Impregnated Ba5Sr(WO6)2 cathode and preparation method thereof

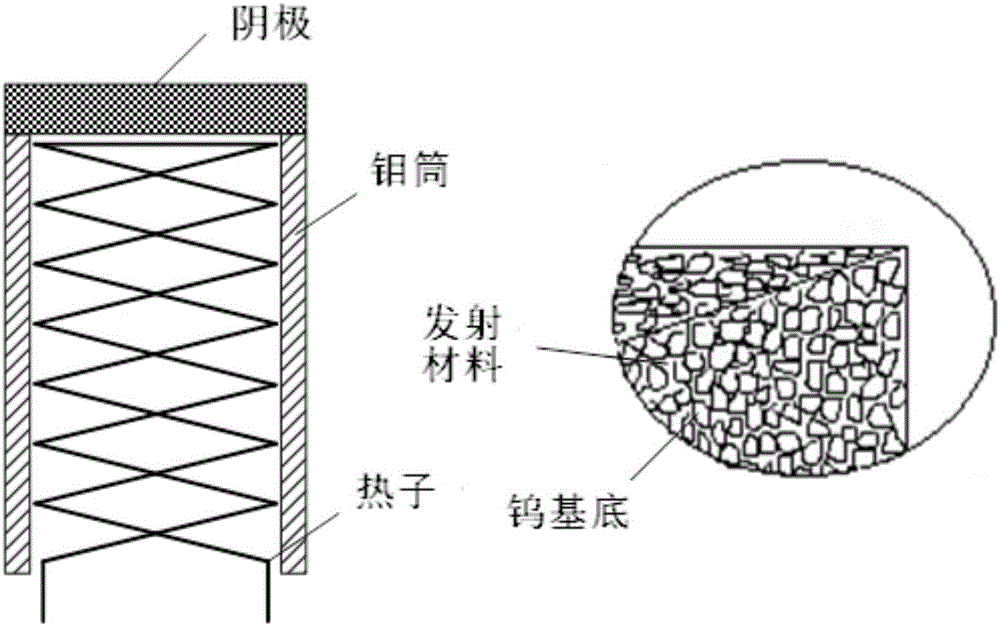

A technology of barium tungstate and cathode, which is applied in the field of electric vacuum, can solve the problems such as difficult practicality of tungstate cathode, achieve the effects of improving cathode reliability, increasing emission current density, and reducing evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

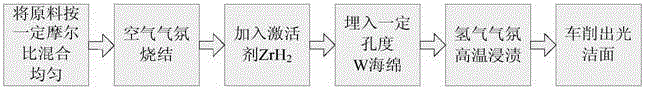

[0029] The process flow chart of the preparation method of the present embodiment is as follows figure 1 shown.

[0030] Specifically, the method for preparing an impregnated barium strontium tungstate cathode in this embodiment includes the following steps:

[0031] (1) BaCO 3 , SrCO 3 and WO 6 After 72 hours of ball milling and mixing at a molar ratio of 5:1:2, at 20kg / cm 2 Under high pressure, the mixed powder material is pressed into a small cake with a diameter of 20mm and a thickness of 2-3mm.

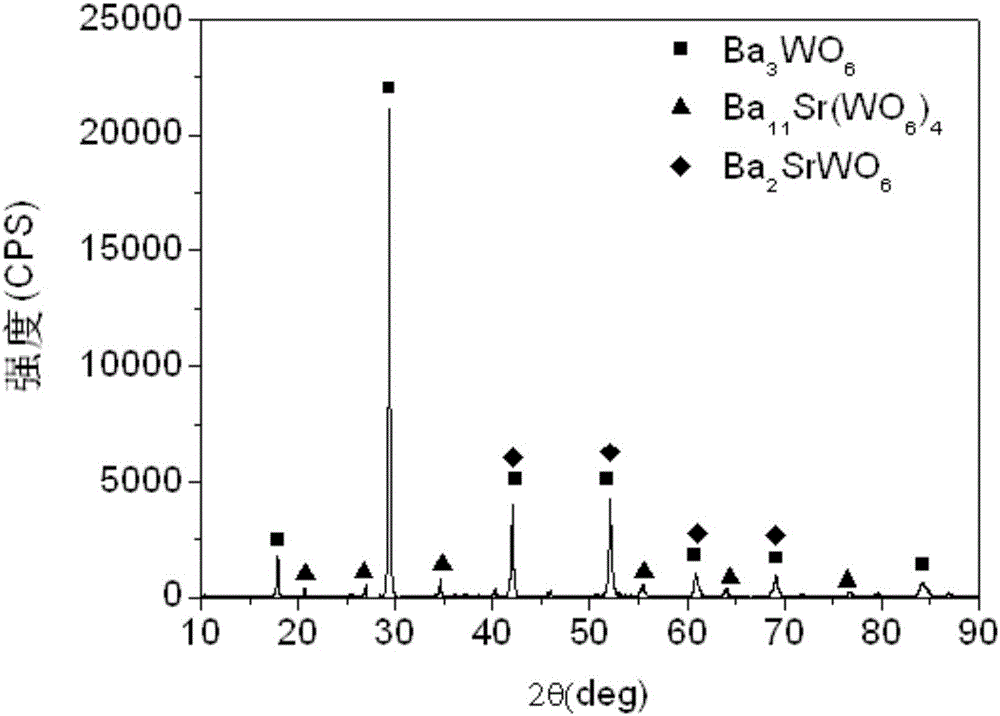

[0032] (2) Put the pressed small cake into the crucible and put it into the muffle furnace with air atmosphere for sintering. First raise the temperature to 400±25°C and keep it for 30 minutes, then gradually raise the temperature to 800±50°C and keep it for 1 hour, and finally raise the temperature to 1400±50°C and keep it for 3 to 4 hours. The main phase of synthesis is barium strontium tungstate (Ba 5 Sr(WO 6 ) 2 ) tungstate, the obtained tungstate XRD analysis results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com