Manufacturing method and die for industrial aluminum alloy profile with ultrahigh width-thickness ratio

A technology of aluminum alloy profiles and manufacturing methods, which is applied to the manufacturing method and mold field of industrial aluminum alloy profiles with ultra-high width-to-thickness ratios. High precision and plane precision, improved strength and stability, uniform and reasonable feeding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A method for manufacturing an aluminum profile with an ultra-high width-thickness ratio for industrial use, comprising the following steps:

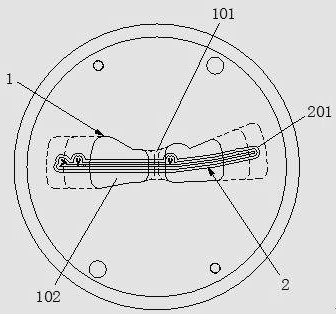

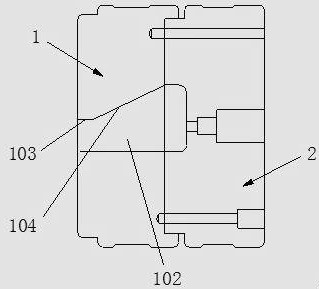

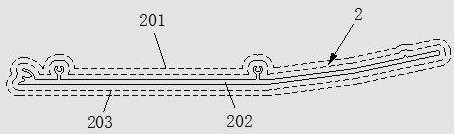

[0063] 1) Making molds for industrial aluminum alloy profiles with ultra-high width-thickness ratios;

[0064] 2) Select pure aluminum ingots with a purity greater than 99.9% as primary aluminum ingots;

[0065] 3) Casting:

[0066] 31) cleaning the original aluminum ingot, and drying the original aluminum ingot in front of the furnace door;

[0067] 32) Send the primary aluminum ingots processed in step 31) into a smelting furnace, use clean energy natural gas as smelting fuel for smelting, and the nitrogen purity required for refining is required to reach 99.99% or more; during the smelting process, control the smelting temperature 720 ℃-750℃, after the metal is completely melted, refining 4 times, each refining for at least 25 minutes, the amount of refining agent used is 2.5Kg / ton, and slag is removed; the furnace temperatur...

Embodiment 2

[0083] A method for manufacturing an aluminum profile with an ultra-high width-thickness ratio for industrial use, comprising the following steps:

[0084] 1) Making molds for industrial aluminum alloy profiles with ultra-high width-thickness ratios;

[0085] 2) Select pure aluminum ingots with a purity greater than 99.9% as primary aluminum ingots;

[0086] 3) Casting:

[0087] 31) cleaning the original aluminum ingot, and drying the original aluminum ingot in front of the furnace door;

[0088] 32) Send the primary aluminum ingots processed in step 31) into a smelting furnace, use clean energy natural gas as smelting fuel for smelting, and the nitrogen purity required for refining is required to reach 99.99% or more; during the smelting process, control the smelting temperature 720 ℃, after the metal is completely melted, refining 4 times, each refining for at least 25 minutes, the amount of refining agent used is 2.5Kg / ton, and slag is removed; the furnace temperature is ...

Embodiment 3

[0105] A method for manufacturing an aluminum profile with an ultra-high width-thickness ratio for industrial use, comprising the following steps:

[0106] 1) Making molds for industrial aluminum alloy profiles with ultra-high width-thickness ratios;

[0107] 2) Select pure aluminum ingots with a purity greater than 99.9% as primary aluminum ingots;

[0108] 3) Casting:

[0109] 31) cleaning the original aluminum ingot, and drying the original aluminum ingot in front of the furnace door;

[0110] 32) Send the primary aluminum ingots treated in step 31) into a smelting furnace, use clean energy natural gas as smelting fuel for smelting, and the nitrogen purity required for refining is required to be above 99.99%; during the smelting process, control the smelting temperature to 750 ℃, after the metal is completely melted, refining 4 times, each refining for at least 25 minutes, the amount of refining agent used is 2.5Kg / ton, and slag is removed; the furnace temperature is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com