Feeding structure for waveguide slot frequency scanning antenna

A technology of waveguide slots and frequency sweeping, applied in slot antennas, antennas, antenna arrays, etc., to achieve high efficiency, compact and reasonable structure, and high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

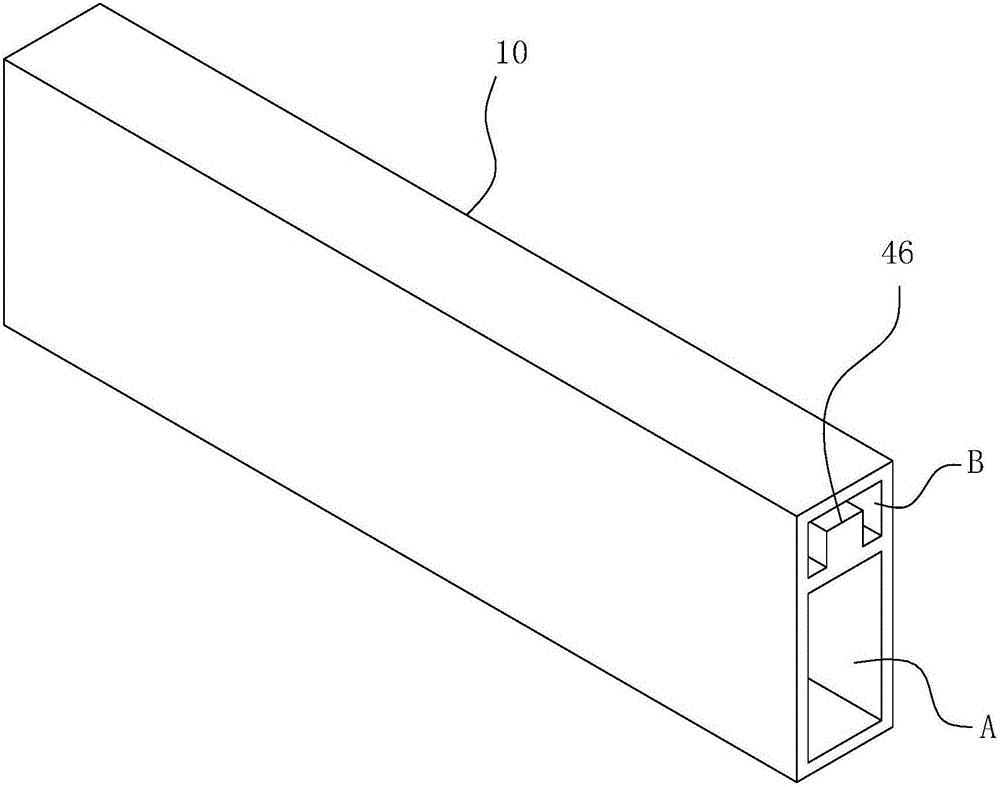

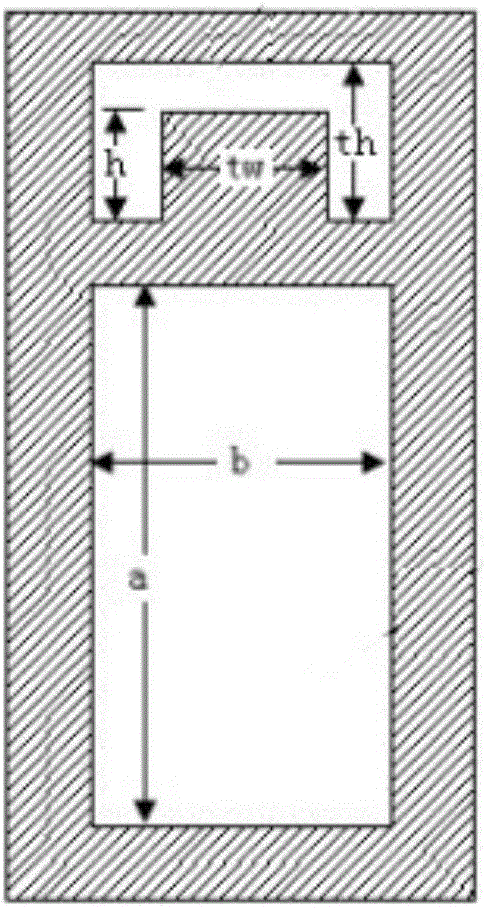

[0040] see figure 2 , the power feed port A is the signal input port, and the first coupling port B is on the same side as the power feed port A; image 3 Dimension drawings for its side view. Depend on image 3 From the middle point of view, the cavity where the cross section of the lower layer is located is a rectangular waveguide layer, where the wide side a=12.95mm and the narrow side b=6.48mm. The cavity where the upper cross-section is located is the ridge waveguide layer, which shares the narrow wall with the rectangular waveguide layer, so the width of the ridge waveguide layer b=6.48mm, the height of the ridge waveguide layer th=4.04mm, the width of the ridge block tw=3.12mm, and the ridge block Height h=2.56mm. And the port size of the other end of the present invention is as Figure 5 As shown, the size of the second coupling port C is exactly the same as that of the first coupling port B, and the size of the feed port A is exactly the same as that of the throu...

