Ultraviolet aging test method for asphalt material in tension state

An asphalt material, aging test technology, applied in the direction of using stable torsion to test the strength of materials, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problems of poor comparability and reference, and achieve reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

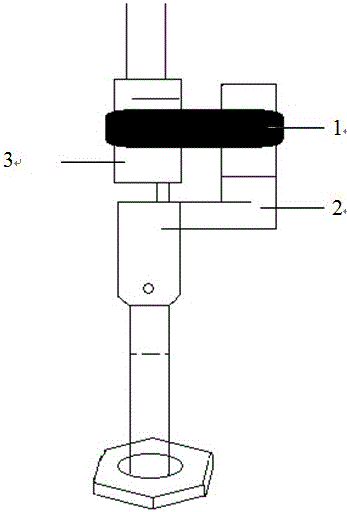

Image

Examples

Embodiment 1

[0029] (1) Determination of the type of ultraviolet light source

[0030] Choose a 1kW high-intensity mercury lamp as the ultraviolet light source, and install a filter to ensure that the surface temperature of the sample is not too high, and maintain the surface temperature of the tested asphalt at 30 °C.

[0031] (2), sample preparation

[0032] SBS modified asphalt was selected as the tested asphalt, and silicone oil paper was used as the release paper. Put the SBS modified asphalt and the applicator in an oven at 170°C and heat it. After the SBS modified asphalt is in a fluid state, stir it evenly. Take about 4g and put it on the silicone oil paper to control the thickness of the asphalt thin layer. One-way paving. In this example, four kinds of SBS modified asphalt samples with thicknesses of 250 μm, 500 μm, 750 μm and 1000 μm were prepared. After the asphalt thin layer is cooled, it is covered with silicone oil paper. Then, it was divided into thin-section sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com