Assembly-type numerical control carving machine based on open-type numerical control system

A numerical control engraving machine and numerical control system technology, applied in the field of mechanical manufacturing technology and equipment, digital control machine tools, can solve the problems of relatively expensive price, complex structure, inconvenient promotion and teaching, etc., achieve low cost, high processing efficiency, suitable for The effect of teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

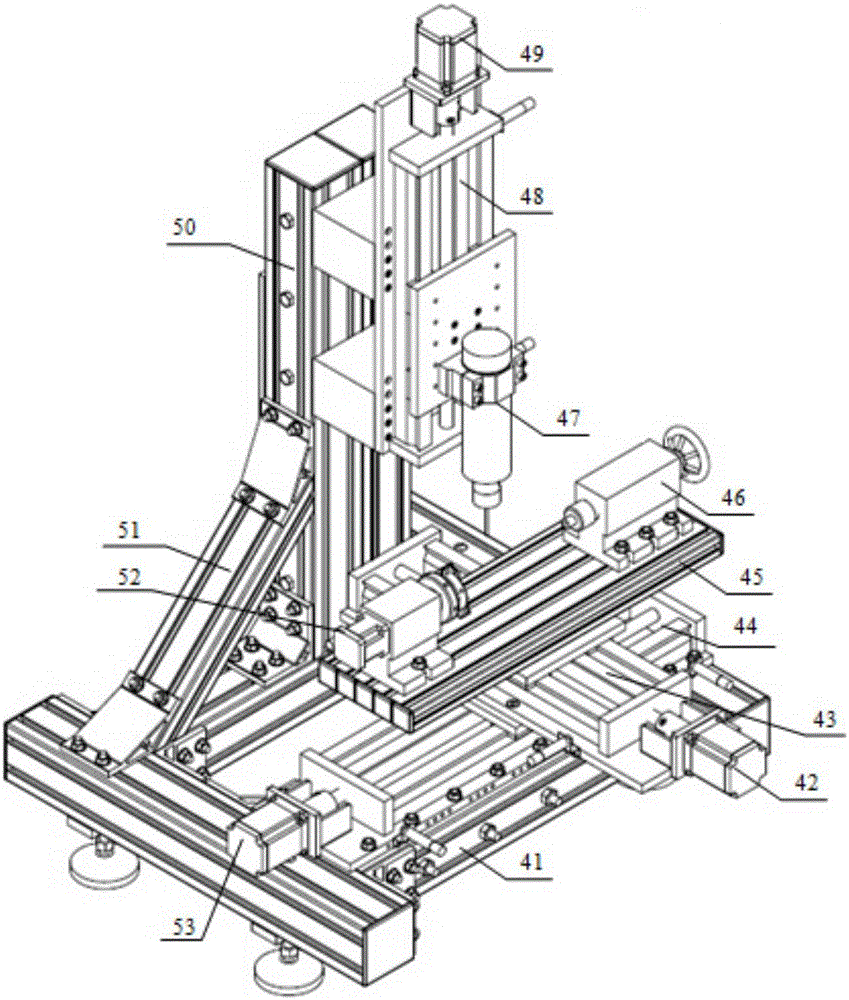

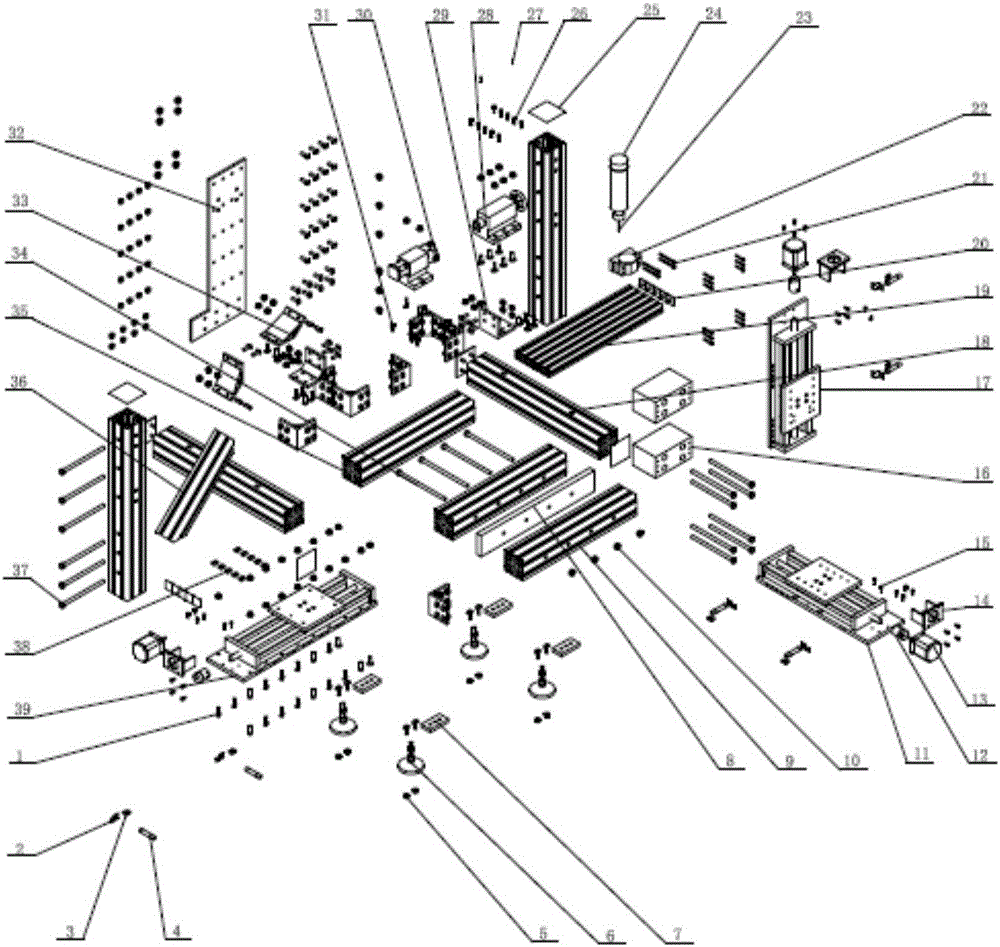

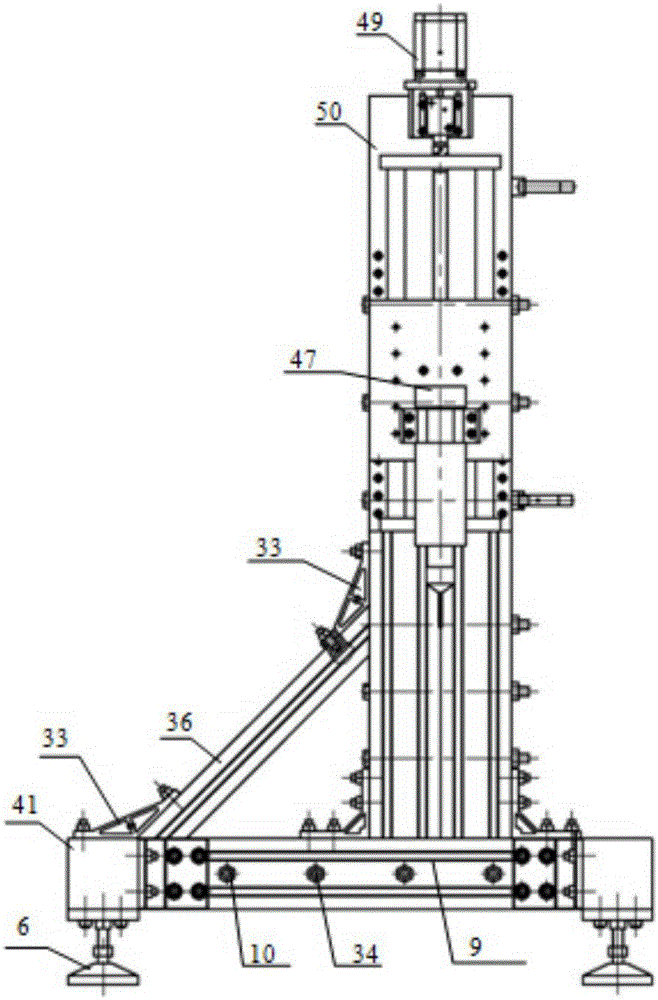

[0037] An assembled CNC engraving machine based on an open CNC system, including three linear axes X, Y, and Z and an A-axis rotary axis, a base, a column, a workbench, a spindle motor, auxiliary supports, an emergency stop switch, and a limit position switch. The three-dimensional engraving is completed by driving the combined movement of each axis through a four-axis motor. The entire engraving machine control system adopts the open CNC system of "PC + high-speed motion control card". Machine height nylon feet. The tool is fixed on the Z-axis and moves up and down with the Z-axis, and the workbench moves horizontally and vertically in the horizontal plane. When the fourth axis is added to the workbench, the workpiece can rotate around X to complete the four-axis three-dimensional engraving process. The invention is especially suitable for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com