Embodiment 2

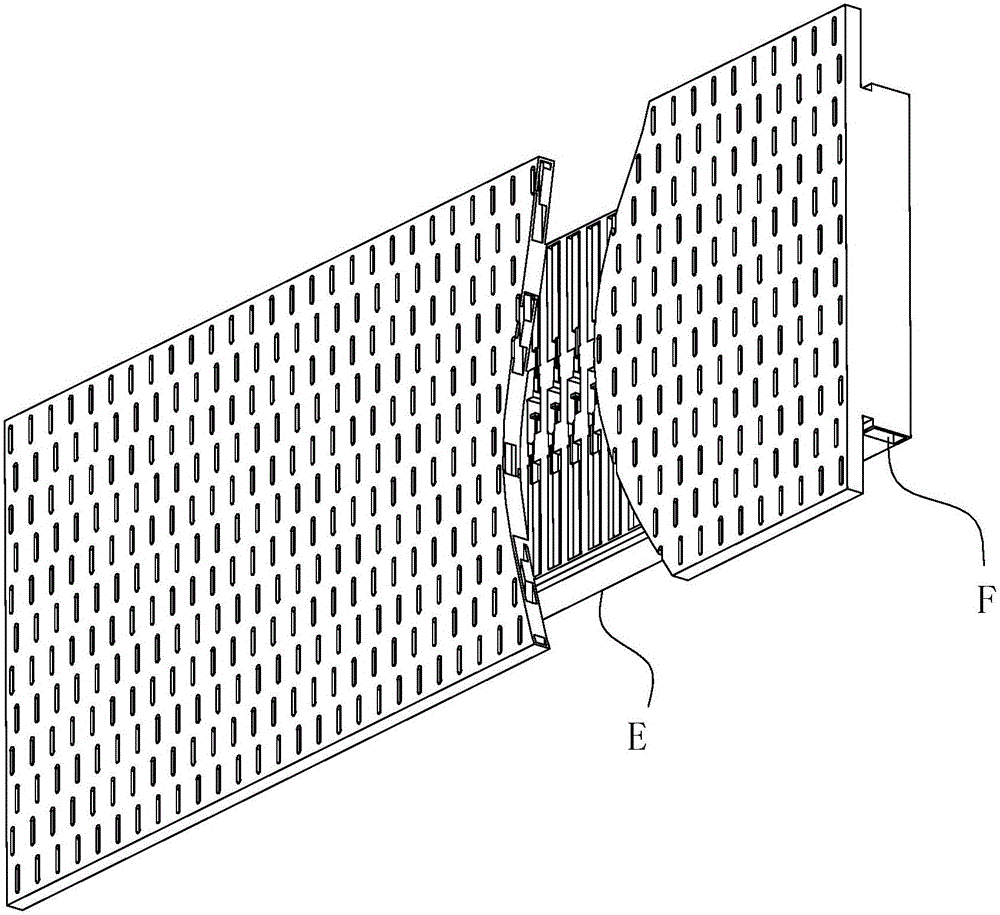

[0052] see figure 1 , is a schematic diagram of the structure of the 42×12 waveguide slot frequency-swept antenna operating in the Ku band of the present invention. In this embodiment, the ridge waveguide wide-side slot antenna is selected as the external radiation antenna, and each column is a 12-element resonant standing wave array. Wherein the feeding structure E formed by the parallel arrangement of the present invention is the same as the feeding structure described in Embodiment 1 in structural appearance and working principle, and the size selection method, range, working principle, etc. of the feeding structure with different coupling coefficients can be implemented by Example 1 and the preceding text are obtained through further data optimization, and will not be described in detail here. When working, the input signal of the antenna is fed through the input port F of the feed network at one end, and the output signal is connected to a matching load through the outpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com