Diced vegetable and fruit stuffed tapioca pearl and making method thereof

A technology of pearl powder balls and production methods, which is applied in the direction of food preparation, application, food science, etc., can solve the problems of single taste, single taste, single taste of powder balls, etc., and achieve the effect of good lubrication, good elasticity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

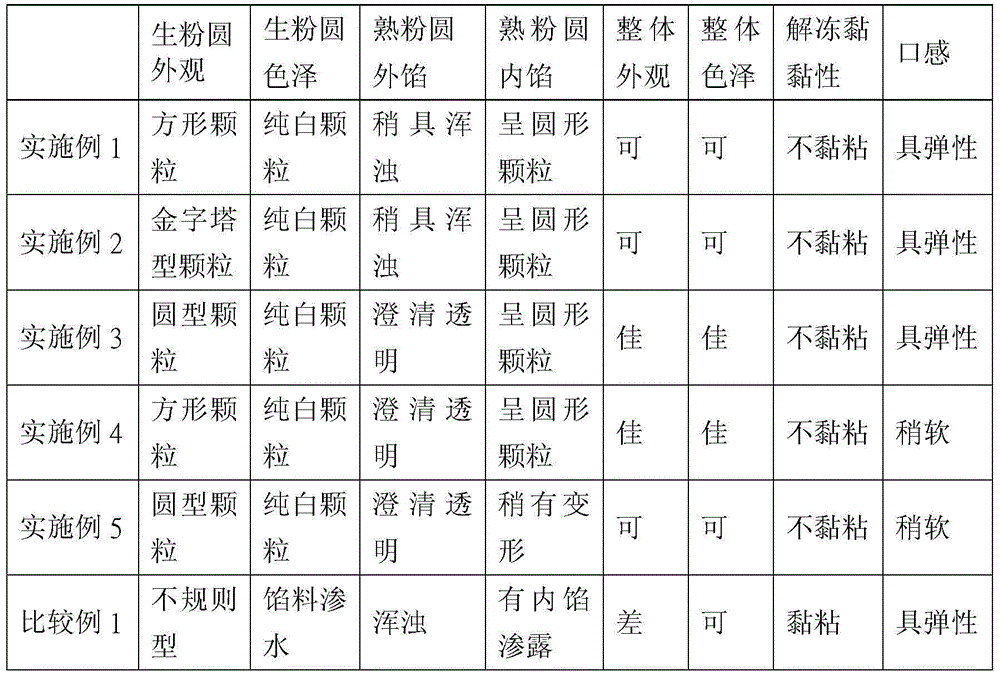

Examples

specific Embodiment 1

[0045] Ingredients for filling: 100% diced apple filling;

[0046] Outer skin materials: 50% tapioca starch, 40% water, 4.2% sugar, 0.8% guar gum;

[0047] Dipping syrup: 100% sorbet syrup with a mass percentage of 70%.

[0048] The fresh apples are peeled and cored and cut into 4 pieces, then the cut apple pieces are cut with a dicing machine to form square particles of 7mm×7mm×7mm into the inner filling particles, and the inner filling particles Put the water, sugar and guar gum into the icing machine at high speed by the high-shear emulsifier to emulsify the colloidal liquid into a uniform colloidal liquid, and then load the colloidal liquid into the high-pressure spray gun to spray the colloidal liquid evenly on the filling particles to make the filling After the surface of the material particles is evenly coated with colloidal liquid, use a powder dispenser to evenly sprinkle the starch on the surface of the coated inner filling particles. This process is about 5 minutes. Repea...

specific Embodiment 2

[0050] Filling material: pineapple diced 100%;

[0051] Skin materials: 50% sweet potato starch, 40% water, 4.2% sugar, 0.8% guar gum;

[0052] Dipping syrup: 100% sorbet syrup with a mass percentage of 70%.

[0053] The fresh pineapple is peeled and cut into 8 pieces, and then the cut pieces of pineapple are cut by a dicing machine into a 7mm×7mm×7mm pyramid to form the inner filling particles, and the inner filling particles are placed in the sugar coating machine In the process, water, sugar and guar gum are emulsified into a uniform colloidal liquid at high speed by a high-shear emulsifier, and then the colloidal liquid is loaded into a high-pressure spray gun to spray uniform colloidal liquid on the inner filling particles to make the surface of the inner filling particles uniform After coating the colloidal liquid, use a powder dispenser to evenly sprinkle the starch on the surface of the coated inner filling particles. This process is about 5 minutes. Repeat the above process...

specific Embodiment 3

[0055] Filling material: horseshoe diced 100%;

[0056] Outer skin materials: 50% acetate cassava starch, 40% water, 4.2% sugar, 0.8% guar gum;

[0057] Dipping syrup: 100% maltose syrup with 70% mass percentage.

[0058] The fresh horseshoes are peeled, and then the horseshoes are cut with a dicing machine into round particles with a diameter of 7mm to become inner filling particles. The inner filling particles are placed in the sugar coating machine, and the water, sugar and guar Soybean gum is emulsified into a uniform colloidal liquid at high speed by a high-shear emulsifier, and then the colloidal liquid is loaded into a high-pressure spray gun to spray uniform colloidal liquid on the inner filling particles, so that the surface of the inner filling particles is evenly coated with the colloidal liquid, and then powdered The starch is evenly sprinkled on the surface of the coated inner filling particles. This process is about 5 minutes. Repeat the above process until the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com