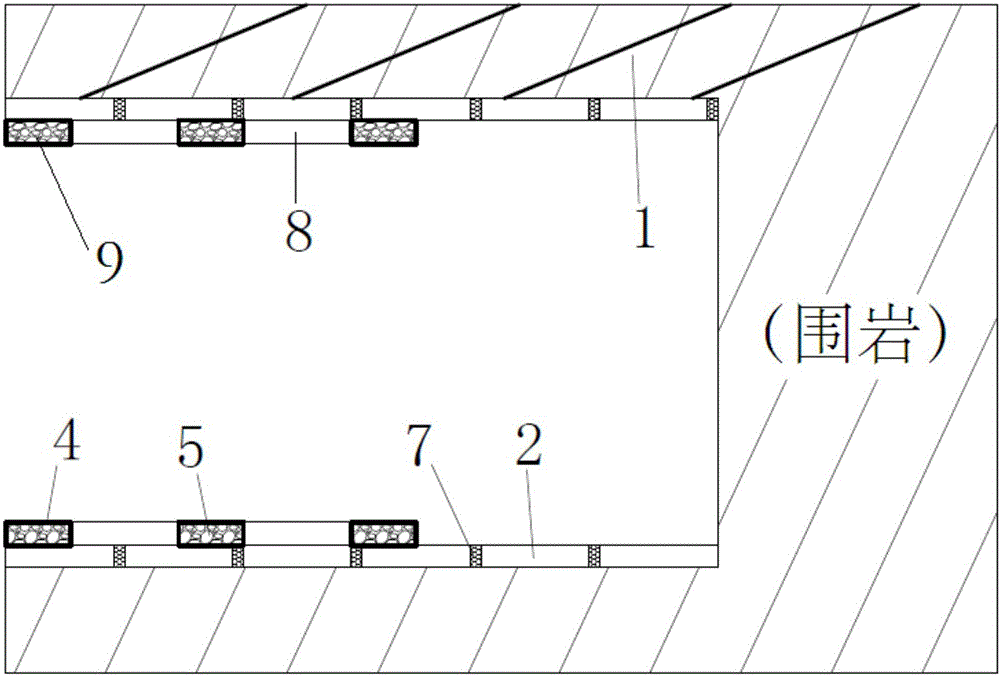

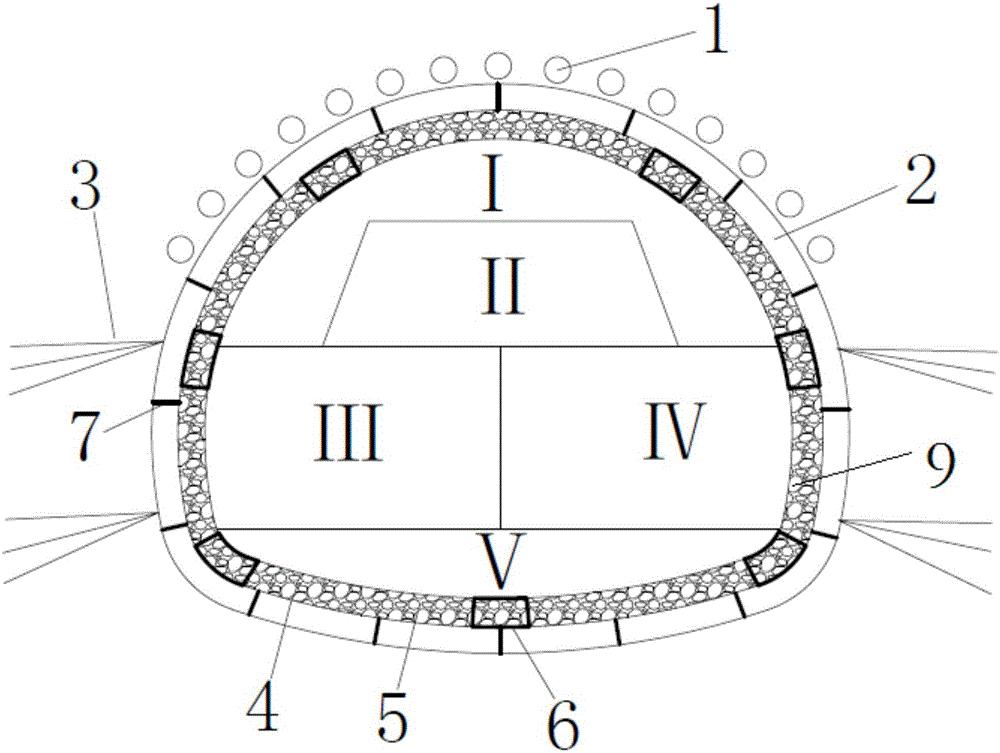

[0036] see figure 1 and figure 2, the present invention includes advanced support, flexible support and rigid support, and the advanced support, flexible support and rigid support are performed in sequence according to the construction procedures, and the advanced support is arranged along the outline of the tunnel arch. 1. The pre-reinforced surrounding rock is formed by injecting cement-sodium silicate double liquid slurry into the surrounding rock through the advanced small conduit 1. The flexible support is assembled by prefabricated foam concrete blocks 2, and the prefabricated foam concrete blocks 2 are connected by bolts. For connection, the joints between all the prefabricated foam concrete blocks 2 are sealed and waterproofed with elastic rubber gaskets 7, and the elastic rubber gaskets 7 are bonded to the prefabricated foam concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com